Plastic Extrusion Line Manufacturer

Plastic Extruder Line Supplier

Plastic extrusion line, as the name implies, is a machinery and equipment specialized in the production of various plastic products, which belongs to a large category of plastic machinery and equipment. Common components are: automatic feeding and mixing system, extruder, die head, shaping cooling system, tractor, cutting device, winding device or stacker.

What is Extrusion Line?

The pvc plastic pipe extrusion lineis a mass production process in which the raw material plastic is melted and formed into a continuous contour. Extruded items include pipes, weather strips, window frames, plastic sheeting, tape and wire insulation. As one of plastic sheet extruder manufacturers, we are proud to have a complete plastic pe pp abs sheet extrusion line, plastic pipe extrusion production line, plastic profile extrusion production line and wood plastic extrusion line. Our engineers and technicians use their expertise and development techniques to adapt to the latest plastic extruders in the rapidly changing market.

Processing of Plastic Extrusion Line

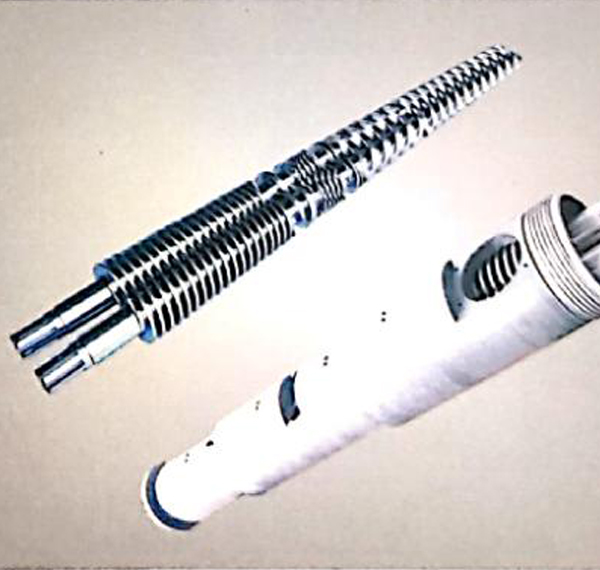

At the beginning, small plastic particles are put into the hopper placed on top of the barrel. The barrel is a heating hollow cylinder, a bit like a very thick tube. The screw type screw rotates inside the barrel. The rotation of the screw brings and pushes the plastic particles into the barrel. When the pill moves to the front end of the cylinder, the friction and electric heat of the cylinder will melt the plastic.

After the plastic melts, the rotating screw continues to act as a pump and forces the molten plastic through the mold. The mold is usually a piece of steel with the desired part shape. Once the melted plastic leaves the mold, it will be shaped like a finished product. Next, pull it through some kind of cooling device, usually using air or water for cooling. After cooling, the product can be rolled up, cut into sections, packaged or subjected to secondary operations.

How do Plastic Extruders Work

The principle of plastic extrusion line: Plastic pellets(eg.PE PP,PVC, PA, EVA) firstly come through hopper. Under the power system, heating, melting the pellets,pressing, screw' s rotation, then generate shear heat, pass the barrel channel, reach screen pack, the products are extruded. This is done by extrusion line machine. The shape is variable according to different mould. This will be finished during plastic production line. Kailitecan also mix color depending on different requirement. General includes standard pipe, sheet,board, profile and different shape's ones.

Send product request

Other supplier products

| SJ Series High Efficiency Single Screw Extruders | High production capacity and high-velocity extrusion. Low-temperature plasticization design guarantees. Two stages style unitary design, reinforc... | |

| PVC Pipe Production Line | PVC pipe production line is mainly used in the manufacture of the plastic PVC pipe with various tube diameters and wall thickness in the aspects su... | |

| PET PP Waterstop Production line | Performance & Advantages Accurate dosing and raw material blending Preheat and dry circulating automatically Even plasticization, stable extrus... | |

| WPC Extrusion Production Equipment | In recent years, wood-plastic products have become popular materials for ordinary household decoration and municipal construction projects. On the ... | |

| SJ Series High Efficiency Single Screw Extruders | SJSingle screw extruderis fetured in high production capacity and high-velocity extrusion, and low-temperature plasticization design guarantees p... |

Same products

| Iron Single Adjustable Cafe Rod Set | Seller: Deqing Bochuang Hardware Co., Ltd | The Iron Single Adjustable Cafe Rod Setis a durable and stylish window treatment solution. Featur... | |

| Competitive Price OEM Waterproof Nylon Injection Molding Parts | Seller: Hebei Erye Rubber & Plastic Products Co.,Ltd | Product Specification Description Products Name: Custom plastic and rubber parts Materials: Plast... | |

| Wholesale Plastic Injection Insert Molding Custom Plastic Parts | Seller: Hebei Erye Rubber & Plastic Products Co.,Ltd | Product Specification Description Products Name: Custom plastic and rubber parts Materials: Pla... | |

| Professional Factory Supply Custom Plastic Injection Molding Service | Seller: Hebei Erye Rubber & Plastic Products Co.,Ltd | Product Specification Description Products Name: Custom plastic and rubber parts Materials: Plast... | |

| China Factory OEM High Quality Plastic Molded Parts Plastic Injection Molding Price | Seller: Hebei Erye Rubber & Plastic Products Co.,Ltd | Product Specification Description Products Name: Custom plastic and rubber parts Materials: Plast... |