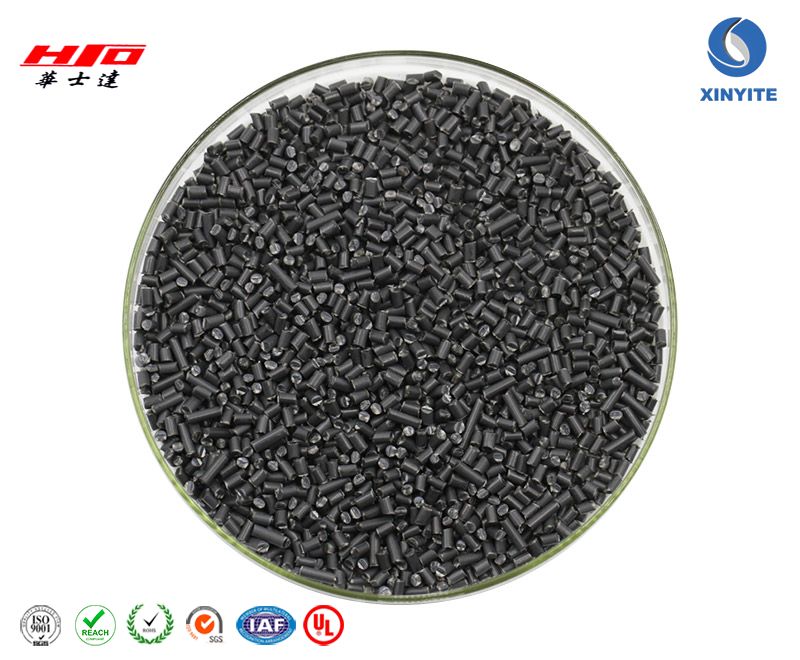

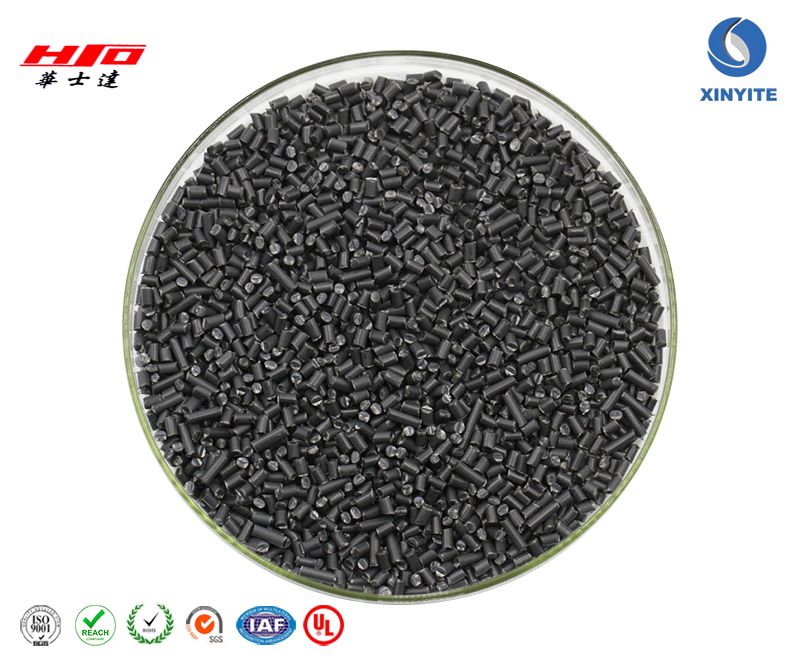

PC Compound Factory

PC has good heat resistance. Generally, when processing ordinary PC materials, its melting temperature can be set between 240 and 300. Even if it stays for a long time, it generally does not decompose. But why do we often see discoloration in the production of some electrical products? This is because the market is now highly competitive. In order to reduce production costs, most manufacturers use PC modified materials or recycled materials to produce low- and medium-grade electrical products. Someuse compound materials such as flame retardants and fillers. Because these materials are mixed, and the plasticization requirements are high, it is difficult to control the process, which causes problems. But these problems can be solved. Our company is very experienced in this area and provides the following solutions to solve these problems:

(1) In terms of process conditions, the melting temperature is mainly considered. Generally, the barrel temperature should be lowered step by step, especially the temperature of the first two sections, and different temperatures are used for different materials. The temperature of the barrel is generally when using PC modified matetiald to produce lighting products. It should be controlled at around 280. Of course, the final selection of the molding temperature must also consider the product shape, size, mold structure, product performance requirements, and other aspects. The second is to fully dry the raw materials to reduce the possibility of trace moisture to the hot melt catalytic cracking. In addition, if the screw speed is too fast, the backpressure is too high, the injection rate is too fast, and the nozzle hole size, runner, and gate size are too small, etc., the melt will generate high shear heat, resulting in melt fracture of the PC. Moreover, it is easy for the gas in the mold cavity to be exhausted in time, resulting in partial burns and darkening of the product.

