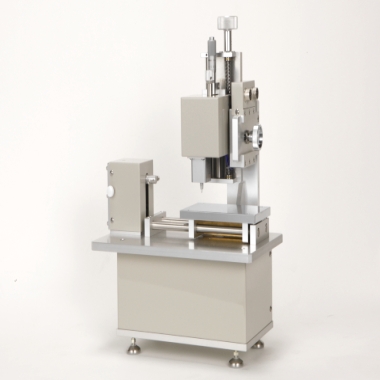

Wire Torsion and Winding Tester

The Wire Torsion and Winding Tester is a versatile instrument designed to perform both torsion and winding tests on metal wires. It evaluates the mechanical properties, formability, and ductility of wires, providing essential data for quality control, research, and production optimization. This tester is widely used in aerospace, metal material processing, tire manufacturing, as well as in universities, scientific research institutions, technical supervision, and quality inspection departments.

Application

(1) Torsion and winding performance testing of metal wires.

(2) Evaluating wire formability, elasticity, and torsional resistance.

(3) Quality control in wire production and processing.

(4) Research and development of aerospace wires, steel wires, and conductive wires.

(5) Testing wires used in automotive, construction, and industrial equipment.

(6) Laboratory experiments and materials research in universities and technical institutes.

Standards

(1) GB/T 2611-2007 – Testing Machine General Technical Requirements.

(2) ISO 7800:1984 – Test Method for Unidirectional Torsion of Metal Wires.

(3) ISO 9649:1990 – Test Method for Bidirectional Torsion of Metal Wires.

(4) GB/T 3428-2002 – Zinc-Coated Steel Wire for Overhead Stranded Wire: Winding Test – Torsion Test.

(5) GB/T 239-1999 – Torsion Test of Metal Wire.

(6) GB/T 2979-2020 – Metal Materials Wire Winding Test Method.

(7) ASTM and JIS standards related to torsion and winding testing of metallic materials.

Features

(1) Dual functionality: performs both torsion and winding tests on a single machine.

(2) Provides comprehensive evaluation of wire mechanical properties.

(3) Compliant with multiple national and international standards.

(4) Streamlined testing process, improving efficiency compared to separate machines.

(5) Controlled testing parameters for repeatable and reliable results.

(6) Supports quality assurance in production and R&D applications.

(7) Adjustable sample setup to accommodate various wire diameters and lengths.

Parameters

| Parameter | Specification |

|---|---|

| Torsion sample size | Diameter 1–10 mm |

| Winding sample size | Diameter 1–6 mm |

| Distance between two plus heads | 0–500 mm, adjustable |

| Twisting/Winding speed | 0–2.0 r/s, adjustable, error <±10% |

| Power supply | AC 220V ±10%, 50 Hz |

Accessories

(1) Main testing machine

(2) Sample holders for torsion and winding tests

(3) Adjustable clamps and positioning rods

(4) Power cable

(5) User manual

Test Procedures

(1) Secure the wire sample in the torsion or winding fixture.

(2) Adjust the distance between the two heads according to the sample length.

(3) Set the desired twisting or winding speed.

(4) Start the machine to perform torsion or winding cycles.

(5) Observe the wire performance during testing.

(6) Record results and repeat for additional samples if necessary.

Maintenance Information

(1) Regularly inspect clamps, heads, and moving parts for wear or damage.

(2) Ensure the machine is clean and free from debris.

(3) Check power supply and electrical connections for stability.

(4) Lubricate moving components according to manufacturer recommendations.

(5) Handle the sample fixtures and torsion/winding heads carefully to avoid misalignment.

(6) Calibrate the machine periodically to maintain measurement accuracy.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Oxidizing Solids Tester | Conforms to UN Recommendations on the Transport of Dangerous Goods - Manual of Tests and Criteria 34.4.1 Test O.1: Test for oxidizing solids, 34.4.... | |

| Coating abrasion resistance test device | Product Introduction: The determination of scratch resistance of the coating is very similar to the scratch test of the coating, but this test met... | |

| Standard light source sample table | Standards ISO 3664:2009: Meets international standards for graphic arts and photography view conditions. DIN 6173-2: European norm for illuminant... | |

| FPC Flex Durability meter | Standard ASTM F392 Product features 1. the stepper motor drive, high-precision positioning, low noise, can be used for a long time 2. program-c... | |

| Micro Rapid Closed Cup Flash Point Tester(Pensky Martens) | Automatic Flash Point Tester designed for accurate and repeatable determination of the flash point of petroleum products using the Pensky-Martens c... |

Похожие товары

| Gas Oxidizing Property Tester | Продавец: Standard International Group (HK) Limited | Product Description Conforms to ISO 10156-2010 “Gases and Gas Mixtures Selection of Cylind... | |

| Battery Powder Compaction Density Measurement System | Продавец: Standard International Group (HK) Limited | The Battery Powder Compaction Density Measurement System is a precision testing system designed... | |

| Battery Powder resistance tester | Продавец: Standard International Group (HK) Limited | The Powder Resistivity Meter is a precision testing system designed to measure electrical resisti... | |

| KES-SESRU surface roughness/friction tester | Продавец: Standard International Group (HK) Limited | TheRoughness/Friction Tester analyzes hand movements-particularly, strokes-performed by artisans ... | |

| Air Permeability Tester STD- F8 | Продавец: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... |