Bright Annealed Tubes

Bright Annealed Tubes Description

The traditional annealing approach is performed in a so referred to as open furnace, where the atmospheric oxygen reasons scaling of the heat treated materials, which makes the surface rough. HUASHANG STEEL has developed a one of a kind bright annealing process, the heat treatment is carried out in a so-called clsoed furnace. The warmth handled materials is covered by means of an inter-fuel atmosphere, which ensures the oxygen cant enter the furance or come in to contact with the substances and react to shape scale on or tarnish the materials. The surfaceend is clean, bright and precision, which is a top-notch beginning point for similarly system, like electro-polishing and mechanical polishing.Especially for the tube with size greater than 12 meters, the ordinary pickling tube is very hard to clean the internal surface, however, with the bright annealing method, ourbright annealed stainless steel tubingis much cleaner, smoother on both inner and outer surface. We,pipe fittings manufacturers in chinause bright annealing method, the temperature of furnace can reach greater than 1350℃, and the tolerance for the putting and real temperature can be controlled Within ±2℃, which is not possible for the regular annealing To ensure the quality, all tubes are done 100% PMI, 100% Hydraulic test, 100% inner cleaned by sponge, 100% dimension test, and 100% surface test.

What is more, our quality of precision drawn tubing is same to precision rolling but has more advantage on price? We are using the advanced cold drawn technology from Japan and Korean, making the close dimension controls Huashang steel tubing used for instrument tubing, chromatography tubing, hydraulic tubing, high-pressure tubing, cleaned tubing, multi-core tubing. Type of tubes is welded tubing and seamless tubing.

Straight Tubes Bright Annealed Tube Advantages

1. Superior Surface Finish2. Better Mechanical Property

3. More Precise Dimension

Bright Annealed Tubes Sizes

welded tubing size rangeOD: 0.19mm--44.5mm, T.W: 0.08mm--3.81mm

Length: CUT TO LENGTH

The seamless straight tubing & bright annealed tubing sizes:

| OD(mm)*T.W (mm) |

| 4.76×0.51/4.76×0.71/4.76×0.89/4.76×1.24 |

| 6×1/6×1.5 |

| 6.35×0.51/6.35×0.71/6.35×0.89/6.35×1.24/6.35×1.65 |

| 7.94×0.71/7.94×0.89/7.94×1.24/7.94×1.65 |

| 9.53×0.71/9.53×0.89/9.53×1.24/9.53×1.65 |

| 10×1/10×1.5/10×2 |

| 12×1/12×1.5 |

| 12.7×0.71/12.7×0.89/12.7*1.24/12.7×1.65 |

| 15.88×0.71/15.88×0.89/15.88×1.24/15.88×1.65/15.88×2.11 |

| 16×1/16×1.5/16×2 |

| 19.05×1/19.05×1.24/19.05×1.65/19.05×2.11 |

| 25.4×1.24/25.4×1.65/25.4×2.11/25.4×2.54 |

| 31.8×1.24/31.8×1.65/31.8×2.11/31.8×2.54 |

| 38.1×1.24/38.1×1.65/38.1×2.11/38.1×2.54/38.1×3.05 |

Bright Annealed Tubes Materials

Austenitic Stainless Steel:TP304, TP304L, TP304H, TP304LN, TP316/TP316L, TP316H, TP316Ti, TP316LN, TP321, TP321H,TP317, TP317L, TP347, TP347H, TP310S, TP310H, TP904L, 254Mo. S30432, S31042, N08367

Duplex & Super Duplex Steel: S31500, S32101, S32003, S32304, S31803, S32205, S32750, S32760

Nickel Alloy Steel:

N06600, N06601, N06625, N07718, N08800, N08825, N10276, N04400, N05500, N02200, N02201, N08028, N08810, N08811, N08020, N10624, N10629, N10675

Bright Annealed Tubes Standard

ASTM A789, ASME SA789, EN10216-5, ASTM B163, ASTM B167, ASME SB163, ASME SB167, ASTM B668, ASME SB668, ASTM A269, ASME SB677, ASTM A213, ASME SA213, ASME SA269, ASMT A270, ASTM B622, ASTM B516

