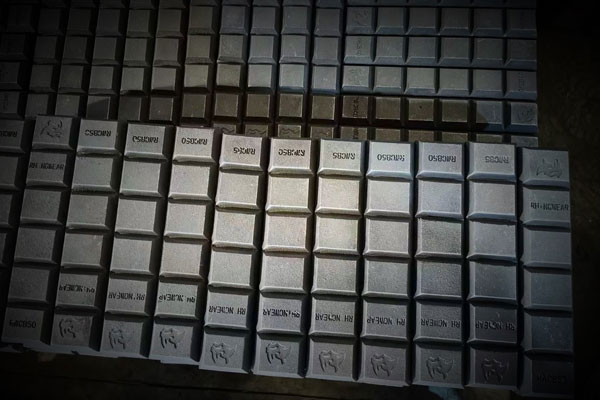

Teeth

Walkson provides custom made big ground engaged tools (G.E.T), supplies small wheel loader bucket teethand dragline teeth. The excavator teethcan be castings and close die forging parts.

Mechanical property of the cast teeth as below:

|

Hardness HRC |

48~52 |

|

AKV @20℃ |

≥17J |

|

AKV @-40℃ |

≥12J |

For the normal non- hammerless version, we have forged version. The quality of forged teeth is more stable compared with other ground engaging teeth, and the dimension is more accurate.

Mechanical property of the forged teeth as below:

|

Hardness HRC |

50~52 |

|

AKV @20℃ |

≥25J |

|

AKV @-40℃ |

≥20J |

Benefits of Teeth

WALKSON, specializing in ground engaging tools mining, has an incredibly good control of the manufacture processes which is the key factor that we can provide high quality products. The main measures to ensure good products are made as below.

Good methods designing-Experienced methods engineer assisted with the FEM software, good cast methods can be designed for our products.

Best pattern tooling designing-our designing of the pattern tooling is very practical and can get rid of a lot of potential quality issues during the manufacture process.

Strict processes operation control-our shopfloor operation is conducted strictly according to the methods card and work instruction. As we believe the quality is produced, not test out.

Advanced melting equipment-E.A.F and A.O.D are the key equipment to make high quality iron sand casting process. The gas content in the steel can be controlled under extremely low level.

Professional heat treatment-The heat treatment methods, the loading methods, the capacity of the quench tank, the speed of agitation system, all of these are under our control.

Final dimension inspection experience in gauging designing and manufacture process, make sure the batch production products are all inspected and comply with dimension requirement.

Walksonis a professional manufacturing as a service companies,we provide steel foundry china, chrome carbide overlay, track shoes, etc. We are committed to delivering high-quality products and services to your design and specification with Max.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Bubble Shaft | WALKSONcan provide forged shafts, forged Crankshafts and forged stepped/bubble shafts of carbon steel, alloy steel, stainless steel, titanium, nick... | |

| Ground Engaging Tools | Ground engaging tools definition: Ground Engaging Tools (G.E.T) are wear parts with high impact and high abrasion resistance ability. High-performa... | |

| Chocky Wear Bars, Wear Buttons | The unique, formable design of Chocky wear bars and wear buttonare available in various lengths, grades and sizes and can also be customized as per... | |

| Ball Valve | WALKSON, as a reliable electric ball valve company, supplies main parts for high temperature ball valve, consisting of Valve Body, ball, stem and s... | |

| Hot Forging | Hot forging is also called hot die forgingby hot forging manufacturers. During the hot die forging process, the deformed metal flows violently and ... |

Похожие товары

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Продавец: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Продавец: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... | |

| 3 in1 Decoiler Leveler Feeder | Продавец: Dongguan YouYi Precision Automation Equipment Co., Ltd. | 3 in1 Decoiler Leveler Feeder For Thin Plate(0.3-3.2mm) The 3-in-1 servo feederintegrates four f... | |

| NC Servo Feeder (0.1-3.0mm) | Продавец: Dongguan YouYi Precision Automation Equipment Co., Ltd. | NC Servo Feeder (0.1-3.0mm) Our standard servo feederis engineered for precision coil feeding of... | |

| Uratech 40 Taper CNC Tower – CAT 40 Tool Cart & CNC Tool Holder Storage | Продавец: Uratech USA Inc | TheUratech 40 Taper CNC Toweris the ultimate solution for organizing and protecting your CNC tool... |