ALLOY STEEL PIPES ASTM A 335 STEEL PIPES Chrome Moly Pipes

Petrol Steel Co.,Ltd is a professional alloy steel pipes astm a 335 steel pipes chrome moly pipes manufacturer supplying you with customized alloy steel pipes astm a 335 steel pipes chrome moly pipes, welcome to wholesale products from our factory.

ALLOY STEEL PIPES ASTM A 335 STEEL PIPES Chrome Moly Pipes

We are leading manufacturer and stockiest of ASTM A 335 STEEL PIPES ALLOY STEEL PIPES in China.

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES Specifications:

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES Size: OD: 14-914mm WT: 1-35 mm.

Forging/hot rolling/ extrusion of steel.

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P11 Forging: Shafts with flanks/pipes/tubes/slugs/donuts/cubes/other shapes

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P11 Finished goods condition: hot forging/hot rolling + annealing/normalizing + tempering/quenching + tempering/any conditions based on the customer's requirement

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P11 Surface conditions: scaled (hot working finish)/ground/rough machining/fine machining/based on the customer's requirement

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P11 Furnaces for metallurgical processing: electrode arc + LF/VD/VOD/ESR/Vacuum consumable electrode.

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P11 Ultrasonic inspection: 100% ultrasonic inspection for any inperfections or based on the customer's requirement.

UTS according to SEP 1921 C/c,D/d,E/e;A388 or GB/T 6402

Excellent service for all kinds of industries, with advantages of technologies, equipment and price.

We serve you with our honesty, integrity, and professionalism.

Mechanical Tests Specified of ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P12

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P12

Transverse or Longitudinal Tension Test and Flattening Test, Hardness Test, or Bend Test

For material heat treated in a batch-type furnace, tests shall be made on 5% of the pipe from each treated lot. For small lots, at least one pipe shall be tested.

For material heat treated by the continuous process, tests shall be made on a sufficient number of pipe to constitute 5% of the lot, but in no case less than 2 pipe.

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P12

Notes for Hardness Test:

P91 shall not have a hardness not exceeding 250 HB/265 HV [25HRC].

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P12

Notes for Bend Test:

For pipe whose diameter exceeds NPS 25 and whose diameter to wall thickness ratio is 7.0 or less shall be subjected to the bend test instead of the flattening test.

Other pipe whose diameter equals or exceeds NPS 10 may be given the bend test in place of the flattening test subject to the approval of the purchaser.

The bend test specimens shall be bent at room temperature through 180 without cracking on the outside of the bent portion.

The inside diameter of the bend shall be 1 inch [25 mm].

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P12

Hydrostatic Test

Each length of pipe shall be Hydro tested, at option of manufacture, nondestructive electric testing can be used.

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P22 Specification:

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P22 is ordered to this specification shall be suitable for bending,

flanging (vanstoning), and similar forming operations, and for fusion welding.

Selection will depend upon design, service conditions, mechanical properties,

and high-temperature characteristics.

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P22 equivalent Standards: EN 10216-2, ASTM A213, ASME SA213, GOST 550-75, NBR 5603

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P22 Equivalent Material: T22, 10CrMo910, 10CrMo9-10, 1.7380, 11CrMo9-10, 1.7383

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P22 Manufacture

Pipe may be either hot finished or cold drawn with the finishing heat treatment noted below.

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P22 Heat Treatment

A / N+T

N+T / Q+T

N+T

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P22Chemical Composition:

C, % Mn, % P,% S,% Si,% Cr,% Mo,%

0.05-0.15 0.30-0.60 0.025 max 0.025 max 0.50 max 1.90-2.60 0.87-1.13

ASTM A335/ASME A335 P22 Alloy Pipe Steel Mechanical Properties:

Tensile Strength , MPa Yield Strength, MPa Elongation, %

415 min 205 min 30 min

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P91 Heat Treatment Requirements

P5, P9, P11, and P22

Grade

Heat Treatment Type

Normalizing Temperature Range F [C]

Subcritical Annealing or Tempering Temperature Range F [C]

P5 (b,c)

Full or Isothermal Anneal

Normalize and Temper

*****

1250 [675]

Subcritical Anneal (P5c only)

*****

1325– 1375 [715– 745]

P9

Full or Isothermal Anneal

Normalize and Temper

*****

1250 [675]

P11

Full or Isothermal Anneal

Normalize and Temper

*****

1200 [650]

P22

Full or Isothermal Anneal

Normalize and Temper

*****

1250 [675]

P91

Normalize and Temper

1900-1975 [1040– 1080]

1350-1470 [730– 800]

Quench and Temper

1900-1975 [1040– 1080]

1350-1470 [730– 800]

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P91 Chemical Requirements

Grade

P-5

P-9

P-11

P-22

P-91

P-91 shall also include the following:

