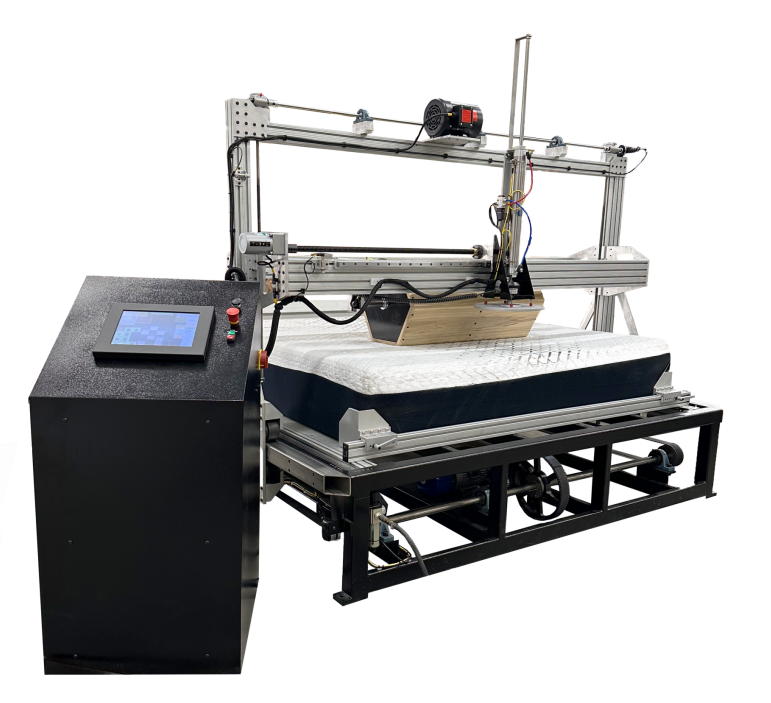

King Size Foam Fatigue Tester

1. Product Function and Application

The King Size Foam Fatigue Tester is a single-station fatigue testing machine designed for evaluating the durability and performance of full-size foam mattresses, including standard King and California King sizes.

It performs fatigue testing in accordance with ASTM D3574 – “Dynamic Fatigue Test by Constant Force Pounding”, simulating long-term, repetitive loading to assess the foam’s resistance to compression and deformation over time.

The system is ideal for mattress manufacturers, foam suppliers, and testing laboratories seeking to ensure product quality, consistency, and compliance with international standards for comfort and durability.

Widely used in the furniture, bedding, foam production, and material testing industries to determine the fatigue resistance, durability, and structural performance of large foam or composite mattress systems under repeated loading.

2. Applicable Test Standards

This tester meets or exceeds the requirements of:

ASTM D3574 — Standard Test Methods for Flexible Cellular Materials (Foam)

Dynamic Fatigue Test by Constant Force Pounding

ISO 2439 — Determination of indentation hardness and deflection

Other related foam compression and fatigue test standards

3. Technical Specifications

| Item | Specification |

|---|---|

| Test Type | Dynamic fatigue test (constant force or constant displacement) |

| Platform Size | Large enough for standard King or California King size mattress |

| Gantry System | Manually positioned X-Y gantry for testing at any location |

| Sample Retainers | Four manually adjustable corner retainers |

| Cylinder Stroke | 12 inches (custom options available) |

| Load Cell Capacity | 500 lbs (fatigue-rated; optional capacities available) |

| Indenter Foot | 250 mm diameter, as specified by ASTM D3574 |

| Cycle Rate | Up to 70 cycles per minute |

| Control System | Touchscreen PLC with selectable test modes |

| Operating Modes | Constant Force / Constant Displacement |

| Power Requirement | 120 VAC |

| Air Requirement | 80 PSI compressed air |

| Customization | Load cell sizes, stroke lengths, cycle speeds, and indenter styles available upon request |

