Sheet Metal Cabinets

Sheet metal has the characteristics of lightweight, high strength, electrical conductivity (can be used for electromagnetic shielding), low cost, and large-scale mass production performance. Sheet metal cabinet fabricationis widely used in the fields of electronics, telecommunications, automotive industry, medical equipment and so on. For example, in computer cases, mobile s, and MP3s, custom sheet metal cabinetsplays an important part.

With the increasing use of sheet metal, the design of sheet metal cabinet has become an important part of product industry development. Mechanical engineers must be proficient in the design skills of sheet metal parts.

Common sheet metal cabinets include power cabinets, network cabinets, server cabinets, and outdoor cabinets.

As one of the leading sheet metal cabinets manufacturers, HSJ Fabrication provides custom sheet metal cabinets.

Sheet Metal Cabinets WhatsApp

Electronic part

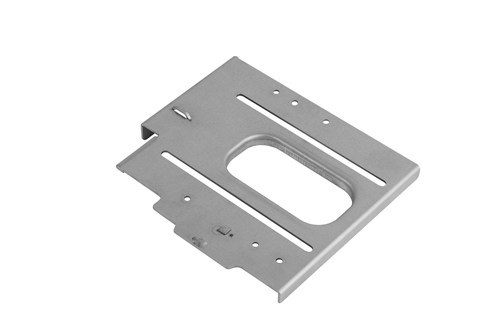

OEM Laser Cutting custom computer case sheet metal part,computer enclosure Computer host shell,electronic sheet metal parts.

