Modular Oil Refinery

Catalog of Modular Oil Refinery

|

Mode |

Capacity (BPD) |

Power (Kw/d) |

Fabrication Period (month) |

Area (Acre) |

Skid Number |

Weight (Ton) |

|

MR10 |

1000 |

150 |

5 |

1 |

5 |

120 |

|

MR30 |

3000 |

200 |

5 |

2 |

7 |

160 |

|

MR50 |

5000 |

275 |

6 |

2 |

8 |

200 |

|

MR100 |

10000 |

350 |

6 |

3 |

11 |

375 |

EPC Scope of Work for Modular Oil Refinery

|

EPC Scope of Work |

||||

|

Item |

By PCC |

By End-user |

||

|

1 |

Feasibility Study |

Engineering |

√ |

|

|

2 |

Basic Design |

√ |

||

|

3 |

Detail Design |

√ |

||

|

4 |

Budgeted Deliverables |

√ |

||

|

5 |

local government approval and supervision |

√ |

||

|

6 |

Purchase Requisitions |

√ |

||

|

7 |

Parsed MTO |

Procurement |

√ |

|

|

8 |

Purchase Order |

√ |

||

|

9 |

Transportation & Logistics |

√ |

||

|

10 |

Release to Construction |

√ |

||

|

11 |

Contracts |

√ |

||

|

12 |

General Const.Plan |

Construction |

√ |

|

|

13 |

Civil work |

√ |

||

|

14 |

Piping |

√ |

||

|

15 |

System Turn-over |

√ |

||

|

16 |

Start-up & Commissioning |

√ |

||

|

17 |

Performance Run |

√ |

||

|

18 |

Turn-Over to end-user |

√ |

||

|

OSBL & ISBL Scope of Work |

||||

|

Item |

By PCC |

By End-user |

||

|

1 |

10000 BPD CDU+VDU |

Inside Battery Limits |

√ |

|

|

2 |

Tank Farm |

Outside Battery Limits |

√ |

|

|

3 |

Water Supply and Drainage System |

√ |

||

|

4 |

Power Supply and Telecommunication System |

√ |

||

|

5 |

System Pipelines |

√ |

||

|

6 |

Central Control Room |

√ |

||

|

7 |

Wharf and Berth |

√ |

||

|

8 |

Vehicle Load-Unload Facility |

√ |

||

|

9 |

Flare System |

√ |

||

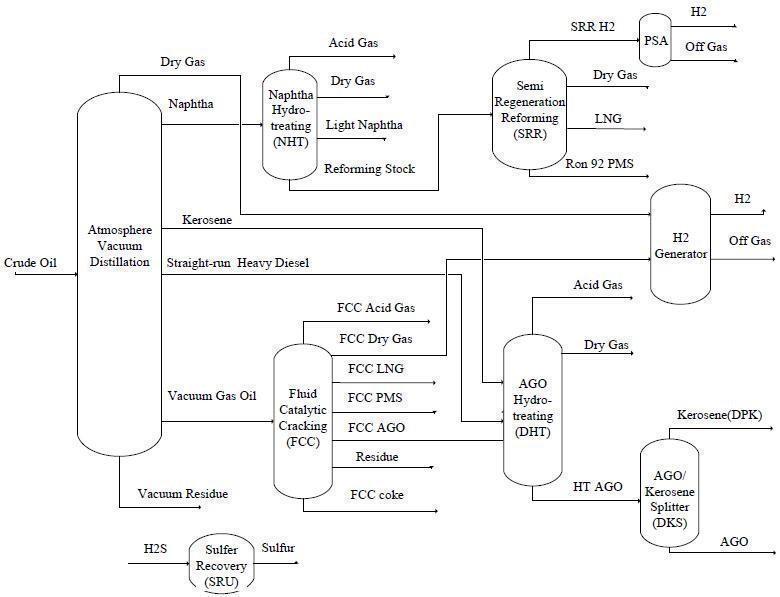

Process Flow Diagram of Modular Oil Refinery

Take one of Nigeria crude oil with API Gravity 36.25 and mercaptan sulfur 1.3ppm for example.

Process Philosophy of Modular Oil Refinery

Feedstock will be separated into naphtha, kerosene, straight-run heavy diesel, atmospheric residue oil by ADU. Naphtha from ADU is sent to NHT unit, in which reforming stock is main product. Reforming stock is rectified by Semi Regeneration Reforming (SRR). PMS and LNG are sent to respective tanks as products. And hydrogen can be regenerated by PSA.

Atmospheric residue oil is sent to vacuum distillation unit (VDU), vacuum gas oil can be produced. Then it is sent to FCC. The FCC dry gas is sent to Hydrogen Generator with dry gas from ADU. FCC AGO together with kerosene and diesel from ADU are sent to DHT unit. HT AGO will be produced and sent to AGO/Kerosene splitter where DPK and AGO will be produced. DPK and AGO will be sent to respective tanks as products.

The sulfur will go into the dry gas, LPG, gasoline and FCC fume and so on. And there is sour waste water produced in the processing. The sour gas and sour waste water should be purified to meet the standard of environmental protection. The stripped sour waste water will be used as injection water of the electric desalting. The stripped sour gas will be burnt and changed into SO2, then discharged to the atmosphere.

We are oil refinery factoryand crude oil refineries for sale,if you want to find floating oil refinery,oil refinery engineeringor oil refining plant,we are your best choice,we also provide mini refinery feasibility study pdf.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| MODULAR REFINERY | PCC's Modular Refineries are designed and fabricated in our manufacturing base located in Tianjin, China. As the name implies, all equipment is con... | |

| Modular Acetone Solvent Recovery Plant | Project Name Modular Acetone Solvent Recovery Plant Location Jinan, China Time November 2015 Client Pharmaceutical company ... | |

| MODULAR REFINERY | PCC's Modular Refineries are designed and fabricated in our manufacturing base located in Tianjin, China. As the name implies, all equipment is con... | |

| Diesel Hydrotreating Unit | Hydrotreating process(DHT): uses hydrogen to desulfurization unitthe naphtha fraction from the crude oil distillation or other units within the ref... | |

| Heli-Pak, Distillation Column Experimental Packing | HeliPakis a particle type packing and can be "poured" into any laboratory or pilot scale column. Easily removed for replacement or cleaning. Speci... |

Похожие товары

| MTFH63-211GRB-11A36 11Pin PH1.27mm Vertical Dual Row Female Header | Продавец: MTCONN ELECTRONICS CO.,LTD | This dual-row vertical surface-mount (SMT) gold-plated headerfeatures a 1.27mm pitch design with ... | |

| HM Pumex Grinding Machine | Продавец: Shenzhen JuYongNeng Technology Co., Ltd | HM Pumex Grinding Machine Product Description Name TSP HM3/6-75 S/Z... | |

| Dynamic Axial Compression Column | Продавец: Xinsheng Pharmaceutical Instrument Co., Ltd | A DAC column,or Dynamic Axial Compression column,is a self-packingcolumn used for separation in l... | |

| China manufacturer Turbine bolt electric heater ZJ-17-T4 for power generation | Продавец: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "China manufacturer Turbine bolt electric heater ZJ-17-T4 for power generation Is YOYIK for the u... | |

| China factory Turbine bolt electric heater ZJ-20-16 for power station Deyang | Продавец: DONGFANG YOYIK (DEYANG) ENGNIEERING CO; LTD | "China factory Turbine bolt electric heater ZJ-20-16 for power station Deyang YOYIK have power pl... |