beam blank copper mould tube for continuous casting line to produce steel rails

beam blank copper mould tube for continuous casting line to produce steel rails

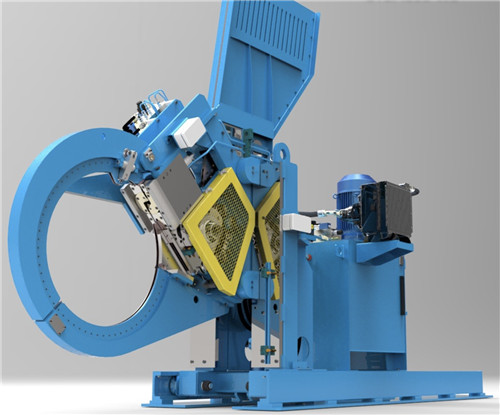

continuous casting line

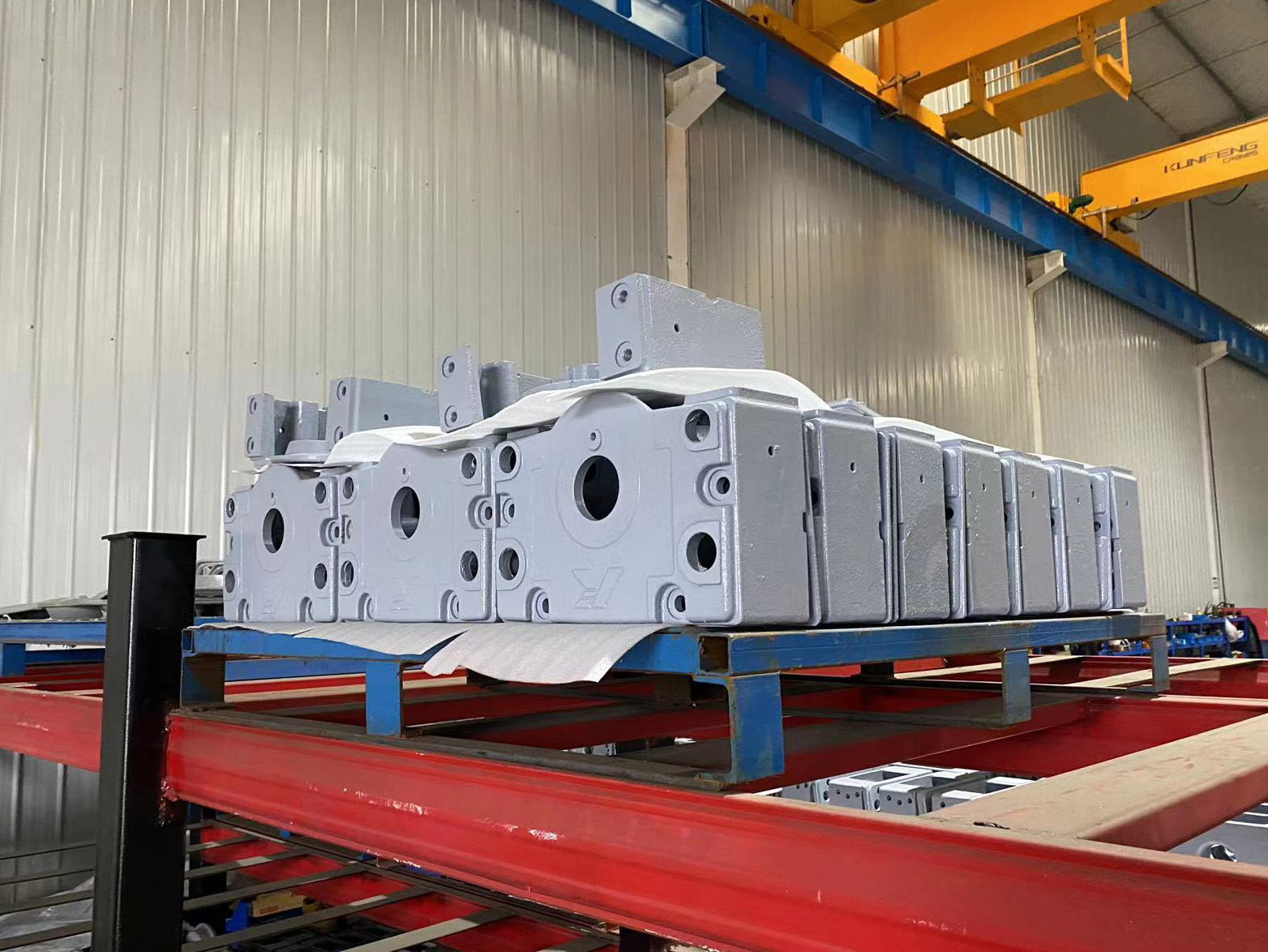

beam blank copper mould tube

beam blank copper mould tube for continuous casting line

beam blank copper mould tube to produce steel rails

