Dry Ball Mill

Dry ball millis suitable for all kinds of metal and nonmetal ores, including materials that will react with water, such as cement, marble, and other building stones, or products that require storage and sales in the form of powder. In addition,among all ball grinding machine, if the concentrator is located in an arid area and water resources are scarce, dry grinding ball mill can be used for water saving.

Advantages of Dry Grinding Ball Mill

Dry ball mill need less water, which greatly saves water consumption compared with wet ball mill.

The material produced by dry ball mill is the finished product.

The efficiency of dry ball mill is higher.

Available for cement ball mill.

Working Principle of Dry Ball Mill

The dry grinding ball mill is a horizontal cylindrical rotating device, which is driven by outer gear. It is divided into lattice type dry ball mill and multi-bin type dry ball mill. The material enters into the front bin of the mill through the feeding device, and the hollow shaft screw evenly enters into the front bin of the mill. There are stepped lining plates or corrugated lining plates in the bin, which are filled with steel balls of different specifications. The rotation of the cylinder generates centrifugal force to bring the steel balls to a certain height and then fall down, which has a heavy impact and grinding effect on the material. After rough grinding in the front bin, the materials enter the second bin through a single-layer partition board. The bin is inlaid with a flat lining board and steel balls to further grind the materials. The powder is discharged through the discharging grate plate to complete the industrial grinding mill operation.

Main Structure of Dry Ball Mill

Feeding screw for feeding raw material.

The shell is equipped with a manhole for maintenance and replacement of the inner liner.

Discharge part for ball mill to discharge qualified products.

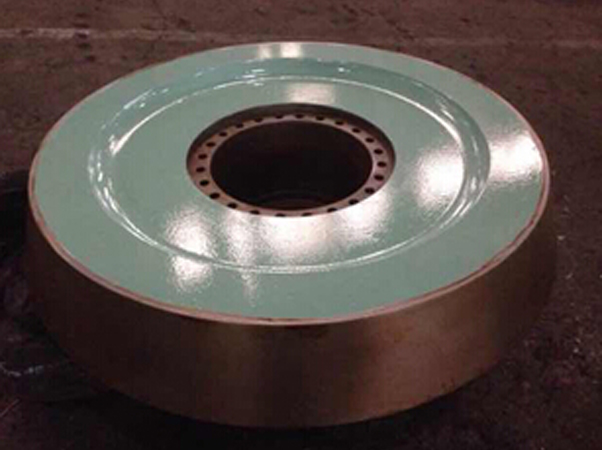

Main bearing.

Transmission part.

Operation and Maintenance of Dry Ball Mill

Before the ball mill is started, check whether the connecting bolts are tightened, including gears, couplings, etc. Check whether the oil tank and reducer have enough quantity; Whether the whole lubricating device and instrument are defective and whether the pipeline is smooth. Finally, check whether there are any sundries around the ball mill and classifier. Only if everything is clear can we get the ball mill to work.

Intelligent Grinding Expert System Ball Mill

To realize the intelligent control for ball mill operation, we provide the intelligent grinding expert system. It will monitor the situation of ball mill working and the finished products status. Lower the labour cost with great efficient.

Technical Parameters of Dry Ball Mill

|

Specification |

Capacity |

Rotary Speed |

Input Size |

Grinding Medium Load |

Volume |

Motor |

Profile Dimensions(L×W×H) |

Total Weight |

Remarks |

|

|

m |

t/h |

r/min |

mm |

t |

M3 |

Power/kw |

Voltage/V |

mm |

t |

|

|

φ2.2×6.5 |

15-16 |

22 |

<20 |

22 |

18 |

320 |

6000 |

52 |

||

|

φ2.2×8 |

30 |

<25 |

45 |

560 |

6000 |

81 |

||||

|

φ2.2×13 |

29-30 |

<25 |

60 |

43 |

630 |

6000 |

||||

|

φ2.2×13 |

24-35 |

<25 |

60 |

43 |

630 |

6000 |

113 |

|||

|

φ2.2×13 |

40 |

<25 |

65 |

50 |

800 |

6000 |

145 |

|||

|

φ3×9 |

36-42 |

<25 |

70-80 |

1000 |

6000 |

|||||

|

φ3×11 |

60-65 |

<15 |

90-100 |

69 |

1250 |

6000 |

180 |

|||

|

φ3.2×7+1.8 |

48-63 |

18 |

<20 |

55-58 |

1000 |

6000 |

||||

|

φ3.4×7+1.8 |

54 |

<20 |

65 |

1000 |

6000 |

(22.057+a)×5.12×4.23 |

a is the length of the motor |

|||

|

φ3.4×7.5+1.8 |

~60 |

<20 |

70 |

1250 |

6000 |

214-217.5 |

||||

|

φ3.5×10 |

75 |

<20 |

80 |

1250 |

6000 |

270 |

||||

|

φ3.5×9 |

90-95 |

<15 |

130 |

94 |

2000 |

6000 |

||||

|

φ3.8×8.5+3.5 |

~90 |

<20 |

100 |

1600 |

6000 |

|||||

|

φ4.8×8.5+3.5 |

150 |

15 |

<20 |

150 |

2800 |

|||||

|

φ4.6×10+3.5 |

190 |

15 |

<25 |

190 |

157 |

3550 |

352 |

|||

|

φ4.6×9.5+3.5 |

185 |

<25 |

175-180 |

148 |

3550 |

6000 |

293 |

|||

|

φ4.6×14 |

185-220 |

15 |

210 |

185 |

4200 |

310 |

||||

As one of heavy equipment dealers, we will do our best to meet all the needs of clients.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Rotary Kiln | CIC’s equipment includes leading standardized heavy equipment and machinery products and related heavy machinery services, which can be sold ... | |

| Horizontal Centrifuge | TWZ series horizontal vibratory centrifuge belongs to the centrifugal dewatering machine, the series of horizontal vibratory centrifuge is mainly u... | |

| Dry Ball Mill | Dry ball mill is suitable for all kinds of metal and nonmetal ores, including materials that will react with water, such as cement, marble, and oth... | |

| SAG Mill | Semi autogenous mills or SAG mills as they are often called, can perform grinding operations equivalent to two or three stages of crushing and scre... | |

| Thrust Roller | CIC is a more than 30-year manufacturer and reputed supplier of thrust rollerused in rotary kilns, rotary type driers and so on. CIC has been speci... |

Похожие товары

| LEN503 Nebulizer | Продавец: Lepu Medical Technology(Beijing)Co.,Ltd | Cute pet caring Small atomized particles nebulizer machine for kids Adjustable atomizing cup H... | |

| SINOART Shanghai Co., Ltd. | Продавец: SINOART Shanghai Co., Ltd. | SINOART Shanghai Co., Ltd. is a combined industrial & trading company in China, specializing ... | |

| FPQ2W-10/3T20 10kV Pin Insulators | Продавец: Guangdong Yufeng Industries Co.,Ltd | The crimping process of polymer pin type insulatorsshould pay attention to the crimping force, co... | |

| Гондурас Резервуар с жидким азотом для искусственного осеменения KGSQ Колба Дьюара | Продавец: Хэнань Тяньчжидао Биотехнология Лтд. | Резервуары с жидким азотом для скота широко используются в племенной отрасли, особенно при замора... | |

| Резервуар для спермы Дьюара с жидким азотом в Бурунди KGSQ | Продавец: Henan Tianzhidao Biological Technology Co., Ltd. | Резервуары с жидким азотом для скота широко используются в племенной отрасли, особенно при замора... |