Heat Treatment: Bright Annealed

NDT: Eddy Current or Hydraulic test or UT

Chemical Composition of Nickel Alloy, Duplex steel & Austenitic Steel

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo | Ti | N | Cu | Fe | Al | Co | Zr | Nb | Tu | Va |

| Max | Max | Max | Max | Max | Max | Max | Max | Max | Max | |||||||||

| Nickel Alloy | ||||||||||||||||||

| Inconel 600/No6600/2.4816 | 0.15 | 0.5 | 1 | 0.015 | 14-17 | ≧72 | 0.5 | 6.0-10.0 | ||||||||||

| Inconel 600/No6601/2.4851 | 0.1 | 0.5 | 1.5 | 0.015 | 21-25 | 58-63 | 1 | 1.0-1.7 | ||||||||||

| Inconel 690/No6690 | 0.05 | 0.5 | 0.5 | 0.015 | 27-31 | 58 | 0.5 | 7.0-11.0 | ||||||||||

| Inconel 625/No6625/2.4856 | 0.1 | 0.5 | 0.5 | 0.015 | 0.015 | 20-23 | ≧58 | 8.0-10.0 | ≦0.4 | 5 | ≦0.4 | 3.15-4.15 | ||||||

| Inconel 718/No7718/2.4668 | 0.08 | 0.35 | 0.35 | 0.015 | 0.015 | 17-21 | 50-55 | 2.8-3.3 | 0.65-1.15 | 0.006 | 0.3 | Remainder | 0.2-0.8 | 4.75-5.5 | ||||

| Incoloy 800/No8800/1.4876 | 0.1 | 1 | 1.5 | 0.015 | 19-23 | 30-35 | 0.15-0.6 | 0.75 | ≧39.5 | 0.15-0.6 | ||||||||

| Incoloy 800H/No8810/1.4958 | 0.05-0.1 | 1 | 1.5 | 0.015 | 19-23 | 30-35 | 0.6-1.2 | 0.75 | ≧39.5 | 0.15-0.6 | 1 | |||||||

| Incoloy 825/No8825/2.4858 | 0.05 | 0.5 | 1 | 0.03 | 19.5-23.5 | 38-46 | 2.5-3.5 | 1.5-3 | ≧22 | 0.2 | ||||||||

| C-276/No10276/2.4819 | 0.01 | 0.08 | 1 | 0.04 | 0.03 | 14.5-16.5 | Balance | 15.0-17.0 | 4.0-7.0 | 2.5 | 3-4.5 | 0.35 | ||||||

| Monel 400/No4400/2.4360 | 0.3 | 0.5 | 2 | 0.024 | ≧63 | 28-34 | 2.5 | |||||||||||

| Monel K-500/No5500 | 0.18 | 0.5 | 1.5 | 0.01 | 63 | 0.35-0.85 | 27-33 | 2 | 2.3-3.15 | |||||||||

| Alloy 20/No8020/2.4660 | 0.07 | 1 | 2 | 0.045 | 0.035 | 19-21 | 32-38 | 2.0-3.0 | 3.0-4.0 | Balance | 8C-1 | |||||||

| Alloy 28/No8028 | 0.03 | 1 | 2.5 | 0.03 | 0.03 | 26-28 | 30-34 | 3.0-4.0 | 0.6-1.4 | Remainder | ||||||||

