Bonded Neodymium Magnetic Compounds

Bonded Neodymium Magnetic CompoundsIntroductions

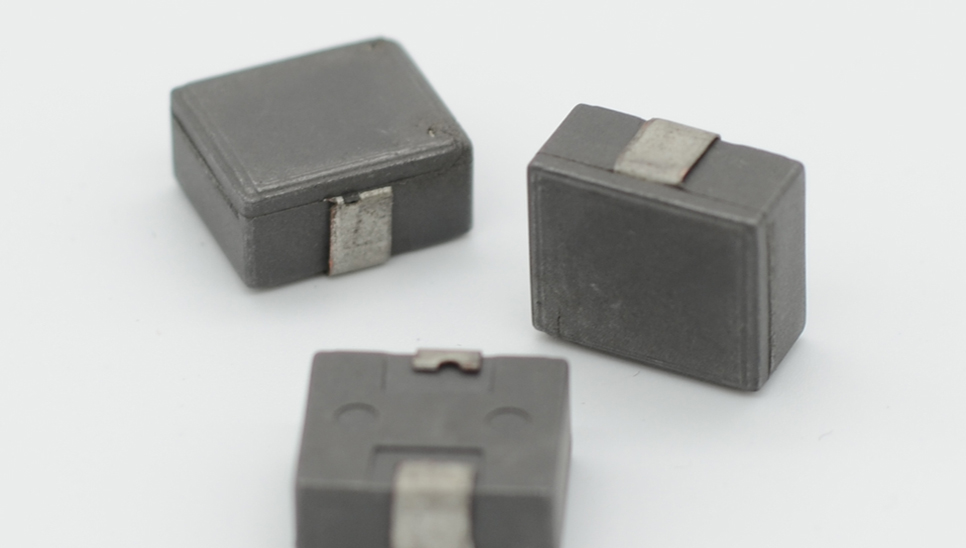

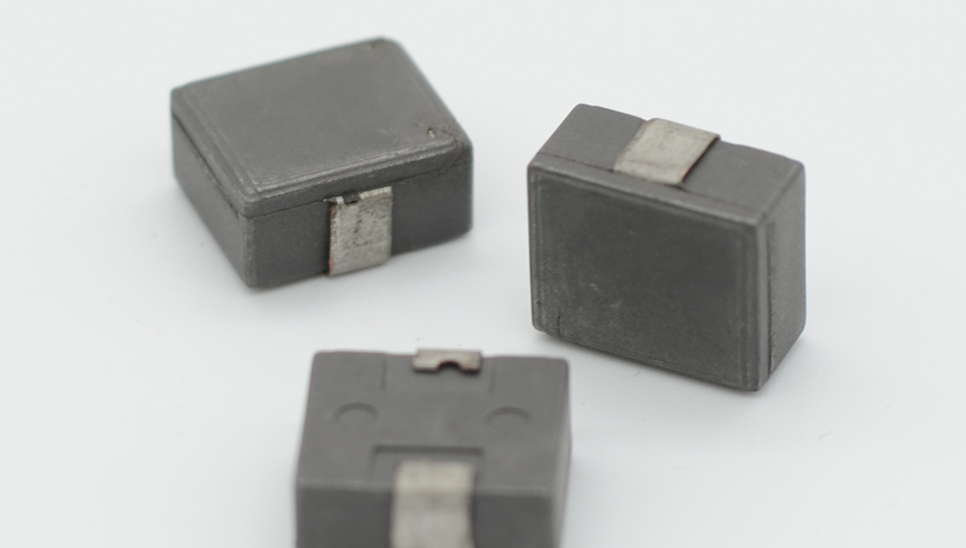

Bonded neodymium magnets(bonded NdFeB magnet) has high mechanical performance and no need for surface coating and other processes, which can effectively avoid the shortcomings of brittle and poor corrosion resistance of sintered NdFeB magnet.

Isotropic bonding neodymium magnets with complex shapes can be obtained through injection molding and subsequent magnetization process, there is no need to apply the magnetic field into an injection mold. Yet, it is necessary for anisotropic bonding neodymium magnets to apply the magnetic field into injection mold to magnetize magnets in a variety of patterns.

A bonded neodymium magnet can be magnetized in the axial, radial, multi-poles, or local direction, which is difficult for sintered NdFeB magnets.

Bonded NdFeB Magnet Material Properties

Several times stronger magnetic property than ferrite bonded magnet contributes to miniaturization and lightweight of parts.

