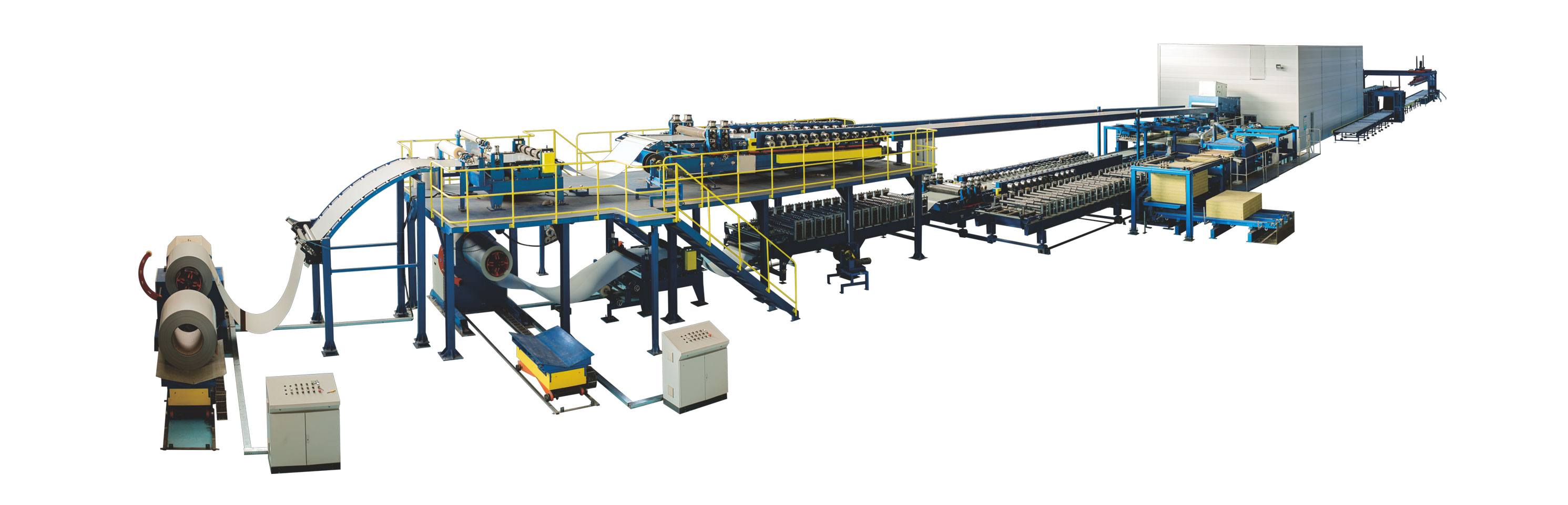

Rockwool Continuous Sandwich Panel Production Line

The rockwool sandwich panel production lineis one continuous and automatic line that integrates mechanism, electrical controlling, hydraulic system and polyurethane chemical reaction technology. The rock wool sandwich panel machineadopts advanced international roll forming technology, digital servo technology, frequency conversion vector technology and hydraulic controlling technology, automatic stacking technology.

The advantages of this mineral wool sandwich panel machineare the following:

1) High automatization. The wholerockwool productionline adopts one full computer integration controlling system of digital servo technology, frequency conversion vector technology and hydraulic controlling technology, which realizes whole connection, collecting control and collecting management. Adopt the cutting style of cut to length without machine stop, so that realize full automatically.

2) High efficiency. The production speed of rockwool sandwich panel machine is 3~8m/min(adjustable according to product forming requirement). The annual product capacity of this line can reach to 800000 M2 (count on the base of 250work days per year and 10 work hours per day)

3) Easy operation. Adopt collecting controlling system, using man-machine conversation. After preparing for the raw material and finishing other production requirements, input required parameters, then the machine can make the product automatically.

4) Low production cost. Developing the machine's automatization, the whole line only needs 5-8 operators to operate the machine fully, which saves much labor cost and production management cost for enterprises.

Video of mineral wool sandwich panel production lineRock wool Continuous Sandwich Panel Production Line

Zhejiang JinggongScience and Technology Co., LTD., independently research, develop, and manufacture the PU/Rockwool sandwich panel continuous production line, which reaches the world's advanced technology, fills the blank of domestic PU/Rockwool production line manufacturing. It marks the coming of the era of localization of the PU/rock wool sandwich panel continuous production line. The PU/rock wool sandwich panel continuous production line manufactured by Zhejiang Jinggong Science and Technology Co., LTD. consists of the coiler system, filming, cutting, and slitting device, roll forming system, pre-heating device, rockwool system, rockwool upper and lower adhesive spraying system, pu side seal foaming machine, double belt system, double belt heating system, bandsaw system, stacker system, packing system, etc. It truly realized all the automatic integration production functions from pre-painted steel sheet decoiling to product's packaging. The maximum speed of this production line reaches 8 meters per minute, annual production of PU panel 1 million square meters.

