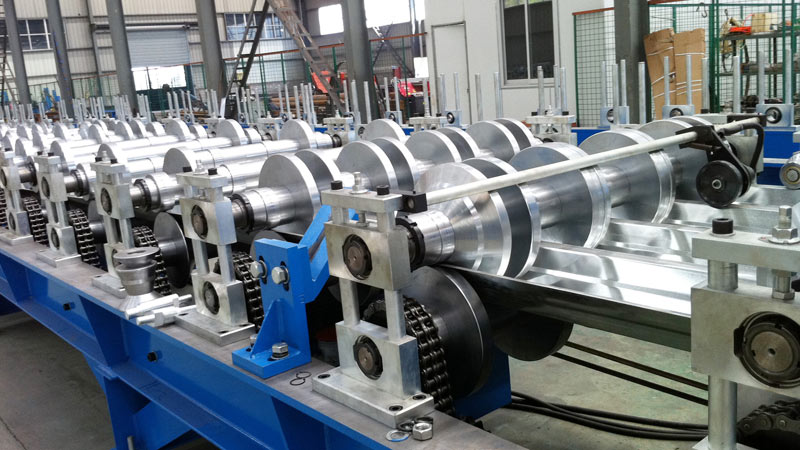

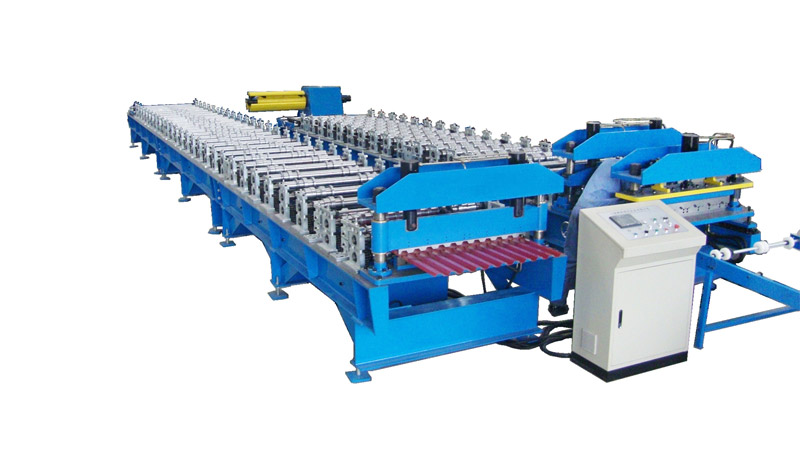

HIGH SPEED TUBE MILL LINE

High Speed Tube MillLine is used to produce tube diameter between φ4mm to φ50mm. The top working speed of this tube mill linecan reach as high as 120m/min to 130m/min.

Main Technical Parameters of HighSpeedTubeMill (For reference only, will be as requests):

A: suitable strip coils

Alloy Steel Coil; API5L X42-X80

(For reference only, will be as requests)

Length: 6m-12m

Length tolerance:+/-3mm

Production speed: 120-130m/min

Direction: Left to right or right to left from operator's side(as requests by customer)

Capacity: 10,000 ton/year-15, 000 ton/year

Electricity input power: 50kW-65kW

Foundation: 40m–50m (length) x 3.8m-4m (width)

Weight: About 30ton–300ton.

Operator: 6-8 people (as size requests)

High-Speed Tube Mill Line Technical parameters

|

Model |

Round pipe |

Square pipe |

Thickness |

Speed |

|

mm |

mm |

mm |

m/min |

|

|

RFT-12 |

Ф4-Ф12 |

120-130 |

||

|

RFT-16 |

Ф6-Ф16 |

120-130 |

||

|

RFT-20 |

Ф8-Ф20 |

6x6-15x15 |

120-130 |

|

|

RFT-25 |

Ф10-Ф25 |

7x7-19x19 |

120-130 |

|

|

RFT-32 |

Ф12-Ф32 |

9x9-25x25 |

120-130 |

|

|

RFT-50 |

Ф20-Ф50 |

15x15-39x39 |

120-130 |

High-Speed Tube Mill Line Applications

Finished Tubes by High-Speed Tube Mill

Specifications of High-Speed Tube Mill

|

Machine Condition |

Fully New, A Grade quality |

|

Size |

As requests |

|

Power Supply |

220V/380V/415V/460V/480V, 50/60Hz, 3P (as requests) |

|

Equipment Weight |

About 30ton-300ton |

|

Dimension |

40m–400m (length) x 3.8m-40m (width) |

|

LOADING SIZE |

Normally need 4-30 x 40' containers |

|

Equipment Color |

normally Blue/Green/White, or as requests |

|

Place of Origin |

Zhejiang, China (Mainland) |

|

Packing |

Standard and careful export packing |

For more informationabout how to operate roll forming machine, please feel free to contact us!

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| High Speed Metal Deck Roll Former | Fully automatic, our high speed rollformer is designed with a Cassette-type platform and a quick-change machine base so as to better achieve multi-... | |

| Roofing Tile/Glazed Tile Making Machine | Features and Advantages ofRoofing Tile/glazed tile making machine Roofing Tile & Glazed Tile Making Machine,is for continuously roll forming an... | |

| Double Layer Roll Forming Machine | Double layer roll forming machine, also called double deck roll forming machine. To meet the requirements for roll forming two different profiles i... | |

| AG PANEL ROLL FORMER | AG panel roll formeris a machine used in the manufacturing process of metal roofing panels. The machine is used to shape flat metal sheets into a c... | |

| Roof Panel Roll Forming Machine | This metal cladding roll forming machineis used to roll-form metal roof panels and metal wall panels. The roll forming line usually includes metal ... |

Похожие товары

| Cable Pulling Sock | Продавец: 00000 | Cable Pulling Sock CABLE PULLING SOCK: The is the most ideal tool designed for electrical a... | |

| Side Dragging Cable Grip | Продавец: 00000 | Side Dragging Cable Grip Side Dragging Cable Grip SGA/MGT/SK/MK is also called cable sock w... | |

| Cable Pulling Grips TG MG TGM TGK | Продавец: 00000 | Cable Pulling Grips TG MG TGM TGK Head Traction Cable Grip TG/MG/TGM/TGK Cable grips are a ... | |

| Cable Grip Supplier | Продавец: 00000 | Cable Grip Supplier Cable Grip: A Reliable Solution for Safe Cable Pulling and Handling A... | |

| Cable Roller Manufacturer | Продавец: 00000 | Cable Roller Manufacturer Cable Roller: Essential Equipment for Safe and Efficient Cable Ins... |