| Duplex Steel | ||||||||||||||||||

| S31803/1.4462 | 0.03 | 1 | 2 | 0.03 | 0.02 | 21-23 | 4.5-6.5 | 2.5-3.5 | 0.08-0.2 | |||||||||

| S32205/1.4462 | 0.03 | 1 | 2 | 0.03 | 0.02 | 22-23 | 4.5-6.5 | 3.0-3.5 | 0.14-0.2 | |||||||||

| S32750/1.4410 | 0.03 | 0.8 | 1.2 | 0.035 | 0.02 | 24-26 | 6.0-8.0 | 3.0-3.5 | 0.24-0.32 | 0.5 | ||||||||

| S32760/1.4501 | 0.05 | 1 | 1 | 0.03 | 0.01 | 24-26 | 6.0-8.0 | 3.0-4.0 | 0.2-0.3 | 0.5-1.0 | ||||||||

| Austenitic | ||||||||||||||||||

| 304/1.4301 | 0.08 | 1 | 2 | 0.045 | 0.03 | 18-20 | 8-10.5 | |||||||||||

| 304L/1.4307 | 0.035 | 1 | 2 | 0.045 | 0.03 | 18-20 | 8.0-12.0 | |||||||||||

| 304H/1.4948 | 0.04-0.1 | 1 | 2 | 0.045 | 0.03 | 18-20 | 8.0-11.0 | |||||||||||

| 316/1.4401 | 0.08 | 1 | 2 | 0.045 | 0.03 | 16-18 | 11.0-14.0 | 2.0-3.0 | ||||||||||

| 316L/1.4404 | 0.035 | 1 | 2 | 0.045 | 0.03 | 16-18 | 10.0-14.0 | 2.0-3.0 | ||||||||||

| 316H/1.4919 | 0.04-0.1 | 1 | 2 | 0.045 | 0.03 | 16-18 | 10.0-14.0 | 2.0-3.0 | 0.1 | |||||||||

| 316Ti/1.4571 | 0.08 | 1 | 2 | 0.045 | 0.03 | 16-18 | 10.0-14.0 | 2.0-3.0 | 0.7>5x(C+N) | |||||||||

| 321/1.4541 | 0.08 | 1 | 2 | 0.045 | 0.03 | 17-19 | 9.0-12.0 | 0.7>5x(C+N) | ||||||||||

| 321H/1.4878 | 0.04-0.1 | 1 | 2 | 0.045 | 0.03 | 17-19 | 9.0-12.0 | H | ||||||||||

| 317/1.4449 | 0.08 | 1 | 2 | 0.045 | 0.03 | 18-20 | 11.0-14.0 | 3.0-4.0 | ||||||||||

| 317L/1.4438 | 0.035 | 1 | 2 | 0.045 | 0.03 | 18-20 | 11.0-15.0 | 3.0-4.0 | ||||||||||

| 347/1.4550 | 0.08 | 1 | 2 | 0.045 | 0.03 | 17-19 | 9.0-12.0 | |||||||||||

| 347H/1.4912 | 0.04-0.1 | 1 | 2 | 0.045 | 0.03 | 17-19 | 9.0-13.0 | |||||||||||

| 310S/1.4845 | 0.08 | 1 | 2 | 0.045 | 0.03 | 24-26 | 19.0-22.0 | 0.11 | ||||||||||

| 310H/1.4845 | 0.04-0.1 | 1 | 2 | 0.045 | 0.03 | 24-26 | 19.0-22.0 | |||||||||||

| N08904(904L)/1.4539 | 0.02 | 1 | 2 | 0.045 | 0.03 | 19-23 | 23.0-28.0 | 4.0-5.0 | 0.1 | 1.0-2.0 | ||||||||

| S31254(254Mo)/1.4547 | 0.02 | 0.8 | 1 | 0.03 | 0.01 | 19.5-20.5 | 17.5-18.5 | 6.0-6.5 | 0.18-0.22 | 0.5-1.0 | ||||||||

Bright Annealed Tubes Specification/Technical Data

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Stainless Steel Capillary Tubes | Product description Stainless Steel Capillary TubeDescription: Whether you need to exchange device tubing as a section of your troubleshooting or... | |

| Stainless Steel Capillary Tubes | Product description Stainless Steel Capillary Tube Description: Whether you need to exchange device tubing as a section of your troubleshooting or ... | |

