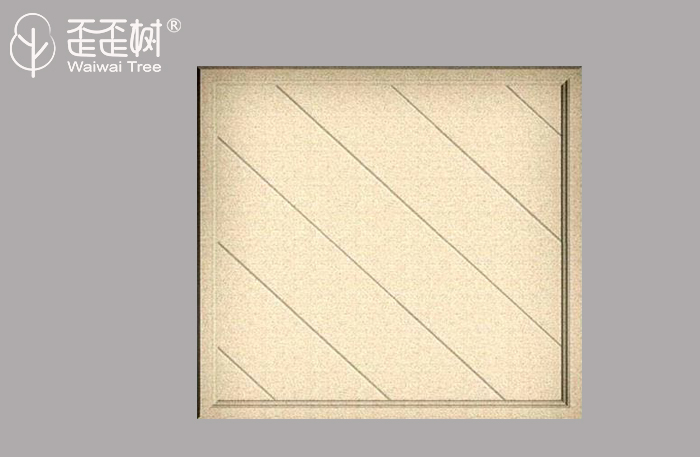

BMC, SMC, GRP, GFK Ceiling

Aobang composite ceiling is divided into: BMC ceiling, SMC ceiling, GRP ceiling, GFK Ceiling.

The ceiling materials have been developed for more than ten years, and the technology is constantly being updated. The PVC ceiling is not resistant to high temperature, and it is easy to deform in a hot environment. The plastic steel plate is improved from the second generation of ceiling material PVC, which has the advantages of lower price, good thermal insulation and sound insulation, rich color and easy making and installation.

However, according to the supervision and inspection results of the plastic sheet market by the Supervisory Office, the quality pass rate of plastic steel products on the market is only 40%, and the phenomenon of “water injection” in bending strength, coating thickness and alkali resistance is serious. Moreover, the plastic steel sheet has low strength, is easily twisted, is not environmentally friendly, has poor weather resistance, and releases toxic gases when burned. The physical properties of the composite material aggregate ceiling are very stable, and will not be deformed even if the water is long time.

The composite ceiling is an excellent material for the ceiling and naturalization board in terms of strength and rigidity. The ceiling uses BMC,SMC,GRP,GFK bulk molding compound as a completely environmentally friendly material, and its advantages are numerous, as follows:

Beautiful, moisture-proof, easy to clean, excellent flame retardant effect, high strength, long life, high environmental protection, easy installation, moisture-proof and waterproof, heat insulation, corrosion resistance, tight connection, oxidation resistance, anti-aging, no deformation, high strength, Light and tough, with natural texture and wooden texture, a variety of colors, natural and beautiful, with a variety of specifications, size, shape, thickness, the same processing properties as logs, no pollution, recycling, no cracks, no expansion, no deformation, no maintenance, no mold, anti-corrosion, anti-insect, anti-termite, energy saving. What is important is the low material cost of BMC,SMC,GRP,GFK molding compound, making it a cost-effective ceiling material than such as steel-plastic panels, aluminum gussets, and aluminum alloys.

The visual effect is soft, feels good, high strength, flame retardant, fireproof, and has strong weather resistance.

Excellent insulation and heat insulation performance, which overcomes the poor thermal insulation performance of traditional ceilings.

Good water resistance, no corrosion, no deformation, no fading and no other undesirable phenomena in a humid environment.

Excellent sound absorption, it is a good sound insulation material, suitable for public places such as medium and high-grade office buildings and large conference halls.

Aobang technology limitedhas a technical team engaged in many years of production and R&Dof bmc composite, and has the industry-leading expertise and technical level. We are dedicated to meeting the needs of our customers and highlighting the value that is given to our customers.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| BMC, SMC, GRP, GFK Wall Panel | Composite wall panel is a new generation of high performance building partition board made of a variety of building materials instead of traditiona... | |

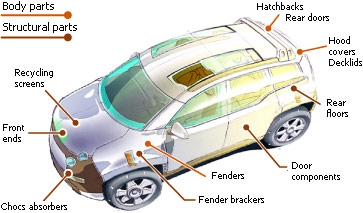

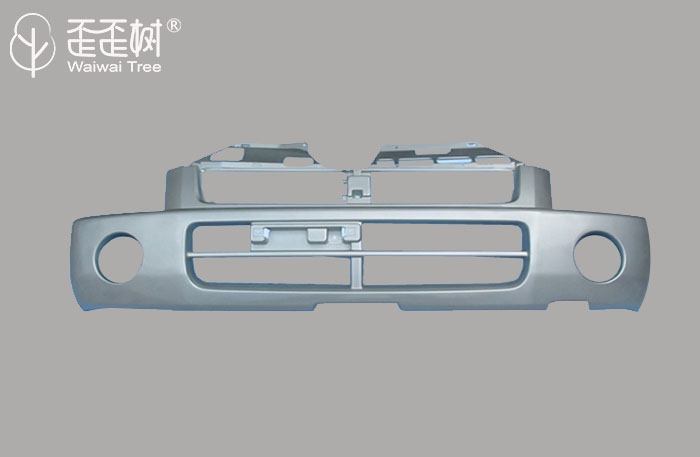

| SMC Automotive Molding, Car Mould | SMC AutomotiveMolding, Car Mould Cars, buses, trucks, transport and special vehicles • Weight: Parts made from sheet molding compound (... | |

| SMC Auto Parts | SMC Auto Parts Description Auto parts made from sheet molding compound (SMC) are typically 25-35% lighter than steel parts and aluminum products... | |

| BMC/SMC Motor | BMC/SMC Motor Description BMC plastic edging motor replaces traditional iron and aluminum, reduces the process, seals more, and has higher safety ... | |

| BMC, SMC, GRP, GFK Roof Tiles | Aobang composite roofing tiles is divided into: BMC roofing tiles, SMC roofing tiles, GRP roof tiles, GFK roofing tiles. Due to the excellent prop... |

Похожие товары

| Вакуумный насос с трехфазным асинхронным двигателем | Продавец: Taizhou Sulin Electromechanical Co., Ltd. | Трехфазный асинхронный двигатель для вакуумных насосов — это специализированный двигатель, ... | |

| IndustrialFlex Worm Gear Motor | Продавец: Ruian Zhanpeng Machinery Co., Ltd | IndustrialFlex Worm Gear Motoris built to support equipment requiring smooth motion transmission ... | |

| TorqueBalance High Precision Gear Reducer Motor | Продавец: Ruian Zhanpeng Machinery Co., Ltd | TorqueBalance High Precision Gear Reducer Motorprovides controlled speed output and flexible redu... | |

| High Precision Gear Reducer Motor | Продавец: Ruian Zhanpeng Machinery Co., Ltd | The High Precision Gear Reducer Motoris an advanced power transmission solution that combines a h... | |

| Philips TTF Motor 9498 396 00197 | Продавец: KF-SMT Technology Co., Ltd | Part Name: PHILIPS TTF MOTORPart NO: 9498 396 00197 Delivery 1-5working days ... |