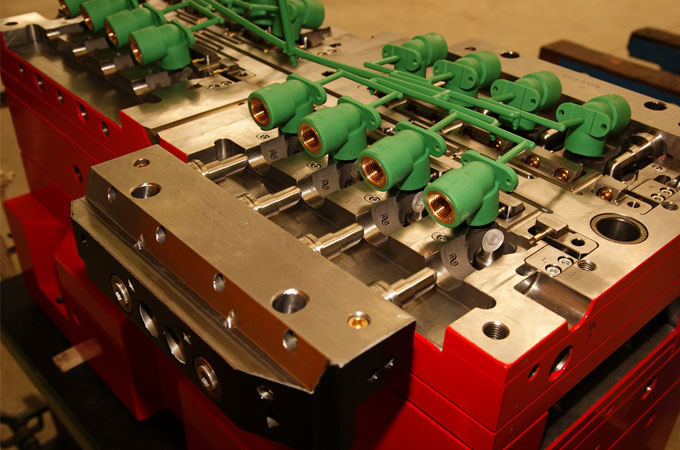

Overmolding & Insert Molding

Founded in 1978, Zhongde is a professional cnc machining companyfocusing on OEM & ODM customized services. Based on 40 years technology deposition, we have developed a one-stop solution from mold designing and rapid prototyping to mass production. Our manufacturing capabilities include plastic injection molding service, compression molding service, CNC machining service, metal stamping service, 3D printing service, custom molding service, overmoulding services, etc.

Zhongde can provide over-molding and insert overmoldingto produce unique multi-material parts. Our production materials range from thermoplastic to elastomer-rubber, as well as metal. We've broken down the differences and similarities between the two processes. Let us help you decide which process is right for your project.

Both over-molding and insert molding processes involve putting two types of materials together to make one part,also named molding over molding. Overmolding is a two steps process that one to create the substrate and one for the oversold that goes on top of it. Insert molding is a slightly faster process as it takes only one step that the two materials are molded at the same time.

Guideline of Overmolding & Insert Molding

Insert molding injectionis a process where a single part is created using two or more different materials in combination. Traditonally, overmolding starts with injection molding a hard plastic resin that has a higher melting point. Once that part is cooled, another material is injection molded over the first part, resulting in a single, finished product.We also offer injection molding threaded inserts.

Insert molding combines metal and plastics into one single part. It allows plastic to bond to insert pieces, mostly brass or stainless steel metal component, which go inside a mold cavity. There are many options for insert that can be placed into the mold. A few of examples are warming labels, threaded bushings, wires, batteries, etc.

Size of Overmolding & Insert Molding

Below table shows the size of Overmolding & Insert Molding parts we usually make. If you need a larger size, we can also help you achieve it.

|

Size |

Metric |

Inch |

|

Length |

2500 |

|

|

Width |

2000 |

|

|

Height |

1500 |

59 |

Available Material of Overmolding And Insert MoldingIn addition to the general materials listed below, Zhongde can also modify the materials according to the special needs of customers. Our professional engineers will adjust the raw material formula to meet the unique conditions of use.

Overmolding & Insert Molding Plastic

ABS | Acrylonitrile Butadiene Styrene

PA 6 | Polyamide 6, Nylon 6

PA 6/6 | Polyamide 6/6, Nylon 6/6

POM | Acetal Polyoxymethylene, Delrin

PP | Polypropylene

PE | Polyethylene

LDPE | Low-Density Polyethylene

HDPE | High-Density Polyethylene

UHMWPE |Ultrahigh Molecular Weight Polyethylene

PTFE | Polytetrafluoroethylene

PEEK | Polyether Ether Ketone

PC | Polycarbonate

PMMA | Polymethyl Methacrylate, Acrylic

PS | Polystyrene

PVC | Polyvinyl Chloride (Shore D)

PU | Polyurethane

Overmolding & Insert molding Rubber

NR | Natural Rubber

NBR | Nitrile Rubber

SBR | Styrene-butadiene Rubber

HNBR | Hydrogenated Nitrile

CR | Neoprene Rubber

VMQ | Silicone

LSR | Liquid Silicone Rubber

FVMQ | Fluorosilicone

FKM | Fluorocarbon

FFKM | Perfluorocarbon Rubber

EPDM | Ethylene-Propylene Diene Monomer Rubber

IR | Polyisoprene Rubber

IIR | Butyl Rubber

Additives of Overmolding & Insert Molding

|

Name |

Description |

|

UV absorbers |

Absorb UV radiation, slowing down the degradation of the material when used outdoors. |

|

Flame retardants |

Prevent ignition and inhibits spread of fire. |

|

Plasticizers |

Increase flexibility and promotes plasticity, reducing brittleness of the material. |

|

Colorants |

Used to color plastics. |

|

Carbon fibers |

Increase strength, toughness, and rigidity of the material at the expense of making the material more brittle. |

|

Glass fibers |

Increase strength, toughness, and rigidity of the material at the expense of making the material more brittle. It is more flexible than carbon fibers. |

Surface Finishing of Overmolding & Insert Molding

|

Name |

Description |

|

Glossy |

The mold is smoothed and then polished with a diamond buff, resulting in parts with a mirror-like finish. |

|

Semi-gloss |

The mold is smoothed with fine grit sandpaper, resulting in parts with a fine surface finish. |

|

Matte |

The mold is smoothed using fine stone powder, removing all machining marks. |

|

Textured finish |

The mold is first smoothed with fine stone powder and then sandblasted, resulting in a textured surface. |

|

As-machined finish |

The mold is finished to the machinist's discretion. Tool marks may be visible. |

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Custom Rubber Parts | Injection Molding | Compression Molding Cost-effective and high quality products Size from small to large, structure from simple to complex Get a ... | |

| China Custom CNC Machining Parts | Zhongde provides professional and reliable custom injection molding services, and makes all the molds in-house. Our completed production line and v... | |

| Plastic CNC Machining Parts | The following are some of the china cnc machining plastic partscompany has made through custom cnc plastic partsand turning services. They are n... | |

| Rubber Bonding Metal Parts | The following are some of the rubber parts we have made. They are only for displaying our products range and shape. but not for sale. Upload drawin... | |

| Metal CNC Machining Parts | The following are some of the plastic bonding metal parts we have made. They are only for displaying our products range and shape. but not for sale... |