High dimensional precision makes it suitable for precision parts.

The bonded neodymium/NdFeB magnet material can be wholly, partially magnetized, or demagnetized.

Applications of Bonded Neodymium Magnetic Compounds

Motor rotor; micro-sensor; micro-motor; electronic expansion valve; etc.

Specification of Bonded Neodymium Magnetic Compounds

|

Grade |

Br |

HcB |

HcJ |

(BH)max |

neodymium magnet / NdFeB Mold density |

Melt Flow Rate |

IZOD Impact Strength |

Tensile Strength |

Flexural Strength |

Composition |

||||

|

Residual Flux Density |

Coercive Force |

Intrinsic Coercive Force |

Maximum Energy Product |

|||||||||||

|

mT |

Gs |

kA/m |

Oe |

kA/m |

Oe |

kJ/m3 |

MGOe |

g/cm3 |

g/10min |

kJ/m2 |

MPa |

MPa |

||

|

NB25 |

353 |

3530 |

247 |

3098 |

725 |

9112 |

1000 |

25 |

53 |

95 |

NdFeB+PA12 |

|||

|

NB30L1 |

381 |

3810 |

256 |

3211 |

671 |

8431 |

800 |

10 |

40 |

75 |

||||

|

NB40 |

455 |

4550 |

300 |

3769 |

697 |

8760 |

900 |

14 |

51 |

90 |

||||

|

NB50 |

503 |

5030 |

325 |

4078 |

647 |

8132 |

400 |

11 |

50 |

85 |

||||

|

NB70 |

592 |

5920 |

370 |

4647 |

681 |

8549 |

860 |

8 |

45 |

88 |

||||

|

NB80 |

647 |

6470 |

384 |

4829 |

589 |

7401 |

335 |

8 |

55 |

100 |

||||

|

NC15 |

276 |

2760 |

195 |

2453 |

679 |

8531 |

1200 |

9 |

40 |

105 |

NdFeB+PPS |

|||

|

NC20 |

336 |

3360 |

235 |

2946 |

656 |

8241 |

1200 |

9 |

40 |

110 |

||||

|

NC30 |

370 |

3700 |

266 |

3346 |

943 |

11840 |

1000 |

8 |

44 |

110 |

||||

|

NC30L |

384 |

3840 |

264 |

3310 |

680 |

8548 |

900 |

8 |

45 |

110 |

||||

|

NC40H |

447 |

4470 |

312 |

3915 |

899 |

11295 |

400 |

6 |

53 |

87 |

||||

|

NC50 |

500 |

5000 |

340 |

4274 |

877 |

11023 |

200 |

6 |

48 |

88 |

||||

|

NC60 |

533 |

5330 |

372 |

4672 |

899 |

11290 |

150 |

6 |

43 |

83 |

||||

|

HNB120a |

786 |

7860 |

461 |

5790 |

860 |

10800 |

500 |

12 |

48 |

86 |

HDDR +PA12 |

|||

|

HNB140a |

821 |

8210 |

501 |

6290 |

1003 |

12600 |

113 |

400 |

7 |

47 |

83 |

|||

MFR Test Condition: NB/HNB series (270℃, 10kg); NC series (310℃, 10kg).

Chase technology is a national high-tech enterprise, which was founded in 2011 and located in Hangzhou, Zhejiang China. We provide ndfeb magnet density, bonded neodymium, bonded ndfeb, best magnetic materialand etc. Want to know neodymium iron boron magnet propertiesor more? Contact us.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Bonded SmFeN Magnetic Compounds | Introduction SmFeNmagnetic material uses abundant rare-earth Sm element instead of expensive elements of Nd, Dy, Co, etc, and is the most cost-e... | |

| Soft Magnetic Bonded Compounds | Soft Magnetic Bonded Compounds As a new material, soft magnetic compoundcan be used for extrusion or injection molding and are especially suitable... | |

| Hard-Ferrite Bonded Magnetic Compounds | Light density and low cost of ferromagnetic compounds(hard ferrite magnets) create a high-cost performance. Therefore, it has the largest market de... | |

| Magnetic Solution For Famous Customers | We can provide customers with appropriate mold design scheme (magnetic circuit design and mold-flow analysis) and optimization processing parameter... | |

| Soft Magnetic Bonded Compounds | Soft Magnetic Bonded Compounds As a new material, soft magnetic bonded compounds can be used for extrusion or injection molding and are especially ... |