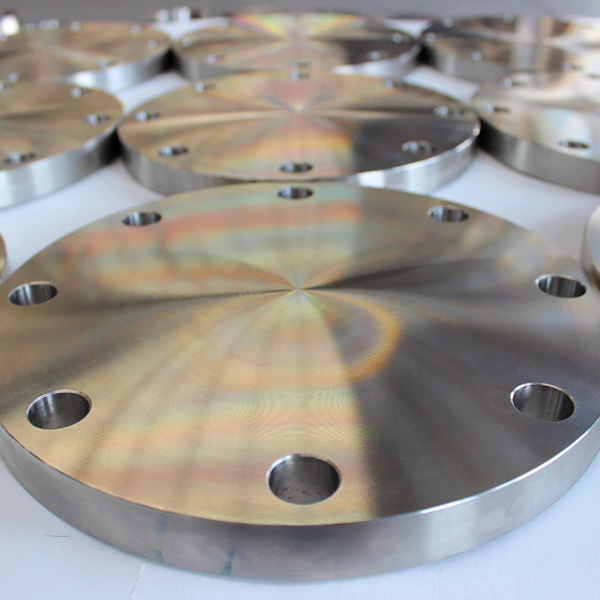

| Blind Flanges | Product description Steel blind flangeis also called blind board, and its proper name is flange cover. It is a flange without holes in the middle ... | |

| Equal Tee | Product description We are manufacturer, supplier, and exporter of equal tees, which are also understood as straight tees, these equal tees have a ... | |

| Bright Annealed Tubes | Product description Bright Annealed Tubes Description Bright annealed stainless steel tubeis a kind of high precision steel tube material after fin... |

Похожие товары

| Бесшовная труба | Продавец: Eastern Steel Manufacturing Co.,Ltd | Seamless pipe is a long steel strip with a hollow cross-section and no seams around it. &zw... | |

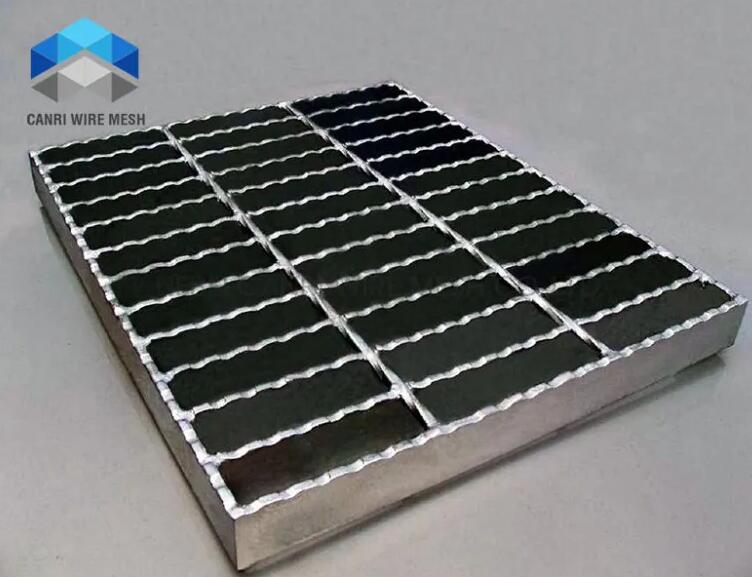

| Galvanized Steel Grating for Drainage | Продавец: Hebei Canri wire Mesh co.,Ltd | Galvanized Steel Grating for Drainage Steel gratingfor drainage, also known as galvanised draina... | |

| Floor Grating | Продавец: Hebei Canri wire Mesh co.,Ltd | Floor Grating Floor grating, also known as open grid flooringor bar grating, is a type of structu... | |

| Serrated Bar Steel Grating | Продавец: Hebei Canri wire Mesh co.,Ltd | Serrated Bar Steel Grating Steel bar gratinghas two surface type: serrated surface and smooth su... | |

| Stainless Steel Grating | Продавец: Hebei Canri wire Mesh co.,Ltd | Stainless Steel Grating Stainless steel gratinghas been the standard industrial foot walk produc... |