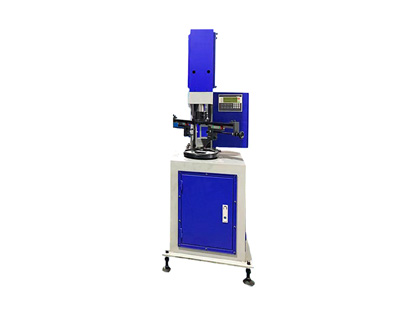

SEAM WELDER

Seam welding equipmentrefers to a resistance welding machine in which the weldment is assembled into a lap or butt joint and placed between two roller electrodes, the roller electrode pressurizes the weldment and rotates, and the continuous or intermittent pulse power transmission forms a continuous weld. It can also be said that the seam welder is an evolution of spot welding. Automatic seam welderis widely used in the manufacture of joints requiring sealing, and sometimes used to weld ordinary non sealing sheet metal parts. The thickness of the metal material to be welded is usually 0.1~2.5mm.

DIFFERENT TYPES OF SEAM WELDER FROM XIHE

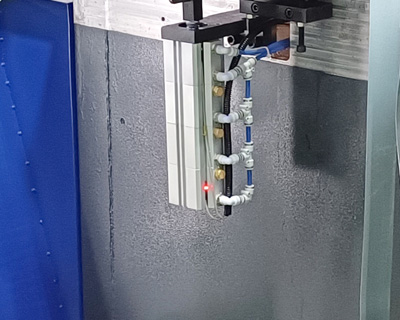

Laser Seam Welding

The roller seam weldingis an automatic equipment that integrates the automatic completion of multiple processes of rounding, cutting, welding and forming. High efficiency and low cost.

IS SEAM WELDER STRONG?

During the seam welding process (intermittent) seam welding, each solder joint also goes through three stages of pre-pressing, heating by heating and cooling and crystallization. However, due to the rapid change of the relative position between the roller electrode and the weldment during seam welding, these three stages are not as obvious as those in spot welding. It can be considered that: 1) Under the direct pressing of the roller electrode, the metal being heated by electricity is in the "electric heating stage". 2) The adjacent metal that is about to enter under the roller electrode is subjected to certain preheating and partial pressure of the roller electrode, and it is in the "pre-pressing stage". 3) The adjacent metal that has just come out from under the roller electrode starts to cool on the one hand, and at the same time is subjected to the partial pressure of the roller electrode, which is in the "cooling and crystallization stage".

ADVANTAGES OF SEAM WELDER

1

Like spot welding, seam welding is a welding process under the combined action of thermal mechanical (force). In comparison, the mechanical (force) effect is insufficient in the welding process (except for step seam welding), and the faster the welding speed is, the more obvious it is.

2

The seam weld is composed of overlapped welding points, so the shunting during welding is much more serious than that of spot welding, which makes it difficult to weld thick plates of high conductivity aluminum and magnesium alloys. The surface of the roller electrode is easy to be damaged and the surface quality of the weld is deteriorated. Therefore, the electrode dressing is a particularly noteworthy problem.

3

Since the cross-sectional area of the seam weld is usually more than twice the longitudinal load area of the base metal (the thinner the plate, the greater the ratio), the damage must occur in the heat affected zone of the base metal. Therefore, the joint strength of seam welded structure is seldom emphasized, and it is mainly required to have good sealing and corrosion resistance.

As one of the most professional seam welder manufacturers, we provide laser welder, seam welding sheet metal, longitudinal weld seam, laser welding system, etc. For milling machine speedor more, contact us.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| ENAMEL POT STAINLESS STEEL BELT CRIMPING MACHINE | ENAMEL POT STAINLESS STEEL BELT CRIMPING MACHINE The equipment is designed for crimping and forming after welding of stainless steel rings of enam... | |

| PAPER DRUM STAINLESS STEEL BELT LASER WELDER | The equipment is mainly aimed at the stainless steel of the paper drum, which is made of galvanized material, and the laser welding technology is a... | |

| FOOD STEAMER STAINLESS STEEL BELT PRODUCTION LINE | This equipment is specially customized for the steamer industry, and realizes the automatic production of welding and forming of stainless steel st... | |

| AUTOMATIC POLISHING MACHINE | Theconcrete grinding and polishing machine, also known as the automatic polishing machine, is a state-of-the-art piece of equipment that utilizes a... | |

| CNC MILLING MACHINE | The equipment is a CNC milling machine developed and produced for the milling processing of the forklift brake base plate boss. The equipment can r... |

Похожие товары

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | Продавец: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | Продавец: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... | |

| 3 in1 Decoiler Leveler Feeder | Продавец: Dongguan YouYi Precision Automation Equipment Co., Ltd. | 3 in1 Decoiler Leveler Feeder For Thin Plate(0.3-3.2mm) The 3-in-1 servo feederintegrates four f... | |

| NC Servo Feeder (0.1-3.0mm) | Продавец: Dongguan YouYi Precision Automation Equipment Co., Ltd. | NC Servo Feeder (0.1-3.0mm) Our standard servo feederis engineered for precision coil feeding of... | |

| Uratech 40 Taper CNC Tower – CAT 40 Tool Cart & CNC Tool Holder Storage | Продавец: Uratech USA Inc | TheUratech 40 Taper CNC Toweris the ultimate solution for organizing and protecting your CNC tool... |