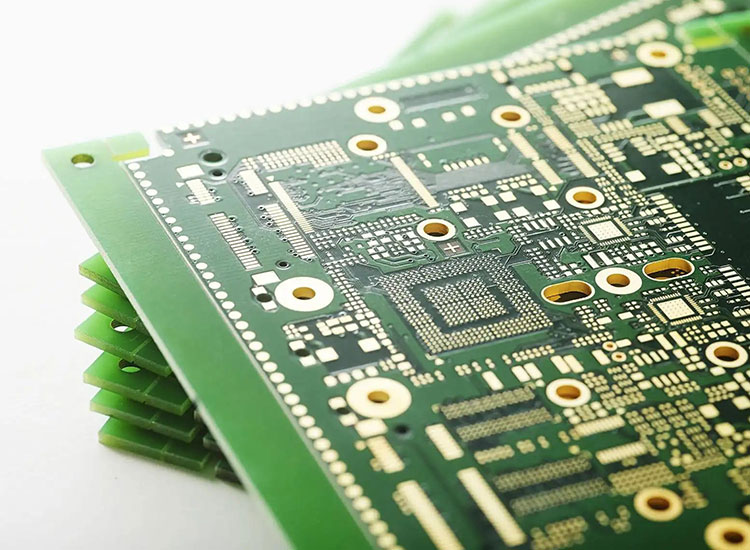

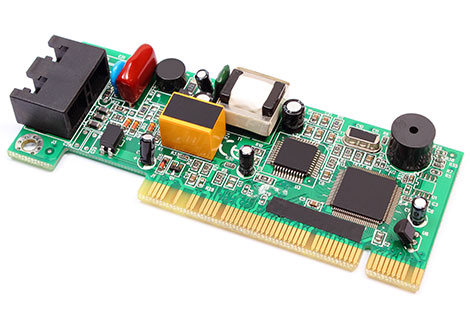

PCB Surface

PCB surface finishinclude: PCB surfacefinish is a coating between a component and a bare board PCB. It is applied for two basic reasons: to ensure solderability, and to protect exposed copper circuitry. As there are many types of surface finishes, selecting the right one is no easy task, especially as surface mounts have become more complex and regulations such as RoHS and WEEE have changed industry standards.

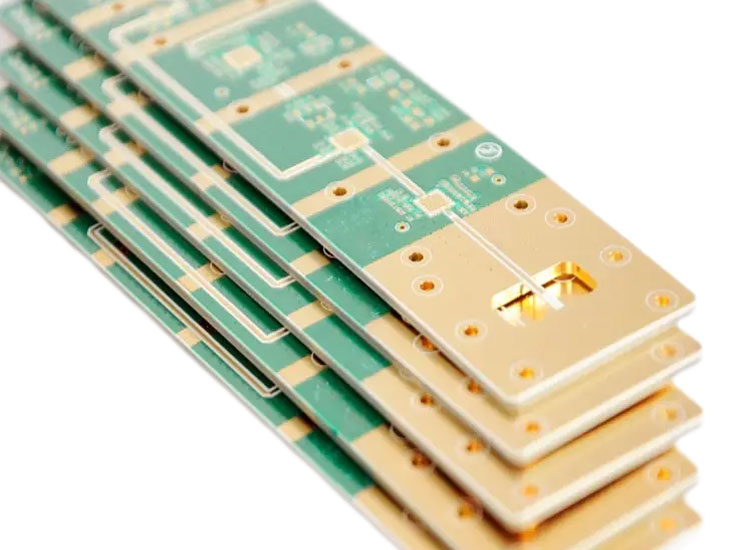

Recently, the common surface pcbtreatment technologies which GreensTone may use when manufacturing PCBs are HASL(hot air solder leveling), organic coating (OSP), electroless nickel/gold, immersion silver, immersion gold, etc.

The solder mask is mainly Liquid UV Photo-imageable Ink with green, red, black, yellow, white, matt black/green, bule, gray, etc. green should be the most commonly used one. The suggested soldermask clearance in GERBER is 2-4 mils.

The silkscreen layer is the top layer of the printed circuit boardand serves as a reference indicator for placing components on the PCB. The graphics and text on PCB, a circuit board is usually printed with a permanent non-conductive epoxy ink. The color is typically white. Screen printing is used to specify useful information on the PCB board, which can help users during the assembly. It is used to mark component values, part numbers, test points, polarity, etc.

PCB Surface Features

PCBfinishcomparison of cost and solderability

Actual solderability: Electroplating nickel gold> HASL > OSP > ENIG >Immersion silver >Immersion tin

Cost: Electroplating nickel gold > ENIG > Immersion silver> Immersion tin > HASL > OSP.

The functions of the solder mask layer on the PCB board

Preventing short circuit from bridge connection in the soldering process

Preventing the physical breakage of a conductor circuit

Prevent short circuit between conductive lines and solder joints when proceeding reflow soldering, wave soldering, and manual welding

Preventing the copper layer from oxidation

Its high Insulating brings the possibility to the high density of PCB boards

Here are three main ways to add silkscreen coating on a PCB

Manual screen-printing: This is a process that can be used when line widths are greater than 7 mm and the registration tolerance is 5 mm.

