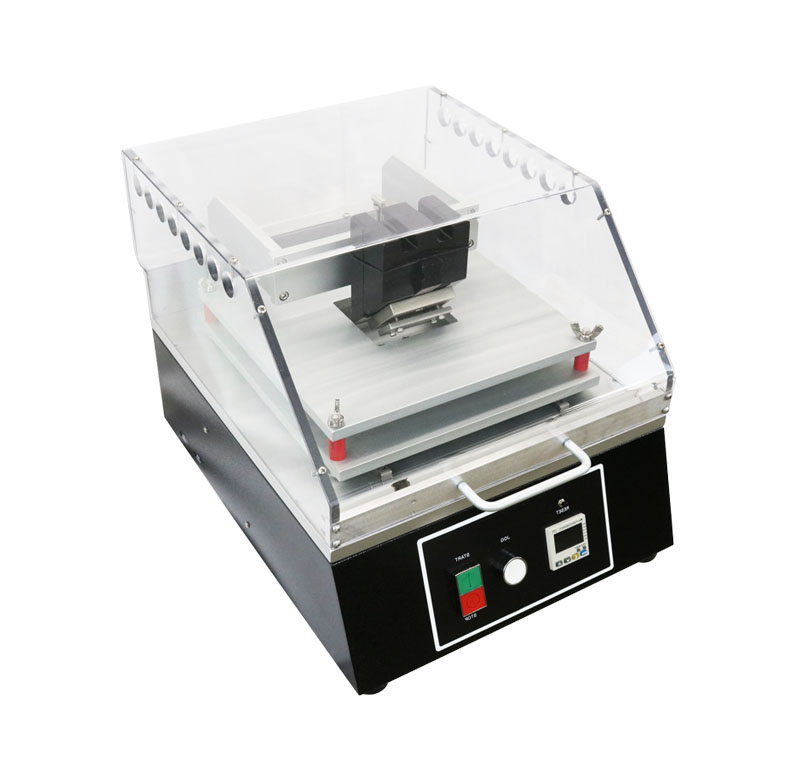

Textile moisture absorption and heat generation performance tester

Application Scope

The textile moisture absorption and heat generation performance tester is a dedicated instrument for testing the moisture absorption and heat generation performance of textiles.

Applicable Standards

1. GB/T 29866 - 2013: This standard stipulates the test method for the moisture absorption and heat generation performance of textiles. It is applicable to various textile products such as fibers, yarns, fabrics, and clothing. Through testing, the ability of textiles to release heat after absorbing moisture can be evaluated.

2. FZ/T 73036 - 2010: This standard is for moisture absorption and heat generation thermal underwear. It includes the weaving requirements of moisture absorption and heat generation materials and the rising temperature value indicators, etc. The textile moisture absorption and heat generation performance tester can be used to test whether the thermal underwear meets the requirements of this standard.

Main Parameters

1. Temperature rise value test range and accuracy: Generally 0 - 100°C, with a resolution of 0.01°C. This parameter is used to measure the temperature increase of textiles after moisture absorption and is a key indicator for evaluating moisture absorption and heat generation performance.

2. Working chamber size: Usually moderate to accommodate textile samples of different sizes. For example, the working chamber size of some models is 350mm×300mm×400mm (width×depth×height).

3. Number of detection channels: Generally, multi-channel detection is adopted, such as four-channel detection, to support the simultaneous testing of multiple samples and improve testing efficiency.

4. Temperature display range: The same as the temperature rise value test range, generally 0 - 100°C.

5. Temperature fluctuation: ≤±0.5°C. This parameter reflects the temperature stability during the test process and has an important impact on the accuracy of the test results.

6. Relative humidity control: Generally 30% - 90% ± 3%. This parameter is used to simulate the ambient humidity conditions of textiles in actual use.

7. Air velocity: Generally 0.3m/s - 0.5m/s (adjustable). Air velocity has a certain impact on the moisture absorption and heat generation performance of textiles, so it needs to be controlled.

8. Test time control: The test time can be set as needed, such as 0min:1s - 99min:59s, with a resolution of 1s. The accuracy of the test time has an important impact on the repeatability of the test results.

9. Other parameters: The configuration and performance of other devices such as sample size, test box material, insulation material, heating/humidifier, refrigeration evaporator, and blower motor will also affect the test results.

Другие товары поставщика

Все товары поставщика

Похожие товары