steel casting,you can choose Matech Machinery Manufacturest

Shanghai Matech Machinery Manufacture Corporation Ltd.is a company with High quality and excellent service stainless steel casting,steel castinganddie casting parts as the main business. We are committed to providing quality service of casting iron. Shanghai Matech Machinery Manufacture Corporation Ltd.was established in 10 years ago, As a company with a high sense of social responsibility, Matech Machinery Manufacturehas established a high reputation for superior quality and expertise in sand castingx2fc7bb6nfield

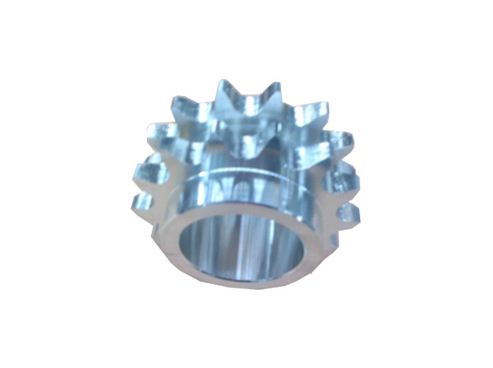

Shanghai Matech Machinery Manufacture Corporation Ltd.is committed to the continuous improvement of thecastservice, become a society, customers, shareholders and employees long-term trust of the company. Our Company adhering to pirit of for the sake of customers, and win-win with customers , and through Matech Machinery Manufacture staff continuous innovation and development to provide first-class lost wax casting use characteristics,Leading service lost wax casting,steel casting the lowest price in the market,High performance-cost lost wax casting for enterprises , is what we have been working for. Details:The process flow of lost wax casting is: pressing plastic mold - open plastic mold - wax injection (mold) - dressing wax mold (welding wax mold) - wax tree (- weighing) - plastering pot - Gypsum vacuum - gypsum natural solidification - baking gypsum - melting gold, casting - fried gypsum - washing, pickling, cleaning (- weighing) - shearing blank (-rolling).The process of lost wax casting is: the original mold (usually silver plate) is surrounded by raw silica gel, vulcanized by heating and pressing, and pressed into a silica gel mold; after cutting the plastic mold in a certain order with a sharp blade, the silver plate is taken out. Obtaining a hollow rubber mold; injecting wax into the hollow plastic mold, and after the liquid wax is solidified, the mold is opened to take out the wax mold; after the wax mold is trimmed, the wax mold is planted in a certain arrangement, and the steel sleeve is placed in a steel sleeve. The high-temperature gypsum slurry is poured; the gypsum is vacuumed, naturally hardened, dried after a certain heating period, and the molten metal is cast (can be cast by the principle of positive pressure or negative pressure); after the metal is cooled, the plaster mold is placed in cold water to be fried. After washing, the castings are taken out, soaked in acid, cleaned, and the blanks are cut to be rolled; after the mold is applied and inlaid, the surface treatment is finished. The positive pressure and negative pressure casting mentioned above refers to the pressure state inside the casting mold during the casting process. Positive pressure casting is represented by centrifugal casting. During the casting process, when the molten metal enters the mold, the pressure in the mold is atmospheric pressure. In order for the liquid metal to enter the mold, the metal must overcome the atmospheric pressure. Centrifugal casting is the liquid metal. The crucible and the mold are mounted on a high-speed rotating disc, and the liquid metal flows at a high speed in the normal direction (radial direction) of the disc by the action of centrifugal force, thereby generating an injection action into the mold-that is, during the "positive pressure casting" process. At the moment when the molten metal enters the cavity of the mold, the internal pressure of the mold is greater than the external pressure of the mold, and the difference between the two is greater than 0, so it is called "positive pressure casting"; "negative pressure casting" is typical by vacuum suction casting, during the casting process. When the molten metal enters the mold, the pressure inside the mold is less than the external pressure of the mold, and the difference between the two is less than 0, so it is called "negative pressure casting" - of course, the negative pressure in the mold must be completed by a vacuum pump connected to the mold. Liquid metal naturally enters the mold under the action of atmospheric pressure.

With the rapid development of business simultaneously, Matech Machinery Manufacture always keeps the balance between external opportunities and internal management, attaching great importance to the training and shaping of core competitiveness. The company will take customer service value as the core competitiveness of enterprises. Adhering to spirit of enterprise:acting with integrity , pursuit of excellence, respect for the individual , Matech Machinery Manufacturestrives to provide customers with Good service attitude investment casting. More details in the Matech Machinery Manufactureofficial website:

Send product request

Other supplier products

| Good choice of selecting casting for you | Shanghai Matech Machinery Manufacture Corporation Ltd.is a aluminum casting the approval as the carrier, stainless steel casting,casting iron,die c... | |

| Matech Machinery Manufacture provides you withdie castand w | Shanghai Matech Machinery Manufacture Corporation Ltd.( referred to as Matech Machinery Manufacture), located in Rm.503, 1st Building , Wisdom ... | |

| Only die casting gives you everything that you need to desi | Shanghai Matech Machinery Manufacture Corporation Ltd.has a group of high-quality, experienced, responsibility, in particular actual combat experie... | |

| Give these over casting a try, you will be amazed | Shanghai Matech Machinery Manufacture Corporation Ltd. was founded in 10 years ago, After a period of rapid development, it has developed into a co... | |

| Let you worry-free after the sale is the atitude of stainle | Shanghai Matech Machinery Manufacture Corporation Ltd. is a professional supplier which provides a variety of stainless steel casting, to provi... |

Same products

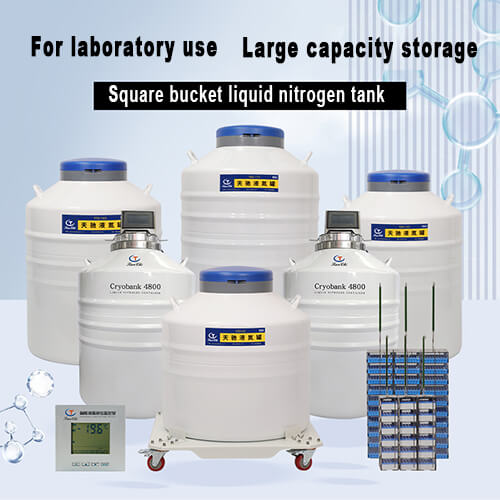

| Togo cell freezing container KGSQ Liquid Nitrogen Field Tank | Seller: Henan Tianzhidao Biological Technology Co., Ltd | The use of liquid nitrogen tanks covers scientific research, animal husbandry, gourmet food, beau... | |

| White Fiberglass Surface, Packaging Type: Roll at | Seller: Jiangsu Zeyusen Carbon Fiber Technology Co., Ltd. | Fiberglass surface mat is mainly used in the surface layer of fiberglass merchandise, it has th... | |

| Burundi liquid nitrogen container for cell storage KGSQ cryo dewar | Seller: Henan Tianzhidao Biological Technology Co., Ltd. | The use of liquid nitrogen tanks covers scientific research, animal husbandry, gourmet food, beau... | |

| 3x large magnifying glass with LED - evenly illuminates viewing area | Seller: PHONEFIX Technology Co., Ltd. | RECTANGULAR SHAPES THE WAY YOU NATURALLY READ: The rectangular lens is especially design to sim... | |

| NDT3055L 3055L SOT-223 car computer board Transistor | Seller: Shenzhen weikexiu technology Co.,Ltd | The NDT3055L 3055L SOT-223 car computer board transistor is a critical component used in the repa... |