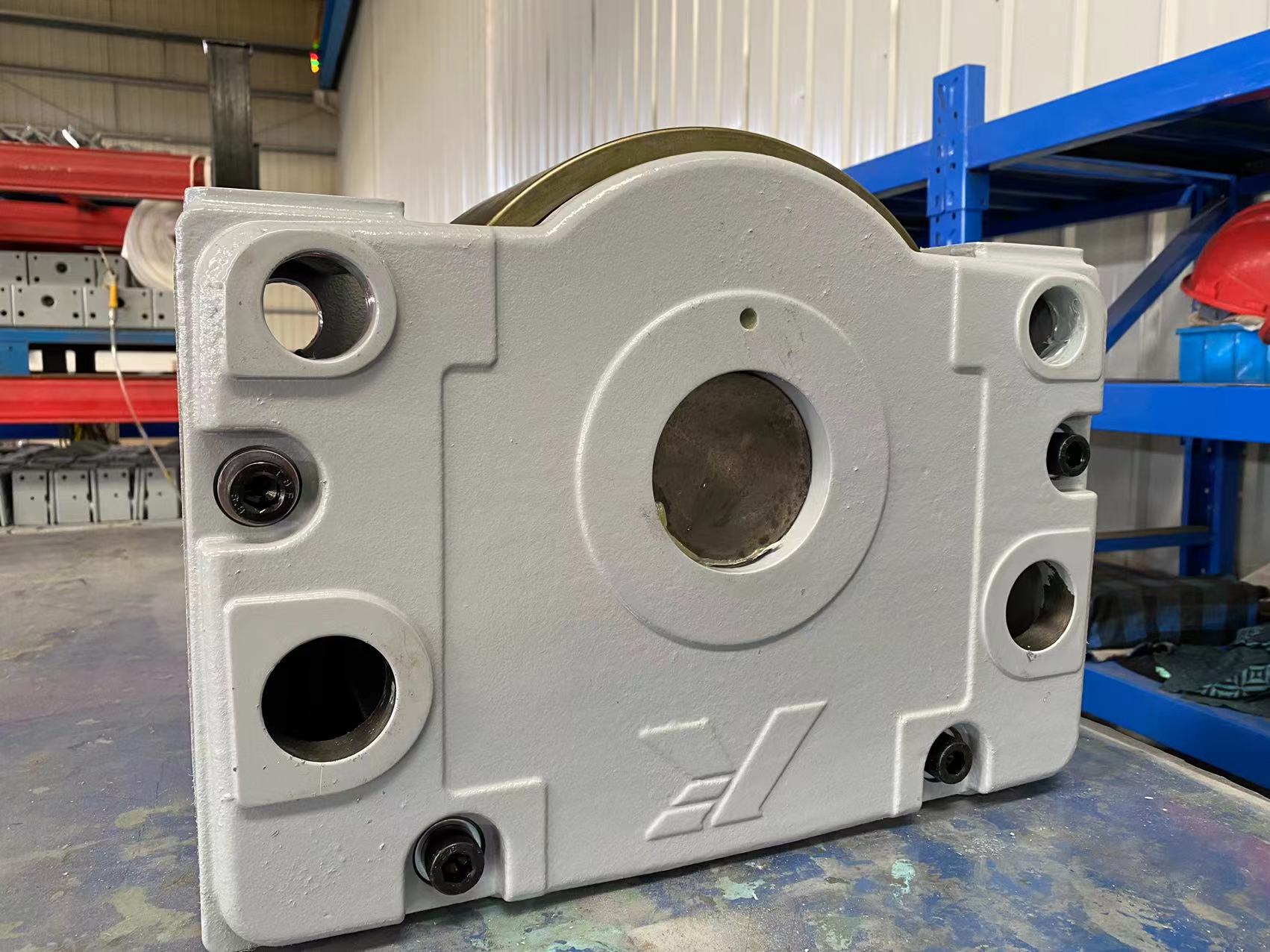

Copper moulds have played an important role in the development of the continuous casting process .Their function is to receive the molten steel and to allow rapid heat transfer from the steel to the cooling water to enable quick solidification. The mould must exhibit excellent thermal conductivity, be resistant for thermal erosion, and be resistant to distortion from thermal stress.