Liquid Photo Imaging (LPI): This process provides more accuracy and legibility over manual screening and is used when line widths are greater than 4 mm

Direct Legend Printing (DLP): This is the most accurate way of adding a silkscreen, however, it is very expensive.

PCB Surface Manufacturing Introduction

|

HASL (hot air solder leveling)/HASL lead Free |

HASL/HASL lead free is the process of coating tin-lead/ tin-lead free solder on the surface of PCB so that it forms a layer of both anti-copper oxidation and good weld ability of the coating. |

|

Organic Coating (OSP) |

OSP is a chemical process to build a layer of organic skin film on the clean bare copper surface, it helps anti-oxidation,and moisture resistance, to protect the copper surface from vulcanization or oxidation, etc. In simply words,OSP acts as a barrier between copper and air. |

|

ENIG (Electroless Nickel/Immersion Gold) |

ENIG is a thick nickel gold alloy with good electrical properties on the copper surface,acts as a rust barrier to protect PCB for a long time, which can be useful and achieve excellent electrical performance in the long term use of PCB. |

|

Immersion Silver |

Silver impregnation does not put heavy coat on PCB, which provides good electrical properties and maintains good solder ability when exposed to humidity ,heat,and pollution, |

|

Immersion Tin |

With adding organic additives to the tin layer, the tin layer structure is granular, which overcomes the tin whisker problems and has excellent thermal stability and solder ability. |

As one of contract electronics manufacturing companies, we will do our best to meet all the needs of customers.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Sheet Metal Fabrication | Sheet metal is used to make objects of various thicknesses, from very thin sheet metal to sheet metal with a thickness greater than 6mm. Sheet meta... | |

| FR4 PCB | What is FR4? FR4is the name of a type of epoxy glazing material. fr stands for flame retardant. 4 refers to the factors that differentiate it fr... | |

| DELIVER MOLDING MECHANICAL DESIGNS SYSTEMATICALLY | GreensTone mechanical design engineers will work with your team to design and test the best solutions for your products. Gain full access to our sp... | |

| Heavy Copper PCB | Heavy Copper PCB PCBs with a copper thickness of more than 70um are called thick copper PCBs, sometimes also called thick copper PCBs. Copper thic... | |

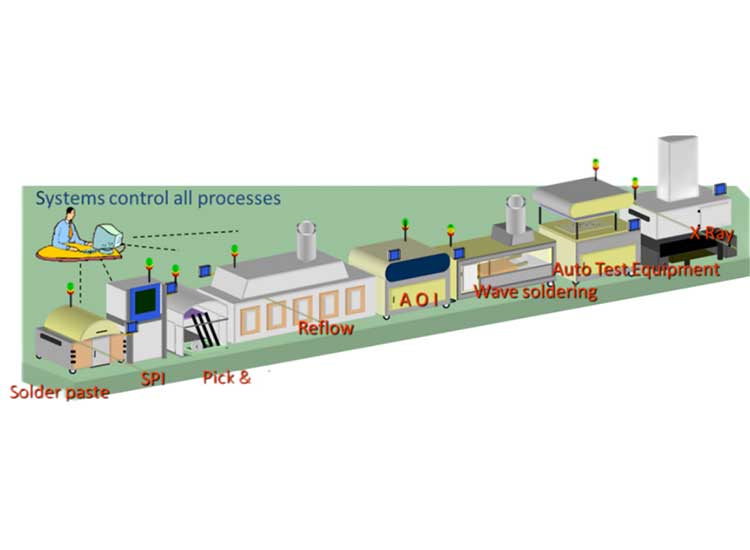

| SMT PCB Assembly | SMT PCB Assembly As SMT assembly supplier, GreensTone SMT production runs with automated SMT production processes, including single or double-si... |

Похожие товары

| PCB Surface | Продавец: GreensTone (Shenzhen) Electronics Co., Limited | PCB surfacefinish include: PCB plating finishesis a coating between a component and a bare board ... | |

| PCB Components Sourcing | Продавец: GreensTone (Shenzhen) Electronics Co., Limited | GreensTone Electronics employs a dedicated, parts sourcing and procurement team to manage the log... | |

| PCB Capability | Продавец: GreensTone (Shenzhen) Electronics Co., Limited | GreensTone has successfully served customers with pcb manufacturing capabilitiesservice in commun... | |

| PCB Assembly Service | Продавец: GreensTone (Shenzhen) Electronics Co., Limited | GreensTone specializes in the pcba pcb assembly, including: Circuit board assembly Surface moun... | |

| High-TG PCB | Продавец: GreensTone (Shenzhen) Electronics Co., Limited | Glass Transition Temperature is referred to as Tg, and FR4 is a designation for a particular type... |