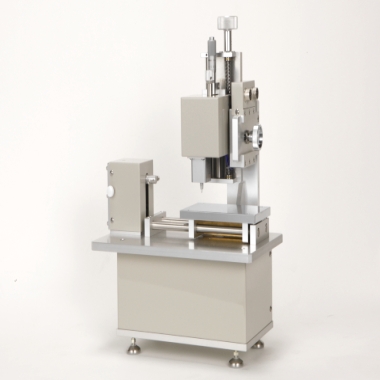

Oxidizing liquid time pressure tester

Conforms to UN Recommendations on the Transport of Dangerous Goods - Manual of Tests and Criteria 11.6.1 Test 1(c)(i): Time/Pressure Test, 12.6.1 Test 2(c)(i): Time/Pressure Test, 23.4.1 Test C.1: Time/Pressure Test, and GB/T 21579-2008 Time/Pressure Test Method for Dangerous Goods.

Applications

The Oxidizing Liquid Time Pressure Tester is used to determine the potential of a liquid substance to increase the combustion rate or intensity of a combustible substance when mixed with it.

Standards

GB/T 21620:Dangerous goods - Test methods for oxidizing liquids

GB/T 21579-2008:Dangerous goods - Test method of time/pressure

NY/T 1860:Guidelines on the determination of physico-chemical properties of pesticides

Features

1) Embedded processor, Windows CE operating system

2) 8-inch LCD touch screen can display the test status in real time

3) Automatic detection of pressure vessel air tightness (by detecting the initial pressure drop rate)

4) With ignition sound and light alarm function

5) Stainless steel seamless welded inner liner and pressure vessel, pressure sensor with corrosion resistance, high temperature resistance, high pressure resistance

6) Automatic timing and high-precision pressure detection system, real-time detection and display of pressure changes

7) With automatic pressure relief device, after the test, automatically punctured explosion-proof sheet, release pressure

8) Automatically draw the pressure curve

9) With reaction residue collection and anti-splash function to avoid external contamination of the sample

10) Remote ignition to ensure the safety of experimental personnel

11) The test process is fully automated without manual intervention, supporting parameter setting, data storage, viewing reports and other functions

Technical Parameters

|

Operating Environment |

(5 to 40)°C, <85%RH |

|

Pressure Transducer Response Capability |

Responds to pressure change from 0MPa-3MPa vessel cavity in 5ms |

|

Pressure Measurement Range |

(0 to 5)MPa |

|

Pressure Measurement Accuracy |

±0.1%FS |

|

Heating Method |

Electronic Ignition |

|

Burst Pressure of Rupture Disk |

2.5MPa ±5% |

|

Standard Timing Range |

(0 to 60)s |

|

Timing Display Resolution |

0.01ms |

Accessoriess

1. Core Working Components

Pressure Testing Unit:

Stainless steel seamless welded liner + pressure vessel (corrosion resistant, high temperature resistant, provides the necessary sealing environment for testing, conforms to UN/GB standards);

Corrosion resistant and high temperature resistant pressure sensor (real-time acquisition of pressure data within the vessel, supports time-pressure curve recording).

Control and Display Components:

Embedded processor (equipped with Windows CE operating system);

8-inch LCD touchscreen (real-time display of test status and time-pressure curve).

Functional Modules:

Automatic pressure vessel airtightness detection component (determines sealing status based on initial pressure drop rate);

Ignition audible and visual alarm device (triggers warning in case of test abnormalities).

2. Auxiliary Accessories

Sample Handling:

Pipette/Quantitative Sampler (accurately measures oxidizing liquid samples),

Dedicated liquid sample container (compatible with pressure vessel loading);

Calibration and Maintenance:

Pressure calibration standard device (calibrates pressure sensor accuracy),

Dedicated cleaning agent + cleaning brush (cleans pressure vessel liner);

Data Management:

USB flash drive (exports test data, time-pressure curve, and reports).

Test Procedures

1. Sample Preparation: Homogenize the oxidizing liquid sample to be tested (e.g., by stirring) to ensure no stratification and no impurities.

Measure the specified volume of sample according to the corresponding standard requirements using a pipette/quantitative sampler, and set aside.

2. Instrument Preparation: Connect the power supply and start the instrument. The embedded processor will automatically complete a fault self-check.

Access the calibration interface via the 8-inch touchscreen and calibrate the pressure sensor using the pressure calibration standard device.

Activate the airtightness detection module to automatically detect the sealing status of the pressure vessel (if the initial pressure drop rate meets the standard requirements, it passes).

3. Sample Loading and Sealing: Load the quantified liquid sample into the dedicated sample container inside the pressure vessel.

Close and lock the pressure vessel to ensure the cavity is completely sealed.

4. Parameter Setting and Test Start: Select the corresponding test standard (e.g., UN Test 1 (c)/GB/T on the touchscreen and set parameters such as the test duration.

Click "Start," and the instrument will automatically begin the test. The touchscreen will simultaneously display pressure changes and test progress. 5. Test Monitoring and Recording

During the test, if abnormal pressure fluctuations occur, the audible and visual alarm will be automatically triggered.

After the test, the instrument will automatically record key data such as the time-pressure curve, peak pressure, and pressure rise rate.

6. Completion and Data Export

After the pressure vessel has cooled and depressurized, open the chamber and clean the lining and sample container.

Export the test data and report to a USB flash drive via the touchscreen.

Turn off the instrument power to complete the operation.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Office Chair Caster Durability Tester | The Office Chair Caster Durability Tester is designed to evaluate the rolling durability, structural reliability, and service life of office chair ... | |

| Glove Cut Resistance Tester | Product Introduction: The machine is used to test the cutting resistance of gloves. Under the specified load, the blade cuts the sample to measure... | |

| UV Lamp Aging Test Tester | Standards ASTM D4329 Standard Practice for Fluorescent UV Exposure of Plastics ASTM D4587 Standard Practice for Fluorescent UV-Condensation Expos... | |

| Athletic Footwear Shock Attenuating Tester | The Athletic Footwear Shock Attenuating Tester is primarily used to test the shock energy absorption performance of single materials or material st... | |

| High temperature vacum friction & wear tester | The working principle of a high-temperature vacuum friction and wear testing machine is to simulate the friction and wear behavior of materials u... |

Похожие товары

| Gas Oxidizing Property Tester | Продавец: Standard International Group (HK) Limited | Product Description Conforms to ISO 10156-2010 “Gases and Gas Mixtures Selection of Cylind... | |

| Battery Powder Compaction Density Measurement System | Продавец: Standard International Group (HK) Limited | The Battery Powder Compaction Density Measurement System is a precision testing system designed... | |

| Battery Powder resistance tester | Продавец: Standard International Group (HK) Limited | The Powder Resistivity Meter is a precision testing system designed to measure electrical resisti... | |

| KES-SESRU surface roughness/friction tester | Продавец: Standard International Group (HK) Limited | TheRoughness/Friction Tester analyzes hand movements-particularly, strokes-performed by artisans ... | |

| Air Permeability Tester STD- F8 | Продавец: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... |