Mould material:The tough working condition of copper mould tube requires its material with excellent tensile strength, enough hardness, low elongation & good thermal conductivity. After many years experiment in our Lab & steel mills, now we are manufacturing copper mould tube with widely accepted material as : Tp2, CU-Ag0.1 & Cu-Cr-Zr.

Typical coatings are : Cr, Ni, Cr-Ni, Ni-Fe, Ni-Co

Beam blank copper mould tube specification:

Size: as per customer’s drawing, Radius: 6000-17000,Length: 700-1000, Taper deign: triple taper

Multi-taper, parabolic tapers & convex.

For more information, please feel free to contact us. Sinom at sinomgroup dot com

Contact informaiton:

Tel:

Mobile:

Web:

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| completed production line of straight bar, bar-in-coil, and wire rod | completed production line of straight bar, bar-in-coil, and wire rod Bar in Coil System SINOMultra-high-speed wire rod lines regularly reach produ... | |

| Rebar and H Beam Bundling/Tying Machine supplier | Rebar and H Beam Bundling/Tying Machine supplier Rebar and H Beam Bundling/Tying Machine Main Features of SINOM rebar Bundling Machine/ tying mach... | |

| electric arc furnace used for melting quality carbon and alloy steel | electric arc furnace used for melting quality carbon and alloy steel electric arc furnace electric arc furnace for melting quality carbon electric ... | |

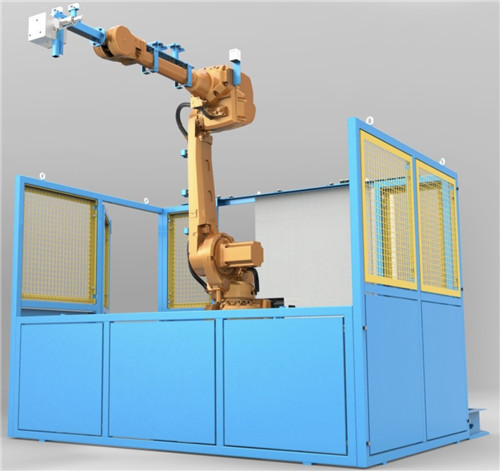

| Coil Marking Robot | Coil Marking Robot The SINOM Coil Robot Marker is designed to mark OCR and 2D data-matrix codes directly on the surface of the hot or cold coils (... | |

| back up roll for hot and cold rolling mill | Productionofforgedsteelbackuprollsrangingfrom5to170tonnesfinished weightLeadingsupplierofrollsforuseinferrousandnonferrousapplications;bothhotandc... |

Похожие товары

| Система привода колесного блока с мотор-редуктором для крана | Продавец: KunFeng heavy industry (suzhou) co., LTD. (KF CRANE) | Полная система ведомых колес включает в себя колеса, электрический асинхронный двигатель переменн... | |

| Система колесных блоков DRSA | Продавец: KunFeng heavy industry (suzhou) co., LTD. (KF CRANE) | Система колесных блоков KUNFENG® DRSA отличается большой грузоподъемностью при компактных раз... | |

