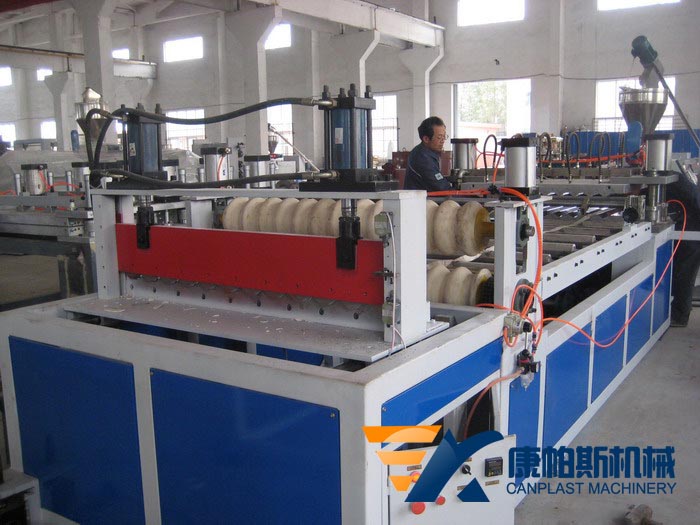

PP,PVC wave board production line

Все товары поставщика

PP,PVC wave board production line PP,PVC wave board production line, also called wave tile production line, according to different materials, it can be divided into PP, PE, PC, PVC and other materials, multilayer and single layer. According to the production process, it can be divided into single screw wave sheet extrusion line, and double screw wave sheet extrusion line. it can also be divided into direct forming through die or forming through pressing roller. Direct forming through die, according to the required size, forming plate is produced in wave shape in production processing. this kind of forming plate has the advantages of fast forming speed, high capacity, stable quality, small deformation after the forming processing. Forming through pressing roller is three roller cooled down the sheet, and using upper and lower pressing roller to get the wave sheet according to the requirements, it has the advantages of high production speed, convenient adjustment, the shape and wave height can be adjusted at any time, only need to change different roller, wave sheet with different shape can be produced, such as trapezoidal, circular. Screw has special material mixing function and high plasticization design, to ensure stable and high speed material extruding out. Statically multi-wing type heating-radiating fan, equipped with separate closed type barrel cover made by stainless steel, it has excellent ventilation and heat dissipation effect. Extrusion die adopt special double throttle design, the width and thickness adjustment are more accurate. Gearbox adopt anti-noise box design. gears are specially treated through high hardness, with forcing lubricating system, ensures the reducer in static operation. Double flow pannel hydraulic quick changer to ensure the screen changing fast, maintain the continuity of production. High precision three roller calender to ensure the product is smooth and flat. Close-open type infra-red pre processor, ensure the heat requirement before molding and fast operation. Synchronous composite molding device, ensure rapid and accurate forming. The haul-off unit compact two roller haul-off structure, roller spacing is freely adjustable, frequency conversion stepless speed regulation, to adapt to the demand of various extrusion speed, and to ensure stable production. Double roller haul-off machine matched with precision edge cutting and edge winding device, ensure stable operation. Bilateral type special design cutting device using imported high quality steel alloy blade, cutting is fast and smooth. Cutting device reasonable cutting style, ensures the rapid and stable, smooth cutting. Control system various control system selection (such as PLC automatic control system), to meet the different needs of customers. The performance of wave sheet production line is better, and quality is higher, the structure is more compact and reasonable. In addition, by replacing some parts, it can be used to produce wood plastic wave sheet, PVC transparent wave board, light transmission rate can be up to 85%.

Qingdao Canplast Machinery welcome friends around the world to inquire with Wave sheet production line e

Service for PP,PVC wave board production line

Pre-Pre-sale customers can consult to our company for various technique and business, our company will provide related information to facilitate reference, and provides the corresponding marketing information, sales price, sales method, to help customers know the entire market.

In-sIn Insale after the two sides signed the contract, our company will provide corresponding design of water, electricity, air, ground installation diagram, according to customer requirements and the actual situation. After the production completed, we should inform customer in advance in order to inspect machine testing, and provide various convenience like airport pick-up, catering, hotel booking etc.

PP,PVC wave board production line After-sales after equipment completed in our company and debugging qualified, equipment arrived customer is factory, our technician should arrive customer is factory in time at customer is requirements to do installation, commissioning, personnel training, technology transfer, until the user can operate independently, and produce qualified products.

Formulation and technical support all production equipment of our company are free of charge to provide the production formula and debug the equipment according to the formula. Any problem in the production process can call us for consultation.

Wave sheet production line Maintenance and warranty for equipment all equipment of our company are provided with corresponding accessories, the warranty period of our equipment is one year, operation manual and maintenance manual are offered.

PP,PVC wave board production line Main technical parameter

|

Extruder model |

SJ100/38 |

SJ105/33 |

SJSZ80/156 |

|

Raw material |

PC |

PP |

PVC |

|

Product width (mm) |

1400 |

1050 |

1200 |

|

Product thickness (mm) |

|||

|

300 |

300 |

350 |

Qingdao Canplast Machinery Co., Ltd Our main products are PP-PC hollow grid board production line, PE, PP, PS, PVC Board Production Line, WPC furniture-cabinet board production line,PP-PE-PVC Wood Plastic Composite Profile Extrusion Line, PP-R Cold-Hot Water Supply Extrusion Line, PVC Pipe Extrusion Line, PE-PP Gas/Water Supply Pipe Extrusion Line.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| PVC Marble Panel Production Line | PVC Marble Panel Production Line PVC marble panel production line features with compact structure, superior performance. The optimized design of th... | |

| PE, PP, PS, PVC thick board production line | PE, PP, PS, PVC thick board production line Characteristics of PP, PE, ABS, PVC thick board production line products manufactured by PP, PE board p... | |

| WPC Construction Board Production Line | WPC Construction Board Production Line Features of Wood plastic building template production line, PVC construction board extrusion production line... | |

| PVC glazed tile production line PP,PVC wave board production line PVC glazed tile production line is composed of two conical double screw extruders, one single screw extruder, co-extruding distributo | PVC glazed tile production line PP,PVC wave board production line PVC glazed tile production line is composed of two conical double screw extruders... | |

| Wood Plastic furniture plate production line | Wood Plastic furniture plate production line Wood plastic furniture plate production line, also known as the PVC wood furniture plate production li... |

Похожие товары

| PVC WPC Panel Board Extrusion Line | Продавец: JWELL MACHINERY(CHANGZHOU)CO., LTD | Jwell extrusion has specialized in plastic extrusion machines and complete solutions for over 25 ... | |

| PVC Window Profile Extrusion Line | Продавец: JWELL MACHINERY(CHANGZHOU)CO., LTD | Our high quality PVC window profile extrusion line equipped with special conical twin screw extru... | |

| PVC Window Door Profile Extrusion Line | Продавец: JWELL MACHINERY(CHANGZHOU)CO., LTD | pvc profile machine manufacturer, pvc profile production line factory We have specialized in pvc... | |

| PVC Wall Panel Extrusion Line | Продавец: JWELL MACHINERY(CHANGZHOU)CO., LTD | JWELL Machinery specializes in complete solutions for various PVC wall panel extrusion lines, fro... | |

| PVC Trunking Extrusion Line | Продавец: JWELL MACHINERY(CHANGZHOU)CO., LTD | By adopting the European advanced extrusion technology, we successfully developed the high speed ... |