The whole production line is exported to Jordan, Kuwait, Tonicia, Russia, Brazil, Argentina, UAE, India, and other countries. The performance of the production line got unanimous approval and favorable comments from the customers. With the development of the construction industry, PU side seal rock wool sandwich panel will be more widely used in construction field. Jinggong Science and Technology will provide the best products and top quality service to the general customers by using most sophisticated manufacturing and technology, also make our own contribution for national and even global environmental protection, energy conservation.

Main Parameters ofRockwool Continuous Sandwich Panel Production Line

Sandwich panel specification:

Length: Min cutting length is 2.5 m

Max cutting length is 12m

Width: (see profile drawing)

Thickness: (see profile drawing)

Raw material specification:

coil thickness: 0.4~0.6 mm (steel be flat without ups and downs, deformation and bending)

sheet yield stress: ≤235MPa

coil max width: 1250 mm (tolerance±2mm)

coil max weight: 5T

coil ID: Φ500 and Φ600 mm

coil OD: Φ1000 mm

Rock wool material: fiber length is >100mm, and the fiber should be arranged vertically, volume density is ≥70kg/m3, one-piece length is ≥3m.

EPS material: volume density is ≥18kg/m3, each edge nonstraightness is ≤1mm/m, radian is ≤3mm/m, the panel surface should be flat, roughness is <1.5mm/m, EPS panel one-piece length is ≥3m.

EPS material width: min width is 1/2mm of the sandwich panel width.

Machine rockwool specification:

Work line speed: 4000m/min (adjustable)

Machine length: about 70 m

Working height: 1050 mm(panel output height)

Laminating effective length: 7.5m

Control way: adopt industrial computer PLC

Total power: about 45 kw

Power: 380V/3phase/50 Hz

control voltage: 24 V/110 V/220 V

pneumatic: 0.7 Mpa (self-prepared by the factory)

best working temperature: around 25℃

Component List ofRock Wool Sandwich Panel Production Line

|

Component |

Qty |

Remarks |

|

|

1 |

5T passive decoiler (upper forming system) |

1set |

Loading capacity is ≤5t |

|

2 |

Upper roll forming machine |

1set |

With slitting and waste edge winder |

|

Lower roll forming machine |

1set |

||

|

Connecting roller of upper & lower forming system |

Each 1set |

||

|

Platform, stair and rail of upper roll forming machine |

1set |

||

|

3 |

Rock wool transfer device |

1set |

|

|

Rock wool edge cutting device |

1set |

||

|

Dust collector |

1set |

||

|

4 |

Rock wool clamp device |

Each 1 set |

|

|

5 |

Laminator host |

1set |

Effective length 7.5m |

|

6 |

Saw cutting system |

1set |

Upper & lower saw |

|

7 |

Support frame |

3sets |

|

|

8 |

Electric control system |

1set |

Panel Drawings Of Rockwool Continuous Sandwich Panel Production Line

Profiles of Rockwool Continuous Sandwich Panel Production Line

application: stone/concrete/rock wall panel, cold storage wall, aluminum foil surface decoration, rock wool panel with PU sealing, door panel, tile roof panel, rockwool box type wall, PU soft surface panel, PU roof panel.

Zhejiang Jinggong Science and Technology Co., Ltd.is a professional roll forming machine company, Jinggongprovides rollforming machines, sandwich panel machinery, etc.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| EPS Sandwich Panel Production Line | Main structure features ofEPS Sandwich PanelMachine 1) This EPS sandwich panel making machinehas the specification: nice appearance, low noise and... | |

| PU/PIR Continuous Sandwich Panel Production Line | Continuous PU Sandwich Production Line, also calledpolyurethane sandwich panel manufacturing linemachine, is an automatic production line, which is... | |

| Steel Structure Machine | Jinggongcan produce various kinds of steel frame machineto match customer's requirements and develop the technology continuously. The main steel s... | |

| Digital Folder&Slitter | This Digital Folder&Slitter is the high&new technology product developed by our company and Hayes company from New Zealand. It is integrate... | |

| Roll Forming Machine | Having made automatic china roll formerfor over twenty years, we are a professional china roll forming machine factoryin this area with rich experi... |

Похожие товары

| Waste Aluminum Plastic Pyrolysis Plant | Продавец: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... | |

| Continuous Tire/ Rubber Powder Pyrolysis Plant | Продавец: Shangqiu Sihai Energy Technology Co.,Ltd | Continuous Tire/ Rubber Powder Pyrolysis Plant Pyrolysis is the process of heating organic mater... | |

| Herbicide Supplier | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Herbicide Supplier Wholesale Herbicide Suppliers - Laike Biotech is a professional supplier ... | |

| Press Fit Machine | Продавец: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Press Fit Machine Mainly used in the semiconductor packaging industry, it can be used for variou... | |

| Tri-Temperature Test Product | Продавец: Guangzhou Top-leading Intelligent Technology Co.,Ltd | Tri-Temperature Test Product Mainly used in the semiconductor packaging industry, it can be used... |