Element

UNS Designation

K41545

S50400

K11597

K21590

K91560

Carbon

0.15 max

0.15 max

0.05– 0.15

0.05– 0.15

0.08– 0.12

V at 0.18– 0.25

Manganese

0.30– 0.60

0.30– 0.60

0.30– 0.60

0.30– 0.60

0.30– 0.60

N at 0.030– 0.070

Phosphorous, max

0.025

0.025

0.025

0.025

0.020

Ni at 0.40 max

Sulfur, max

0.025

0.025

0.025

0.025

0.010

Al at 0.02 max

Silicon

0.50 max

0.25– 1.00

0.50– 1.00

0.50 max

0.20 -0.50

Cb at 0.06– 0.10

Chromium

4.00– 6.00

8.00– 10.00

1.00– 1.50

1.90– 2.60

8.00– 9.50

Ti at 0.01 max

Molybdenum

0.45 -0.65

0.90– 1.10

0.44– 0.65

0.87– 1.13

0.85– 1.05

Zr at 0.01 max

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P91 Tensile Requirements

Seamless

P-5

P-9

P-11

P-22

P-91

P91 shall not have a hardness not exceeding 250 HB/265 HV [25HRC].

Tensile Strength, min., psi

ksi

60

60

60

60

85

MPa

415

415

415

415

585

Yield Strength, min., psi

ksi

30

30

30

30

60

MPa

205

205

205

205

415

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P91 Permissible Variation in Wall Thickness

NPS [DN] Designator

Tolerance, % from Specified

Over

Under

1/8 to 2 1/2 [6 to 65] incl., all t/D ratios

20.0%

12.5%

Above 2 1/2 [65], t/D < or = 5%

22.5%

12.5%

Above 2 1/2 [65], t/D > 5%

15.0%

12.5%

(t = Specified Wall Thickness; D = Specified Outside Diameter)

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P91 Elongation Requirements

Calculated Minimum Elongation Values

Elongation in 2 in. or 50 mm, min %

Wall Thickness

P5, P9, P11, P22

P91

in.

mm

Longitudinal

Transverse

Longitudinal

5/16 (0.312)

8

30

20

20

9/32 (0.281)

7.2

28

19

19

1/4 (0.250)

6.4

27

18

18

7/32 (0.219)

5.6

26

17

3/16 (0.188)

4.8

24

16

5/32 (0.156)

4

22

15

7/8 (0.125)

3.2

21

14

3/32 (0.094)

2.4

20

13

1/18 (0.062)

1.6

18

12

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P91 Permissible Variations in Outside Diameter

Outside Diameter at any point shall not vary from standard specified more than:

NPS [DN] Designator

Over

Under

in.

mm

in.

mm

1/8 to 1 1/2 [6 to 40], incl.

1/64 (0.015)

0.40

1/64 (0.015)

0.40

Over 1 1/2 to 4 [40 to 100], incl.

1/32 (0.031)

0.79

1/32 (0.031)

0.79

Over 4 to 8 [100 to 200], incl.

1/16 (0.062)

1.59

1/32 (0.031)

0.79

Over 8 to 12 [200 to 300], incl.

3/32 (0.093)

2.38

1/32 (0.031)

0.79

Over 12 [300]

+/- 1% of the specified outside diameter

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P1 with IBR Certified (ASTM A335 / A335M - 11 Standard Specification for Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service)

This specification covers nominal wall and minimum wall seamless ferritic alloy-steel pipe intended for high temperature service. Pipe ordered to this specification shall be suitable for bending, flanges (vanishing), and similar forming operations, and for fusion welding.

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P1 Name: ASTM SA335 Alloy Steel Tubes for boilers, superheaters and heat exchangers

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P2 Specifications

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P2 Size Range: 1/2" NB to 36" NB

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P2 Thickness Range: SCH 40, SCH 80, SCH 160, SCH XS, SCH XXS, All Schedules

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P2 End Connections for Line Pipes: Plain, Bevel, Screwed, Threaded

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P2 Type: Seamless / ERW / Welded / Fabricated / CDW

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P2 Form: Round Pipes/Tubes, Square Pipes/Tubes, Rectangular Pipe/Tubes, Coiled Tubes, "U" Shape, Pan Cake Coils, Hydraulic Tubes

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P2 Length: Single Random, Double Random & Required Length, Custom Size – 12 Meter lengths

Mechanical properties of ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P5

Technological properties of ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P5

Hardness and heat treatment specification of ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P5

Annealing hardness

HBS

Cold pull hardness

HBS

Preheating temperature

℃

Quenching temperature

℃

Holding time

min

Hardening medium

Temper temperature

℃

After tempering hardness

≥HRC

salt-bath furnace

controlled atmosphere furnace

235

262

788

1191

1204

5~15

air cooling

522

60

Steel plate/Sheet

thickness / mm

σb

MPa

σs

≥/MPa

δ

Samples from the standard for 50 mm (2 in)

180 ° of cold bending test

longitudinal

horizontal

Hot-rolled/Cold rolling:5 - 150

520

415

16~18

2a

3.5a

Note:

(1) listed in the table apex diameter (d), to steel thickness (a) multiples said.