(2) In terms of equipment, due to the high melt viscosity of PC, the poor fluidity, the high injection pressure required, the strong bonding force with the metallurgy, and the decomposition products have strong corrosiveness to metals, so when selecting processing equipment, small or special Designed, chrome-plated screw, and the plasticizing system does not allow blind spots, dull materials, notches, cracks and so on. Generally speaking, if the process conditions are correct, and the melt is discolored during air injection, this indicates that there is a problem with the plasticizing system, and the plasticizing system needs to be checked one by one.

(3) If there are black spots found in the materials and operation methods as soon as the machine is turned on, this is mostly related to the barrel storage. Therefore, it is necessary to pay attention to the operation method. When the barrel is stocked with PC before starting, the barrel should be cleaned with new materials at the molding temperature 3 to 4 times. If the stored materials are other materials, especially those with poor thermal stability This requires that the temperature can not be increased when the machine is turned on, and the barrel can not be cleaned with PC materials. Only low-temperature materials with good thermal stability such as PS and PE can be used to clean the materials. The temperature of the cylinder is raised to the normal processing temperature of the PC and then washed with the PC material before processing. During the process, if the product needs to be temporarily suspended, the temperature of the barrel must be lowered below 160 to prevent the material from disintegrating and discoloring for too long.

Our company also hason sale, welcome to consult.

在线联系供应商

Other supplier products

| Anti-cold Nylon PA6 Granules | Anti-cold Nylon PA6 Granules Injection Molding Grade, Anti-cold -40°C, Toughening. Main Applications: Automotive parts, Electronic Appliances... | |

| PC/ABS Alloy Granules | Injection molding, PC/ABS Alloy Granules, modified PC/ABS alloy material with high strength, low mold corrosion, low shrinkage, temperature resis... | |

| Flame-Retardant PP Granules Factory | As a, share with you. Flame retardant materials include organic flame-retardant materials and inorganic flame retardant materials. Current flame re... | |

| Halogen Free Flame Retardant Nylon PA66 Granules | Halogen Free Flame Retardant Nylon PA66 Granules Injection Molding Grade, Halogen Free, Flame Retardant, Environmental Friendly. Main Applications:... | |

| PC Compound Factory | PC has good heat resistance. Generally, when processing ordinary PC materials, its melting temperature can be set between 240 and 300. Even if it s... |

Same products

| Ongoing For Sale LDPE Plastic Scrap, LDPE roll, Bale, Lumps | 卖方: I Global Scrap Trading Co. | 欢迎访问 IvoryPharInc.com,这是高品质 LDPE 废料的最重要来源。 自 2004 年成立以来,我们已成为该行业的主要供应商,特别是我们在提供塑料 LDPE 薄膜废料方面的专业知... | |

| Acrylic Scrap For Sale, PMMA Sheet, Offcuts, Trim, Prime Supplier | 卖方: I Global Scrap Trading Co. | IvoryPharInc.com 位于美国,是您出口和供应 PMMA 丙烯酸废料的专门来源,这对全球回收工作做出了巨大贡献。 我们的目标很明确:成为您在塑料废料管理方面的首选合作伙伴,特别强调提... | |

| TPEs from ATPolymer | 卖方: GuangDong Advanced Thermoplastic Polymer Technology Co.,Ltd | Improve flame-retardant performance: It has obtained UL 94V0 grade yellow card certification (1.5... | |

| TPEE from ATPolymer | 卖方: GuangDong Advanced Thermoplastic Polymer Technology Co.,Ltd | TPEE Polymer (TPE Elastomero Termoplastico) is a block copolymer containing polybutylene terephth... | |

| Super Soft TPEs | 卖方: GuangDong Advanced Thermoplastic Polymer Technology Co.,Ltd | The rubber-like functional group is introduced into the material, and when applied to the cable s... |