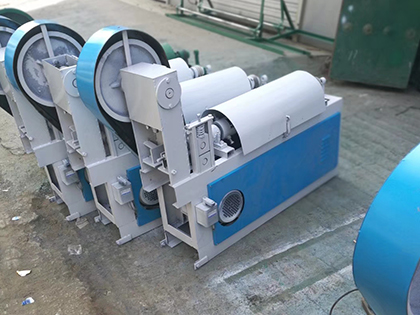

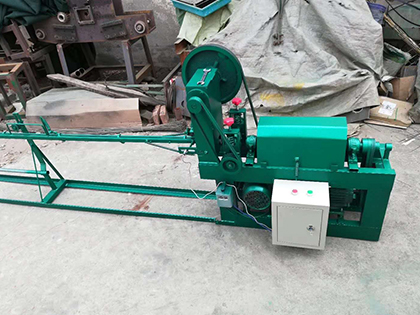

Rebar straightening machine

Rebar straightening machine, also called straight wire machine, straightening wire breaking machine, straightening and cutting machine. It is a kind of straightening equipment. Rebar straightening machine is one of rebar processing machinery. For straightening and cutting steel with a diameter of less than 14 mm

Rebar straightening machine, also called straight wire machine, straightening wire breaking machine, straightening and cutting machine. It is a kind of straightening equipment. Rebar straightening machine is one of the rebar processing machinery. It is used to straighten and cut steel bars with a diameter of less than 14 mm. The cutting length can be customized according to customer requirements. Adjustable cutting of stainless steel wire, aluminum wire, cold drawn wire, plastic-coated steel wire, etc., with uniform cut, small error and good performance.

The operation principle of the steel bar straightening machine: the motor increases the speed through the belt drive, so that the straightening cylinder rotates at a high speed, the steel bar passing through the straightening cylinder is straightened, and the rust on the surface of the steel bar is removed by the straightening die; the motor passes another pair of reduction belts The transmission and gear reduction gearbox, on the one hand, drives the two conveying rollers to draw the steel bars forward, and on the other hand drives the crank wheel to move the hammer head up and down. When the steel bar is adjusted to a predetermined length, the hammer head hits the knife holder to cut the steel bar, and the cut steel bar falls into the receiving frame. Due to the action of the spring, the knife table returns to the original position, completing a cycle. 1. Performance structure: Straightening mechanism-composed of straightening rollers, straightening pressing blocks, and bearing seats at both ends to complete the straightening of the wire. Its power is a motor installed in the lower part of the frame, which drives the straightening shaft to rotate at a high speed through a triangle belt. Feeding mechanism-the pressure roller part is composed of two synchronously running pressure rollers, which are driven by a triangle belt chain to drive a pair of gear pairs, and a pair of coaxial pressure rollers operate synchronously with it. When working, the metal wire runs forward through the groove of the outer circle of the pressure wheel under the action of friction, and the spring speed of the wire can be changed by adjusting the spring of the pressure wheel. The maximum value is equal to the linear velocity of the outer circle of the pressure roller. In the work, the pressure should be adjusted according to the diameter and rigidity of the processed wire to obtain the best straightening effect and production efficiency. Cutting mechanism-The cutting mechanism consists of an eccentric mechanism and a knife holder at one end of the straight wire path to complete the cutting action. The eccentric mechanism is composed of a main shaft, a slider, an eccentric wheel, a rocker arm, and a punch. Its power is driven by a cut-off motor to drive the main shaft to rotate through a triangle belt. Under the action of the eccentric mechanism, the punch reciprocates up and down. When working, when the wire in the straight wire groove reaches a fixed length, the wire quickly pushes the straight wire groove forward under the action of the friction force of the pressure wheel group, and the punch on the top of the cutter head presses the boss at the rear of the block Move to the working stroke of the punch. At this time, the punch is impacted by the punch block to cut the metal wire with a fixed length. At the same time, when the punch block descends, the groove seal twisting iron is pressed underneath it, so that the wire sealing rod rotates around the guide rod, disengages the cut wire in the wire groove, and automatically falls into the wire bucket under the action of gravity, punching When the head goes up, the cutter head also goes up. Under the action of the torsion spring, the thread sealing rod seals the thread groove again. After the wire groove thrust disappears, the straight wire groove returns to the initial state under the action of the tension spring and enters the next cycle. Spinning mechanism——The material carrier is composed of cyclone, material blocking rod, mandrel, base, etc. The wire reel can rotate around the mandrel. After putting the disc-shaped wire, the cyclone can be continuously and automatically fed by the feeding mechanism. material.

Send product request

Other supplier products

| Greenhouse card dip equipment | Greenhouse greenhouse card dipping equipment is used as the profile of plastic film greenhouse film. It is also called film groove, pressure film g... | |

| Chinese Welded wire mesh equipment | The warp and weft mesh machine is nicknamed according to the appearance and characteristics of the product: square grid machine, the name is differ... | |

| 1250 wide expanded steel mesh punching and shearing machine | 1250 wide expanded steel mesh punching and shearing machine | |

| Grassland Net Bullpen Net Machine | The grassland net cattle pen netting machine mainly weaves the surrounding type cattle pen net, and its main feature is to prevent cattle, sheep, h... | |

| Semi-automatic hydraulic crimped wire mesh machine | The semi-automatic hydraulic crimped netting machine is abbreviated as the crimped netting machine, also known as the pre-bent forming netting mach... |

Same products

| Cored Wire | Seller: Henan Frontsteel Silicon Industry Co., Ltd. | Specifications:SiCa/ CaFe/ SiCaBa/ C Cored WireShape:Usage:SteelmakingParticle size:Packaging:Rol... | |

| PVC Dense Wire | Seller: Shijiazhuang Sairui Metal Product Co., Ltd | Small coiled wire, small coiled iron wire Small coiled wire Finely arranged wire Name: Garde... | |

| Galvanized Stranded Wire | Seller: Shijiazhuang Sairui Metal Product Co., Ltd | Product Description Plunged wire: Plunged wire can be called plied binding wire, , which is ma... | |

| Black Annealed Iron Wire | Seller: Shijiazhuang Sairui Metal Product Co., Ltd | Product Description Process:Roll the hot metal billet into a 6.5mm thick steel bar, that is, a... | |

| Galvanized Wire | Seller: Shijiazhuang Sairui Metal Product Co., Ltd | Product Description The galvanizing process is to coat the ordinary iron wire we see daily wit... |