Отправить запрос, связаться с поставщиком

Другие товары поставщика

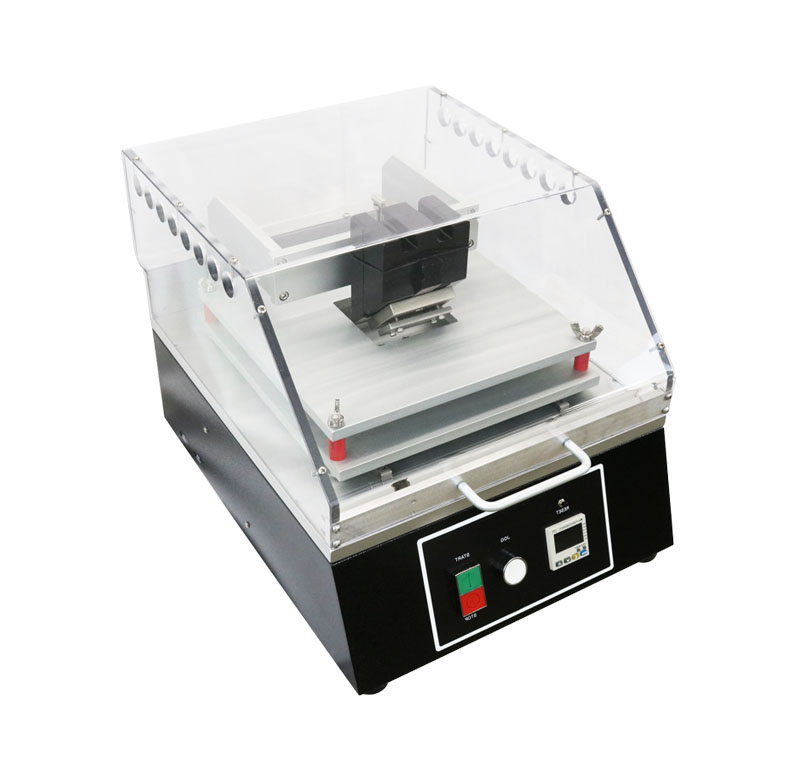

| Fabric Coolness Tester - lab instrument | It is used to measure and evaluate the contact coolness index "q max" (peak heat flux). When the skin comes into contact with fabrics, different am... | |

| Automotive Comfort Air Conditioning Dummy Test System - Test Equipment | Thermal Manikin environment test simulation manikin exchange heat from the external environment by simulating the real physiological mechanism. Com... | |

| Radiant heat drop tester | The tester is used for evaluating the combustion behavior of automotive interior components including dashboards, trim panels, door panels, seat fa... | |

| Light Fastness Tester Si220 | Application: Qinsun si220 is a highly economic material color lightfastness tester that can test up to 250 samples simultaneously. It complies to ... | |

| Conveyor needle detector | It is applicable to detect broken needle and iron matters inmany industries such as garment, textile, shoes and hats,home textiles, quilting etc. ... |

Похожие товары

| Air Intake Filter Test System | Продавец: Standard Groups | The Air Intake Filter Test System is designed for testing industrial air filters and engine air f... | |

| Mattress Spring Fatigue Tester,ASTM D3574 ,how to test mattress for sagging | Продавец: Standard International Group (HK) Limited | The King Size Foam Fatigue Tester is a single-station pneumatic fatigue testing system designed f... | |

| Mattress Rollator,ASTM F1566 ,Mattress Durability Tester,Mattress Fatigue Tester | Продавец: Standard International Group (HK) Limited | The Mattress Rollator is a laboratory durability testing system designed to evaluate the long-ter... | |

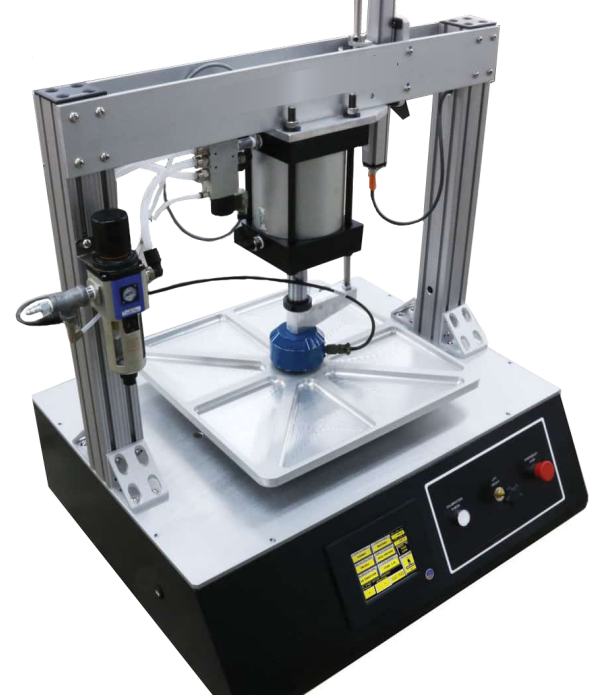

| HD2 Pneumatic Foam Fatigue Tester,ISO 3385,Foam Fatigue Testing Machine | Продавец: Standard International Group (HK) Limited | The HD2 Pneumatic Foam Fatigue Tester is a heavy-duty, single-station laboratory testing machine ... | |

| VW Heel Abrasion Tester,ISO 4649 ,Heel Performance Testing Machine | Продавец: Standard International Group (HK) Limited | The VW Heel Abrasion Tester is designed to evaluate the wear resistance of floor covering materia... |