Thickness:0.1mm—20mm

Tolerance: + / - 0.02 mm - 0.1 mm

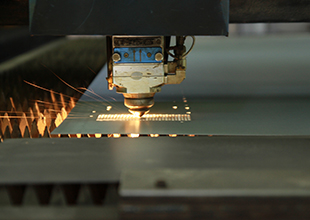

Equipment: HSG(HS-G3015A) laser machine

Production capacity: pcs

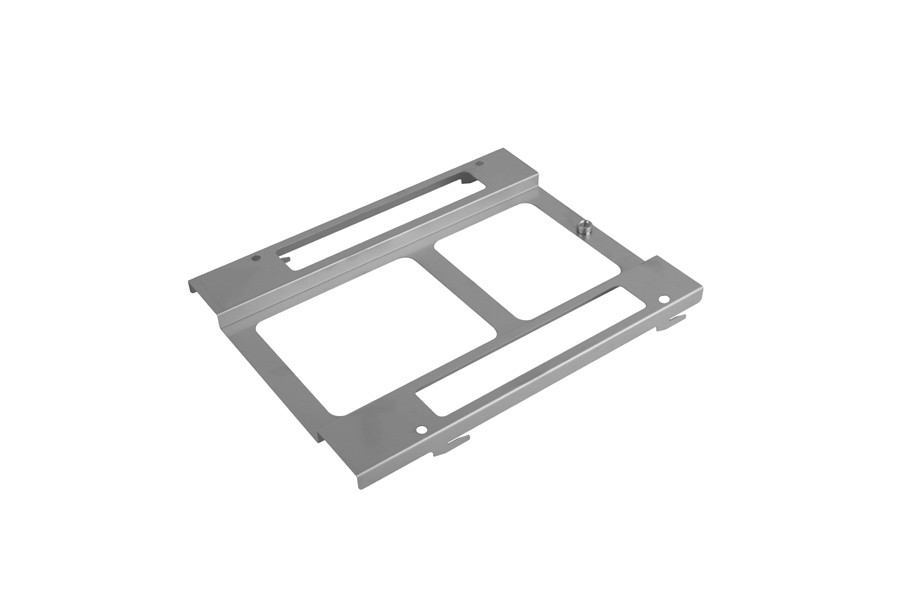

Electronic part

Thickness:0.1mm—20mm

Tolerance: + / - 0.02 mm - 0.1 mm

Equipment: HSG(HS-G3015A) laser machine,bending machine

Production capacity: pcs

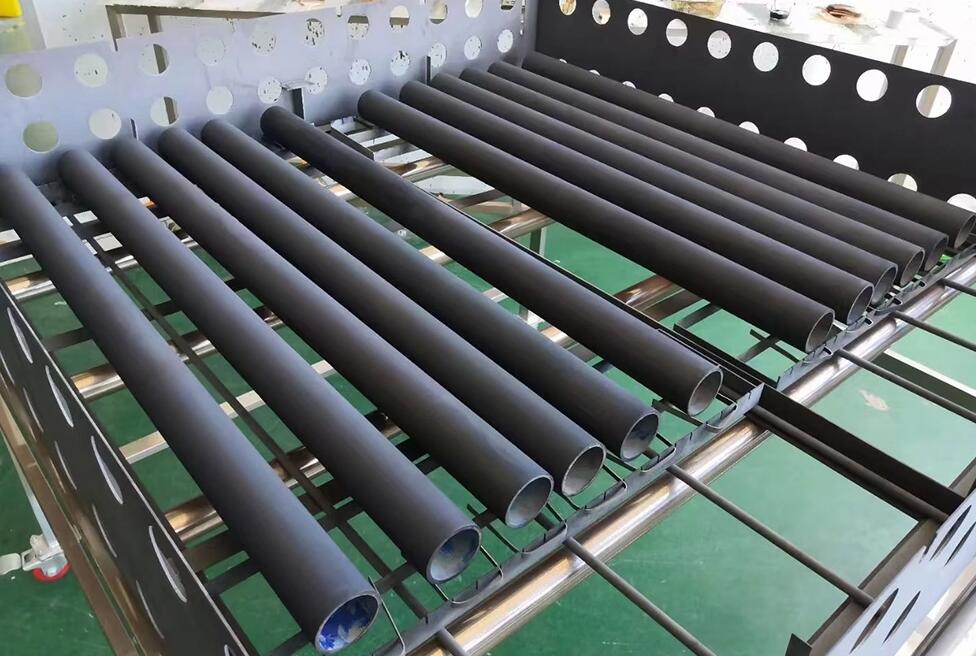

Sheet Metal Cabinets Materials

Materials for sheet metal cabinet fabrication: SGCC galvanized plate, SECC electrolytic plate, SUS stainless steel (model 201 304 316, etc.), SPCC iron plate, white copper, red copper, AL aluminum plate (model 5052 6061, etc.), SPTE, spring steel, manganese steel

Sheet Metal Cabinets Custom Solutions

Sending the drawing or your demand to us. Let us know your products’ details, as one of a leading metal cabinet fabricators, we could offer the sample for you.

If you are looking for a reliable laser cutting manufacturer,HSJ can be your best choice. We have our own designer team and professional service will get back to you. Please contact us in any time.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| SHEET METAL STAMPING | Sheet metal stamping (also known as metal pressing and forming) is the process of placing flat sheet metal in either blank or coil form into a stam... | |

| Custom Aluminum Parts | Custom Parts Fabrication Material : aluminum (AS PICTURES) Process : CNC machine + deburrs Type : Broaching, Drilling, Etching / Chemical... | |

| Metal Fabrication | Shenzhen HSJ Metal Fabrication Co., Ltd. has rich experience in providing high-quality sheet metal fabrication products based on customers requirem... | |

| Bending Perforated Aluminium Sheet | Materials: stainless steel(we also can customize other material such as as: metal/steel/Aluminium and so on) Service: OEM ODM Surface Treatment: Z... | |

| Laser Carving Plate | Laser Carving Plate Produce material: aluminum Process: laser carving Tolerance: +-0.1mm Thickness: Packing: packed with carton an... |

Похожие товары

| Rare Earth | Продавец: UrbanMines Tech. Limited | Cerium(Ce);Erbium(Er);Dysprosium(Dy);Europium(Eu) ;Gadolinium(Gd) ;Holmium(Ho);Lanthanum(La) ;Lut... | |

| Titanium Capillary Tube | Продавец: Baoji City Changsheng Titanium Co.,Ltd | Normally titanium tubes with an outside diameter of less than 3mm as capillaries. The main raw ma... | |

| Titanium Bolt | Продавец: Baoji City Changsheng Titanium Co.,Ltd | Titanium Bolts Wholesale Titanium bolts have the characteristics of low density, high specific s... | |

| Titanium Basket | Продавец: Baoji City Changsheng Titanium Co.,Ltd | Titanium mesh basketis light in weight, has strong corrosion resistance, and has a layer of oxide... | |

| Titanium Anode & Electrode | Продавец: Baoji City Changsheng Titanium Co.,Ltd | The procedure entails brushing, sintering, and electroplating. The coating's components and quant... |