high melting point high-temperature strength good heat resistance Material for Die-casting Mold

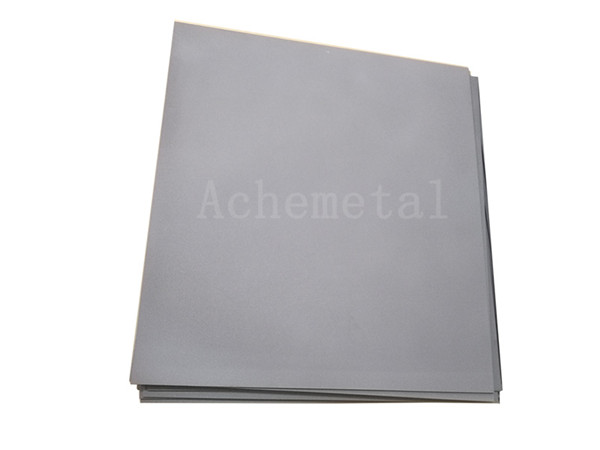

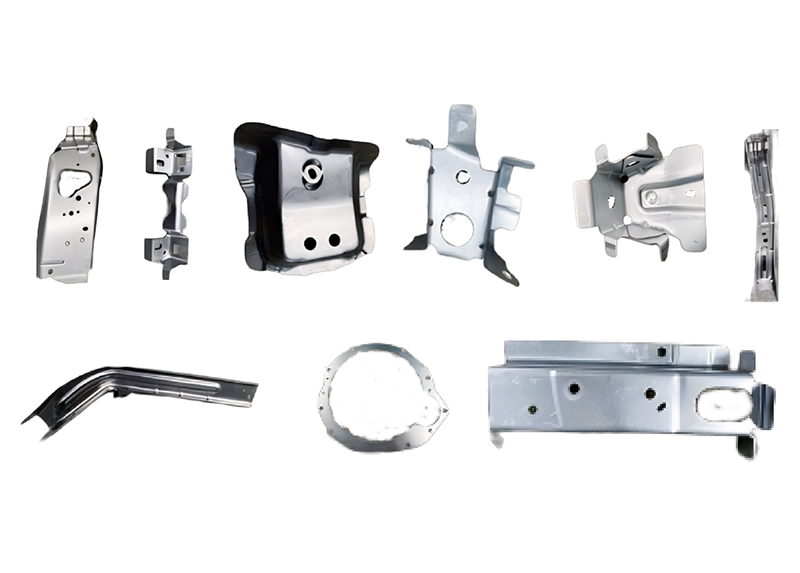

Material-based Alloy for Tungsten-based Alloy and Molybdenum-based Alloy Die-casting Mold In the process of die-casting iron/steel materials, the operating temperature of die-casting mold cavities can reach 1,000℃. After severe oxidation, corrosion and scouring of cavity surfaces, cavities will fail frequently because of severe plastic deformation and netty cracks, and can only die-cast dozens of or hundreds of parts. Therefore, refractory alloys of tungsten, molybdenum, niobium and other alloys with the melting point of more than 2,600℃ can be used for manufacturing cavities of die-casting molds. With the recrystallization temperature of more than 1,000℃, they can operate above this temperature for a long term. Titanium-zirconium-molybdenum alloy represents molybdenum-based alloy while tungsten-molybdenum-nickle-iron represents tungsten-based alloy. These kinds of materials feature extremely high melting point, better high-temperature strength, good heat resistance and corrosion resistance, excellent heat conductivity, thermal fatigue resistance, no bonding with molten metal, good plasticity and convenient molding. It is mainly applied to die-casting molds of copper alloy and iron/steel materials operating at a higher temperature, and can also be used as a thermal extrusion mold and other molds of titanium alloy and heat-resisting steel, with the service life far longer than that of other various kinds of hot work die steel. With outstanding heat conductivity of tungsten-molybdenum-nickle-iron, it also takes advantages in large-batch continuous production of aluminum die castings in the automobile industry.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| high quality Mo-30W Mo-50W Mo-85W Tungsten-molybdenum Alloy | The melting point of tungsten-molybdenum alloy is improved along with the increase of tungsten content. When the tungsten content is increased to 2... | |

| High-specific-gravity higher mechanical property Tungsten Heavy Alloys with 80%~98% tungsten | Tungsten heavy alloys material formed by adding a small amount of Ni, Fe, Cu, Co, Mo, Cr and other elements into tungsten (generally with the conte... | |

| hard high ductility small expansion coefficient high tenacity Tantalum | antalum has an extremely hard texture and the hardness of 6-6.5. Tantalum is a kind of rare metal with steel grey luster, and has the melting point... | |

| good conductor of electricity and heat stable chemical properties Tungsten Carbide | Chemical formula: WC. Black hexagonal crystal, metal luster, high hardness similar to that of diamond, good conductor of electricity and heat. Melt... | |

| self-consumable smelting Tungsten-aluminum flexible materials | Tungsten-aluminum flexible materials self-consumable smelting Tungsten-aluminum flexible materials self-consumable Tungsten-aluminum flexible mater... |