(2) in the ASTM A6 standard specified scope can meet any additional conditions.

(3) from the standard for 50 mm (2 in). ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P5 Mechanical properties ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P5 Mechanische Eigenschaften ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P5 Caracteristiques mecaniques ReH Minimum yield strength / Mindestwert der oberen Streckgrenze / Limite d’elasticite minimale Rm Tensile strength / Zugfestigkeit / Resistance a la traction A Minimum elongation / Mindestwert der Bruchdehnung / Allongement minimal J Notch impact test / Kerbschlagbiegeversuch / Essai de flexion par choc

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P9 Chemical composition % of the ladle analysis

C(%)

Si(%)

Mn(%)

P(%)

S(%)

Cr(%)

Mo(%)

Max 0.15

0.25-1.00

0.30-0.60

Max 0.025

Max 0.025

8.00-10.00

0.90-1.10

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P9 Round bar:

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P9 Diameter : 1mm-2000mm

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P9 Square bar:

Size: 50mm * 50mm-600mm *600mm

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P9 Plate steel/flat bar:

Size: Thickness: 0.1mm-800mm Width: 10mm to 1500mm

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P9 Tube/pipe:

Size: OD: 6-219mm WT: 1-35 mm.

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P9 Cold-rolled sheet: Thickness: 2-5mm Width:1000mm Length: 2000mm

ASTM A 335 STEEL PIPES ALLOY STEEL PIPES P9 Hot-rolled sheet: Thickness:6-80mm Width: 210-610mm

The types of ASTM A 335 STEEL PIPES ALLOY STEEL PIPES

12Cr1MoV

JIS G3458 STPA23

JIS G3462 STBA23

A335 P12

A369 FP12

A199 T11

A213 T11

15CrMo

JISG3458 STPA22

JISG3462 STBA22

A335 P12

A369 FP12

A213 T12

12Cr1MoV

JIS G3458 STPA23

JIS G3462 STBA23

A335 P12

A369 FP12

A199 T11

A213 T11

15CrMo

JISG3458 STPA22

JISG3462 STBA22

A335 P12

A369 FP12

A213 T12

GB 16Mo

JIS G3458 STPA12

JIS G3462 STBA12

JIS G3462 STBA13

ASTM A369 FP1

ASTM A A250-T1

ASTM A209-T1

DIN 17175 1.5414

DIN 17175 15Mo3

GB 12CrMo

JIS G3462 STBA20

GB Cr5Mo

JIS G3458 STBA25

JIS G3462 STPA26

JIS G3458 STBA26

JIS G3462 STPA25

ASTM A389-FP5

DIN17175 12CrMo195 1.7362

ONE OF THE KIND, MILLIONS OF CHOICES

SUPERIOR QUALITY

PROMPT DELIVERY

FAVORABLE FEEDBACK

ALL AVAILABLE IN PESCO

SELECT PESCO, YOU WILL BE RIGHT

For more info and price of ASTM A 335 STEEL PIPES ALLOY STEEL PIPES, please send us inquiry and you will have quick reply soon.

Другие товары поставщика

|

|

|

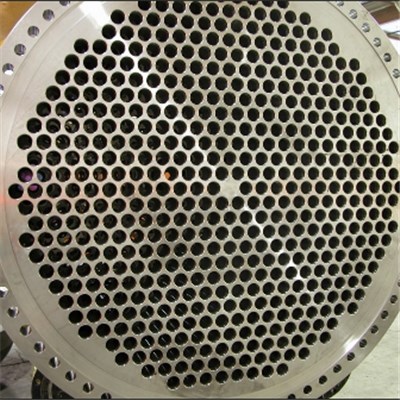

We are leading manufacturer and stockist of Stainless TubeSheet in China.Diameter of Stainless TubeSheet: Dia.500mm ~ Dia.3500mmThe Process of Stai... |

|

|

|

We are leading manufacturer and stockist of BS 2S120 in China.Non-Corrosion Resisting Steel 2S120 BS 2S120 Technical Data SheetBS 2S120 Chemical Co... |

|

|

|

Performance Data• Capacity: 10~2,Website: L/min• Inlet Pressure: -0.07~0.7Mpa; Discharge Pressure: 0.1~10.0Mpa• Medium Temperature: ≤280℃• Medium V... |

|

|

|

We are leading manufacturer and stockist of Orifice Flange in China.Designed for flow metering systems. Orifice Flange with bolts and jack screws a... |

|

|

|

We are leading manufacturer and stockist of API 5L X70 STEEL PIPES in China.API 5L X70 STEEL PIPES specification CHEMICAL COMPOSITI... |

Все товары поставщика

Похожие товары