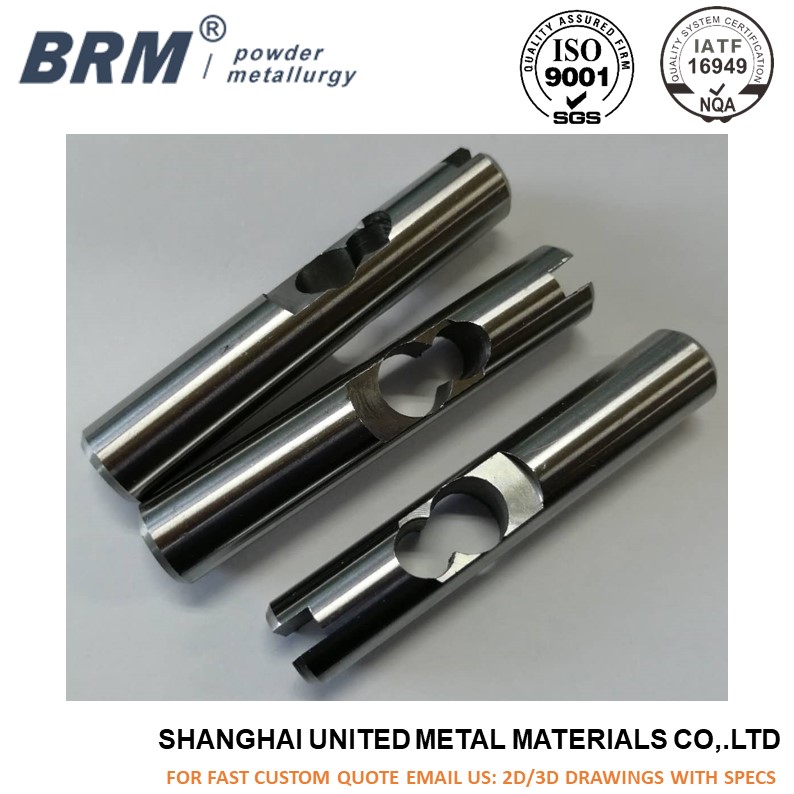

| CNC machining precision steel parts | Продавец: BRM МИМ Технология, Запчасть из Нержавеющей Стали | BRM metal injection molding specializes in Powder Metallurgy for all industries with more than 20... | |

| Precision CNC machining platen of rotor for automotive transmission parts | Продавец: BRM МИМ Технология, Запчасть из Нержавеющей Стали | Product Specifications /Features : Feedstock– Injection molding – De-binding – ... | |

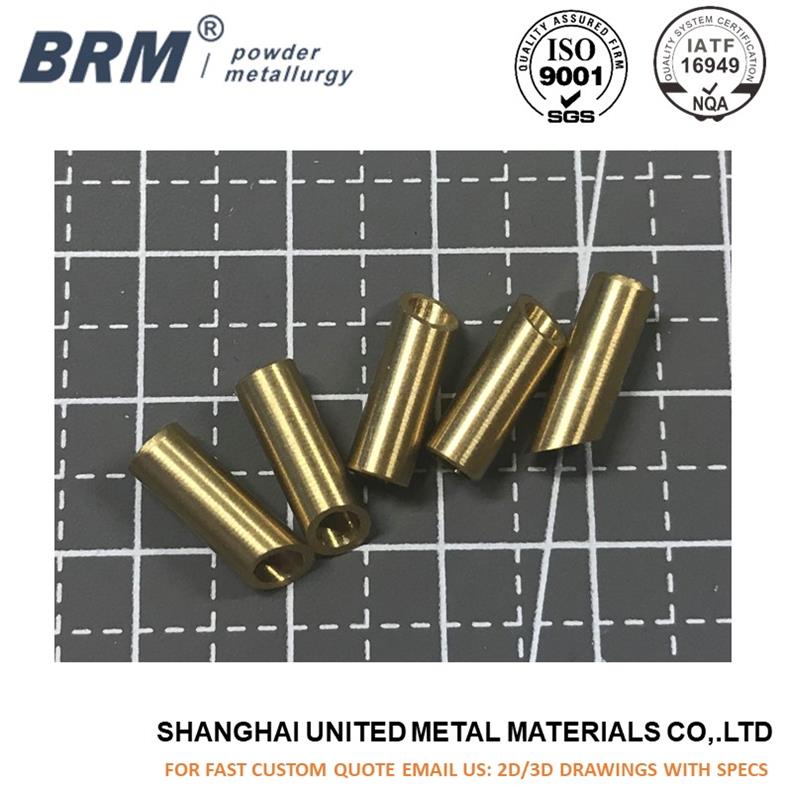

| CNC machining CuZn36 brass bushing for automotive parts | Продавец: BRM МИМ Технология, Запчасть из Нержавеющей Стали | Product Specifications /Features : Feedstock– Injection molding – De-binding – ... |