Degassing Flux

Degassing Flux(SATA-PF-350)

General Description of Degassing Flux (SATA-PF-350)

Practice has proved that the hydrogen is the main cause of the pores in the aluminium alloy, the pores not only reduce the actual cross-sectional area of the casting, but also the source of the crack, so it is important part that removing the hydrogen during the smelting process.

SATA-degassing flux also name aluminum degassing fluxisa kind of traditional high efficiency degassing flux for aluminium and its alloys, it used for removing hydrogen and oxides from the aluminium melting.

Application of Degassing Flux (SATA-PF-350)

Plunge suitable quantity flux to the bottom (100mm from the bottom is better) of the melt, evenly and slowly remove the lunch, make the flux fully react with aluminium molten, stand or stir the molten for 10-15 min, the hydrogen and oxide will be taken out of aluminium molten.

Advantage of Degassing Flux (SATA-PF-350)

Easy operation, There are two options. One is with hexachloroethane in tablet form.and another is in powder form without hexachloroethane

It has excellent performance in refining, degassing and drossing

It can enhance the quality of casting, hydrogen content of aluminium molten can reduce to ≤0.1ml/100gAl, the oxide inclusion(Al2O3) can reduce 20% min, the casting inclusion defect reduce 50%min

Specification of Degassing Flux (SATA-PF-350)

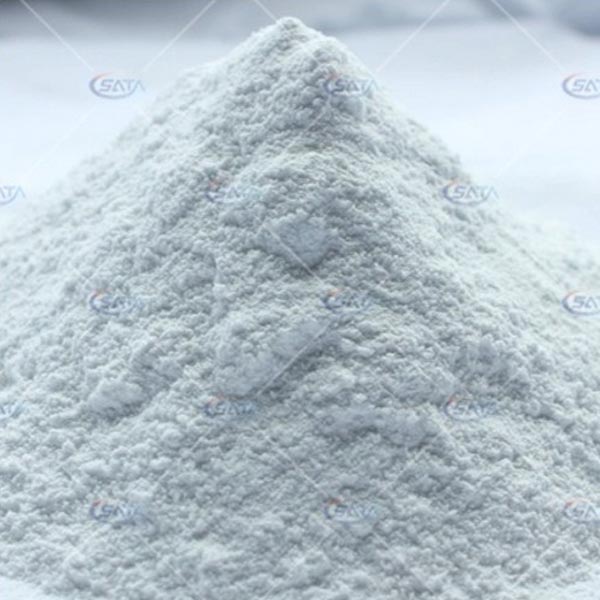

White mixed powder

It is suit for all series alloy except high magnesium alloy,

Dosage: recommended dosage: 3%-5% large melting furnace, 4%-6% for crucible furnace

Working Temperature: 710℃-780℃

Package of Degassing Flux (SATA-PF-350)

Packed in 5kg (PE), 25kg (PP), 1000kg bags or customized.

Stored in dry, well-ventilated place, and avoid direct sunlight, keep sealed before using.

NOTE: This flux has serious hygroscopicity, please use immediately after opening.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Cover Flux | Cover Flux(SATA-PF-340) General Description of Cover Flux (SATA-PF-340) The aluminium melt is extremely easy oxidation and inhale when it is in mel... | |

| Recovering Flux | General description of Recovering Flux Recovering flux is a flux specifically designed for the purpose of treating hot drosses, which is the insuf... | |

| Master Alloy | Master AlloyManufacturer Description of Master Alloy SATA-Master alloys melt at a lower temperature as compared to primary metals. Controlled addit... | |

| Magnesium Chloride Hexahydrate Powder | Magnesium Chloride Hexahydrate Powder General Description of Magnesium Chloride Hexahydrate Powder Chemically, magnesium chloride is represented as... | |

| Potassium Aluminium Fluoride (PAF) | Potassium Aluminium Fluoride (PAF) General Description ofPotassium Aluminium Fluoride(PAF) Molecular Formula: KALF4 /K3ALF6 CAS NO.:14484-69-6 Melt... |

Похожие товары

| Флюс-паста MECHANIC M35 для ремонта материнских плат телефонов | Продавец: Phonefix | Флюс-паста Mechanic M35 10 см3 отличается высокой активностью (98%). Эта высокоэффективная синерг... | |

| Lanrui AS50 Универсальный восстанавливающий крем для устранения точек окисления | Продавец: Phonefix | Описание LANRUI AS50 Универсальный ремонтный крем для удаления пятен окисления на материнских пла... | |

| Флюс-паста Mechanic M35 Nano для пайки и ремонта микросхем | Продавец: Phonefix | Описание Mechanic M35 10CC Nano Flux Paste для ремонта пайки чипов BGA на материнской плате мобил... | |

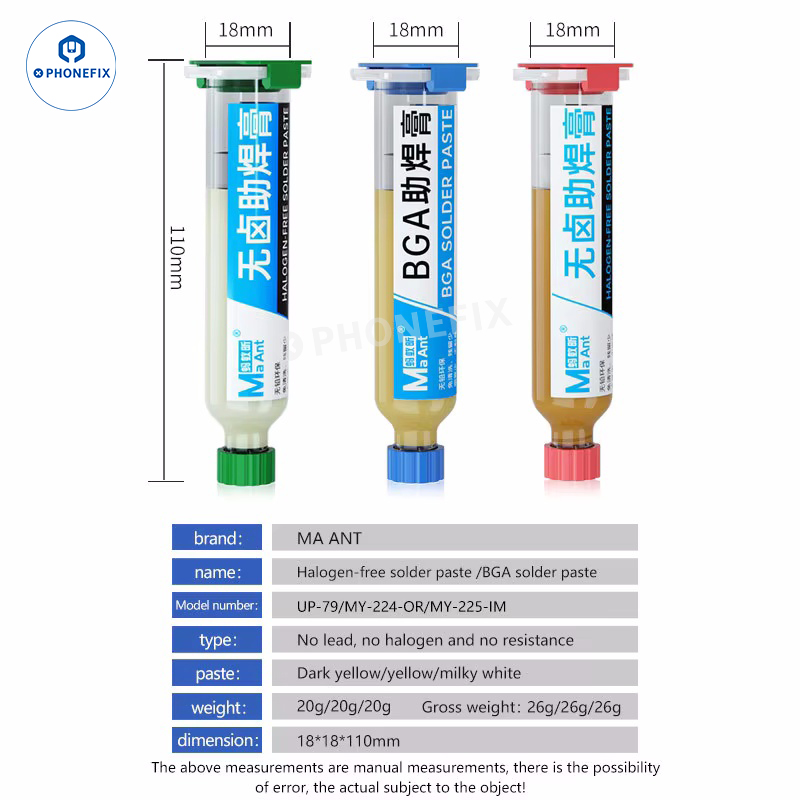

| MaAnt BGA Solder Paste Halogen-free Lead-free Repair Flux | Продавец: Phonefix | MaAnt UP-79 MY-224 MY-225 halogen-free solder paste for mobile phone/electronic circuit board CPU... | |

| JTX Nano Conductive Silver Paste For Phone Screen Line Circuit Repair | Продавец: Phonefix | JTX Nano Conductive Silver Paste repairs iPhone screen/green screen/white screen lines issues cau... |