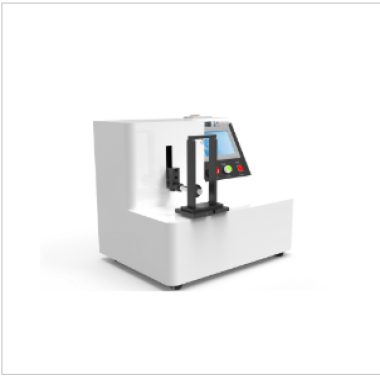

Nasal Oxygen Cannula Tester

This device is used to test various performance characteristics of nasal cannulas, such as airflow resistance and resistance to kinking. It is also known as a nasal cannula airflow resistance and kinking resistance tester or nasal cannula testing equipment. This device is suitable for all nasal cannulas, whether they are standalone or used in conjunction with humidifiers or masks. It can test parameters such as airflow resistance, resistance to kinking, leakage, pressure resistance, and bending resistance (patency).

Applications

The nasal oxygen tube tester is mainly used to test key parameters of nasal oxygen tubes, such as oxygen content, flow rate, and pressure, as well as to evaluate their physical properties like pressure - resistance, crush - resistance, and air permeability. This tester plays an important role in various aspects, including the production, quality control, and pre - use inspection of nasal oxygen tubes, ensuring that nasal oxygen tubes can provide patients with a stable and effective oxygen supply. Specifically, its main uses are as follows:

- Production Quality Control: During the production of nasal oxygen tubes, manufacturers can use this tester to conduct sampling inspections on finished products, ensuring that each batch of nasal oxygen tubes complies with relevant standards and regulations. - Pre - use Inspection: Before using nasal oxygen tubes, medical institutions can use this tester to conduct quality inspections to ensure that the performance of nasal oxygen tubes is stable, safe, and reliable. - Research, Development and Improvement: The nasal oxygen tube tester can also be used in the research, development and improvement process of nasal oxygen tubes, helping R & D personnel understand the performance characteristics and deficiencies of nasal oxygen tubes, so as to make targeted improvements and optimizations.

Standards

YY/T 1543 - 2017:Nasal Oxygen Cannula

GB/T 1962.1-2005:Conical fittings with a 6%(Luer) taper for syringes, needles and certain other medical equipment -- Part 1: General requirement

Features

• Supports five major testing functions: airflow resistance, crush resistance, leak testing, and pressure resistance.

• 7-inch color touchscreen control with an intuitive interface for a significantly improved user experience.

• The device is equipped with a miniature printer for real-time printing of test results.

• Equipped with a high-precision pressure sensor, allowing for stable control of output pressure via a rotating pressure knob.

• Equipped with a high-precision flow meter for accurate measurement of flow through the tubing.

• Unique rotary design accommodates crush resistance testing of nasal oxygen tubes with various inner diameters.

• Features a universally designed conical test interface, meeting the testing requirements of most products on the market.

• The device has powerful built-in data storage capabilities.

• Miniature printer and universal USB data interface for convenient data output and transfer.

• Intelligent features such as overload protection and power-off memory effectively ensure user safety.

• Free software upgrade service is provided.

Technical Parameters

| Parameter | Specification |

|---|---|

| Test Pressure Range | Usually covers 0 - 600kPa or higher, to meet testing requirements of nasal oxygen tubes with different specifications and materials |

| Test Flow Range | Simulates normal oxygen supply flow (e.g., not less than 15L/min), ensuring air permeability of nasal oxygen tubes in actual use |

| Accuracy | High level of accuracy; e.g., pressure accuracy reaches ±1% or higher, ensuring test result accuracy and reliability |

| Data Collection and Display | Equipped with data collection card and display screen, which collect and display real-time test data (pressure, flow rate, time, etc.) for easy observation and recording |

| Clamping Device | Fixes nasal oxygen tubes to keep their position stable (no displacement/shaking during testing); adaptable to nasal oxygen tubes of different specifications and shapes |

| Operation Interface | Simple and clear for easy operation; some testers are equipped with touch-screen control and menu-style functions to improve operational convenience |

Accessoriess

1 main unit;

1 set of testing software;

1 instruction manual;

1 certificate of conformity;

1 warranty card;

1 delivery receipt;

1 nameplate;

1 power cord;

1 set of wrenches;

Several brochures;

1 x 1/8 barbed connector;

1 x 1/8 Luer connector (male).

Test Procedures

1. Pre-test Preparation

Check that the instrument's power supply and pipeline connections are normal, start the instrument and preheat it to a stable working state.

Calibrate the pressure and flow sensors (refer to the instrument calibration guide) to ensure that the detection accuracy meets the requirements.

Clean the fixtures and pipelines of impurities, prepare the nasal oxygen cannula samples to be tested, and record the basic information of the samples, such as specifications and materials.

2. Sample Installation

Connect the nasal oxygen cannula sample to the corresponding pipeline interface of the instrument, and use a special fixture to fix both ends of the sample, ensuring that the connection is sealed without leakage and that the sample is not bent or displaced.

3. Test Parameter Setting

Through the instrument's touch screen interface, select the target test item (such as airflow resistance, pressure resistance, leakage test, anti-flattening performance, etc.).

According to the corresponding standard for nasal oxygen cannulas (such as YY/T 1543-2017), set the corresponding test parameters (such as test flow rate, pressure threshold, pressure holding time, etc.), and save the parameters after confirmation.

4. Starting the Test

After confirming that the sample connection and parameter settings are correct, click the "Start" button. The instrument will automatically execute the test process, collecting and displaying data such as flow rate, pressure, and time in real time.

5. Test Process Monitoring

During the test, observe the data changes on the instrument interface and the sample status. If any abnormalities such as loose pipelines or leaks occur, pause the test immediately and handle the issue.

6. Test Completion and Cleanup

After the test is completed, the instrument will automatically shut down. Record or export the test data (such as airflow resistance value, pressure resistance results, etc.).

Loosen the fixture and remove the sample, clean the fixture and pipelines, turn off the instrument power, and prepare the test report.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Catheter Guidewire Friction Tester | The Catheter Guidewire Friction Tester is designed to accurately measure the frictional forces between catheters and guidewires. It is a critical t... | |

| Suture Needle Cutting Force Tester | The Suture Needle Cutting Force Tester is a precision instrument specifically used to detect the force required by medical suture needles during th... | |

| Catheter Leakage and Compliance Tester | The Catheter Leakage and Compliance Tester is a professional testing device used to evaluate the expansion capacity (compliance) and leak resistanc... | |

| Automated Freezing/Pour Point Chiller Tester | Product Introduction: The automatic freezing point pouring point Freezing point tester is suitable for petroleum, biological, chemical and other f... | |

| Falling Ball Impact Resistance Testing Machine | Product Introduction: Falling ball impact tester is suitable for testing the fastness of plastic, ceramic, acrylic, glass fiber and other materials... |

Похожие товары

| Full-Body Garment Stress Tester,FZ/T 70015 | Продавец: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Продавец: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Продавец: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Продавец: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Продавец: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |