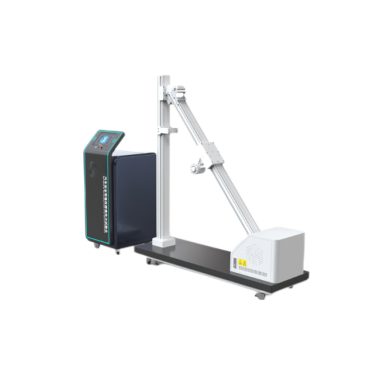

Chemical Reactor Cleaning System

Total ChemicalReactor Cleaning Systems

Reactor Cleaning Systems are designed to safely and effectively peel and clean scale stuck to the inside of polymerization tanks, reactors, and storage tanks by using high-pressure water. We design and manufacture all the relevant items for the system such as high-pressure pump, cleaning device, nozzle, and controller etc.

Because of various complex structures such as agitator shaft, it has always been a difficult point in the industry to realize cleaning without dead angle. Due to the following disadvantages of manual cleaning, the cleaning effect can not meet the requirements well all the time:

① Manual operation requires hand-held cleaning, which has the characteristics of high labor intensity, long cleaning time and bad working environment;

② Due to various production processes, there may be toxic or harmful gases in the reactor, which will cause great damage to human body, and even affect human body when cleaning with cleaning solution;

③ The inside of the reactor may be a flammable and explosive working environment, so manual cleaning is dangerous;

④ Because the cleaning method is man-made, the cleaning effect may be greatly affected by human factors;

⑤ Every year, there are reports of casualties in manual cleaning, which has a great impact on the enterprise society and has a great hidden danger;

⑥ Because the reactor generally has mixing shaft, mixing blade, coil, stiffener and other heterogeneous parts, manual cleaning is also difficult

⑦ Because some materials in the reactor are easy to dry and form film, which makes it difficult to clean, the cleaning time is particularly important after the materials in the reactor are emptied.

Working principle:

The setting degree of the system can realize one key operation and high automation degree. The automatic reactor cleaning equipment can clean the parts that are difficult to clean, such as the back, bottom and upper head of the mixing shaft. The high pressure water jet is ejected from the high pressure tank cleaning nozzle to realize the cleaning of this position. Generally, 2-4 cleaning points (which can be set by themselves and adjusted according to the actual situation) are set on the mixing shaft after cleaning one side of the mixing shaft. The pipe coiler is recovered to the original point, and then the arm is swing to the other side of the mixing shaft. The same cleaning method as on the left side sets different cleaning points according to the actual needs, and automatic fixed-point cleaning. Each cleaning point can set the cleaning time as required.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Yarn Loop Length Tester | Compliance Standards FZ/T 70001-2003. FZ/T 71004-2003 Scope of Application Determines loop length of various yarns and knitted loops. Verifies c... | |

| Scott Flex Tester | Product Introduction: Scott kneading tester is suitable for back and forth kneading resistance of leather, leather and woven materials. One end o... | |

| Safety Helmet Flammability Tester | Product Introduction: Safety hat flame retardant performance tester for safety hat flame retardant performance test, high degree of automation, ... | |

| Nail Hammer Snag Tester | The nail hammer snag tester is mainly used to evaluate the ability of fabrics to resist snag. Structure and principle Structure: It is generally... | |

| Geomembrane Hydrostatic and Permeability Tester | Scope of application: It is used to test the hydrostatic pressure resistance and permeability coefficient of nonwoven composite geotextile (one cl... |

Похожие товары

| Seat Bumping and Creep Test Bench | Продавец: Standard International Group (HK) Limited | This test bench is used for simulating the car seat bumping and creep situation when a car is run... | |

| Automobile seat belt fixed point test bench | Продавец: Standard International Group (HK) Limited | Applicable standards: National mandatory standards: GB 15083-2006"Automobile seats, seat fixtur... | |

| Impact strength tester for car seat headrest | Продавец: Standard International Group (HK) Limited | Applicable standards: GB 15083-2006 "Automobile seats, seat fixtures and headrest strength requi... | |

| Impact strength tester for car seat launching headrest | Продавец: Standard International Group (HK) Limited | Main parameters: Impact speed:The impact speed of the tester is usually between 25 and 30km/h, w... | |

| Automobile Headrest Strength Tester | Продавец: Standard International Group (HK) Limited | Applicable standards: GB 11550-2009"Automobile seat headrest strength requirements and test me... |