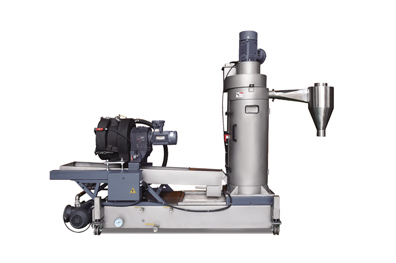

Plastic Extruder & Pelletizer For Masterbatch

Plastic Extruder and PelletizerFor Masterbatch

Masterbatch is one important part of the plastic industry. As a professional extruder supplier and manufacturer, Nanjing KY knows a lot about masterbatch and masterbatch production, and supplies high-quality masterbatch extrusionmachines.

What is Masterbatch?

Masterbatch is an indispensable part of the plastic industry. It can not only give colorful plastic products, improve the value of commodities, improve some properties of plastics, but also give special optical properties of materials.

In the preparation of masterbatch, resin, pigments, additives (dispersants, light stabilizers, etc.) need to be dispersed and distributed efficiently and stably through mixing equipment to ensure that all kinds of materials with different components are evenly distributed in the resin. The masterbatch blending and masterbatch extrusion system of Nanjing KY Chemical Machinery Co., Ltd. is very suitable for masterbatch operations with different colors, such as black, white, and other colors, and different binders, such as PE, PP, PA, ABS, PET, POM, TPE, TPU, etc. Nanjing KY can provide customers with masterbatch machineof high quality.

Nanjing KY, as one of the professional twin screw extruder suppliers, can provide customers with complete extruder pelletizerand masterbatch extrudersolutions, from material transportation, metering feeding, extrusion, granulation, drying, to material packaging.

KY has rich technology accumulation, can provide a customized design to customers according to their prescription requirements, and provide customers with the most suitable solutions and equipment.

What is Masterbatch Extruder?

Masterbatch extruder is an essential machine in the plastic manufacturing industry, especially in the production of color masterbatch. Color masterbatch is a concentrated mixture of pigments, additives, and carriers that are added to natural resins to impart a particular color or enhance their properties. The color masterbatch extruder machine is used to produce color masterbatch in large quantities with high efficiency and accuracy.

A masterbatch machine is a specialized extrusion machine that is designed to create masterbatch pellets. The machine can be used to create both standard and custom color masterbatch. The masterbatch extruder works by melting the resin and mixing it with the pigments and additives in a controlled environment to create a homogenous mixture. The mixture is then extruded through a die to create pellets, which are cooled and collected.

The color masterbatch extruder machine is typically designed with a modular screw system that can be easily modified to accommodate different formulations and production requirements. The screw system is responsible for the mixing and homogenization of the ingredients. The extruder's temperature, speed, and pressure can be precisely controlled to ensure consistent quality and uniformity in the final product.

Masterbatch extrusion is a critical process in the production of color masterbatch. The extruder machine must be able to handle high volumes of material and maintain a consistent mixing ratio. The quality of the final product depends on the accuracy of the mixing process and the quality of the raw materials used.

A color masterbatch extruder is a specialized type of masterbatch extruder that is designed to produce colored masterbatch. The color masterbatch extruder uses specialized pigments and additives that are formulated to produce a specific color or effect. The color masterbatch extruder machine is typically equipped with additional components such as a feeder and a dosing unit to ensure accurate color matching and consistency.

A color masterbatch extrusion line is a complete production line that includes all the equipment necessary to produce color masterbatch pellets. The line typically includes a color masterbatch extruder, a feeder, a dosing unit, and a cooling system. The color masterbatch extrusion line can be customized to meet the specific production requirements of the manufacturer.

In conclusion, masterbatch extruder machines are essential equipment in the plastic manufacturing industry, and color masterbatch extruder machines are specifically designed to produce colored masterbatch. The machines use a modular screw system to melt and mix the raw materials and extrude them into pellets. The color masterbatch extruder machine is designed to handle high volumes of material and maintain a consistent mixing ratio to produce a uniform and high-quality final product. A color masterbatch extrusion line includes all the equipment necessary to produce color masterbatch pellets and can be customized to meet specific production requirements.

Masterbatch Production Process

The masterbatch production process is very strict and generally adopts a wet process. Color masterbatch material is produced by water grinding, phase, water washing, drying, and granulation. Only in this way the quality of products can be guaranteed.

In addition, while the pigment is grinding, a series of tests should be carried out, such as the determination of the fineness of the grout, the determination of the diffusion performance of the grout, the determination of the solid content of the grout, and the determination of the color paste fineness and other items.

As one of pvc extrusion machine manufacturers, we can offer kinds of related products for sale, if you have needs, please contact us.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| SK53 Twin Screw Extruder | Overview of SK53 Twin Screw Extruder SK53 mini twin screw extruder is a mini extruder machine that can be used in engineering plastics, color mast... | |

| AKW Series Water Ring Pelletizer | For some materials such as elastomers with low hardness or easy adhesion, it is recommended to use a water ring pelletizerfor granulation. After ex... | |

| Screw Element | All component materials are supplied by domestic first-line brands or European professional materials suppliers of twin-screw plastics machines. An... | |

| SK Series Co Rotating Twin Screw Extruder | Founded in 1993, Nanjing KY Chemical Machinery Co., Ltd. is currently one of the largest parallel co-rotating twin screw extrusion machinesuppliers... | |

| HKY / SKY Two Stage Extruder | HKY / SKY series two-stage extrusion system: the first stage is HK or SK series high speed and high torque co-rotating twin screw extruder, the sec... |

Похожие товары

| COLMAST®CW1350 (БЕЛЫЙ МАСТЕРБАТЧ) | Продавец: ADC PLASTIC., JSC | COLMAST CW1350 является идеальным выбором благодаря выдающимся преимуществам и сочетанию с различ... | |

| CALMAST®MN570 – ПП НАПОЛНИТЕЛЬ ИЗ КАРБОНАТА КАЛЬЦИЯ MASTERBATCH | Продавец: ADC PLASTIC., JSC | CALMAST MN570 — идеальный выбор, который поможет производителям пластиковых изделий оптимиз... | |

| CALMAST®MF530 – ПП НАПОЛНИТЕЛЬ КАКБОНАТ КАЛЬЦИЯ MASTERBATCH | Продавец: ADC PLASTIC., JSC | CALMAST MF530 — идеальный выбор, который поможет производителям пластиковых изделий оптимиз... | |

| PA6 GF30 Halogen-free FR (A1015F) for Engineering Plastics | Продавец: Suzhou Anmei Material Technology Co., Ltd | PA6 FRis a PA6 with 30% glass-fibers and flame retardant free of halogens. Typical Applicati... | |

| PA6 GF30 Halogenated FR (A1014F) for Engineering Plastics | Продавец: Suzhou Anmei Material Technology Co., Ltd | PA6 GF 30 FRis a PA6 with 30% glass-fibers and halogens flame retardant. PA6 GF30 Halogenated ... |