Scrap Baller

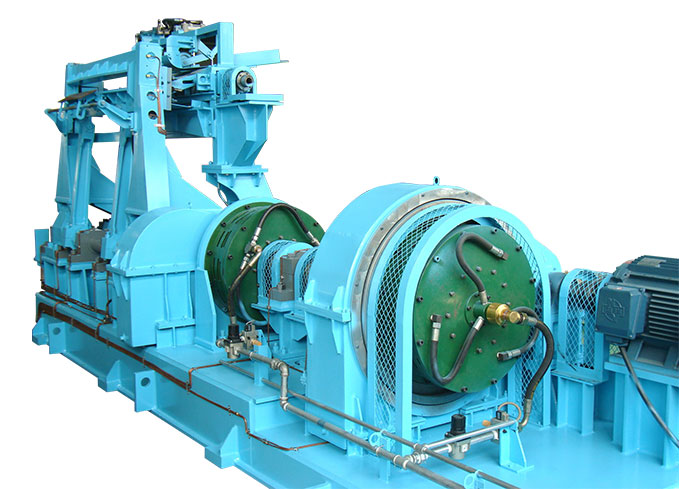

The scrap balleris an excellent choice for us to dispose of waste materials. It rolls the cut edges into a ball and recycles them, and sorts the cut edges in a simple way. The scrap baller provided by BOYA adopts a unique modular design, and its processing performance and control accuracy have reached a high level.

Application Scope of Scrap Baller

|

Material |

Strip Thickness |

Scrap Width |

Trimming Speed |

|

|

Carbon steel, stainless steel, copper and copper alloys, aluminum and aluminum alloys |

4-50mm |

≤700MPa |

≤300m/min |

Structure Advantage of Scrap Baller

Bridle scrap baller adopts mandrel and swing frame, guide the scrap from chute of the side trimmer winding into coil. Pit not required.

Tension scrap baller is applicable for thicker material, high strength, convenience to winding.

Non-tension scrap baller adopts mandrel and follow up frame to pull scrap edge out of pit and winding, no need to stop the unit for guiding the scrap edge, saving production time and meeting the requirements of continuous production.

Tension scrap baller is applicable for thicker and lower strength material.

Main Components for Scrap Baller

Scrap baller consists of 5 parts: Drive part, Snuber roll, Frame Part, Fixed base, transversal shifting device.

Drive part: Drive part is composed of shift base, frequency conversion motor, scroll, frequency conversion motor drives reel rotation to rewind the scrap edge to mandrel, frequency conversion motor installed on the shift base, when need to discharge scrap ball, oil cylinder push the shift base back, take the mandrel out of scrap ball, under the action of gravity and pressure roll, scrap ball will rolling out of the scrap baller and falling into scrap pit.

Snubber roll Part: Snubber roll part consists of oil cylinder and snubber roll, when working snubber roll give pressure to scrap ball by oil cylinder, after finished winding, snubber roll will push the scrap ball out so as to ready for next winding.

Frame Part: Frame part consists of frame, mandrel support base, stop disk, cylinder, etc, mandrel insert into support base by shifting cylinder when winding, to support the cantilever end of mandrel, avoid mandrel swing during winding scrap edge and increase the using life of equipment.

Fixed Base: The fixed base is the foundation of the scrap baller. The box is welded structure with stiffened plate in the middle to improve its rigidity. The post-welding aging treatment will improve its stability.

The shift cylinder is mounted on the base, and the shift base moves left and right under the action of the cylinder to complete the preparation of coiling and uncoiling. The flat cable oil cylinder is fixed on the inlet side of the coiler, and the side guide roller pushes the side scrap edge to move left and right reciprocately, ensure that the scrap edge is wound evenly on the reel.

If you want to know more details of stainless steel coil processing, please visit our website.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Rotary Shear for Annealing and Galvanizing Line | In order to ensure that the tearing surface of the strip is smooth, it is necessary to ensure that the upper and lower knife planes are relatively ... | |

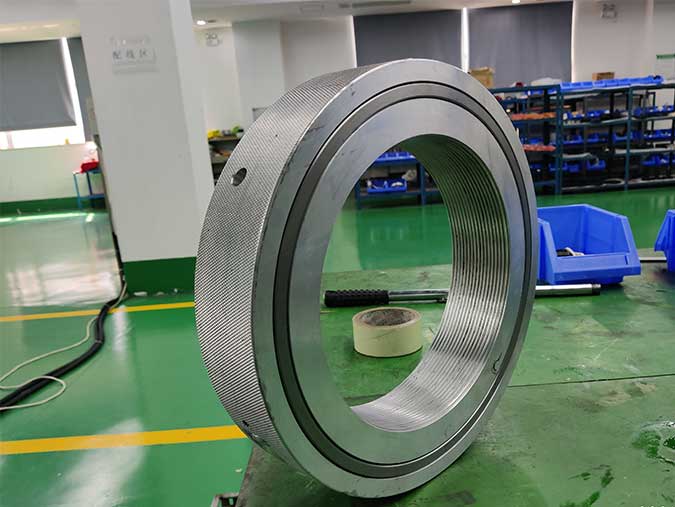

| Hydraulic Nut | Hydraulic nutis a strong fastening component, it is a special nut that integrates a hydraulic device on the nut body and locks the connecting objec... | |

| Cut to Length Machine | BOYA metal cut to length machineis often used in steel rolling production line. In the continuous rolling billet workshop or small section workshop... | |

| Non-standard Bearing | Nonstandard bearings are bearings that do not conform to the outline dimensions stipulated by the national standards, that is, the outline dimensio... | |

| Flat Metal Rolling Leveler | The sheet leveler machineof BOYA is not only rooted in the basic theory of material elastic-plastic deformation but also closely follows the world'... |