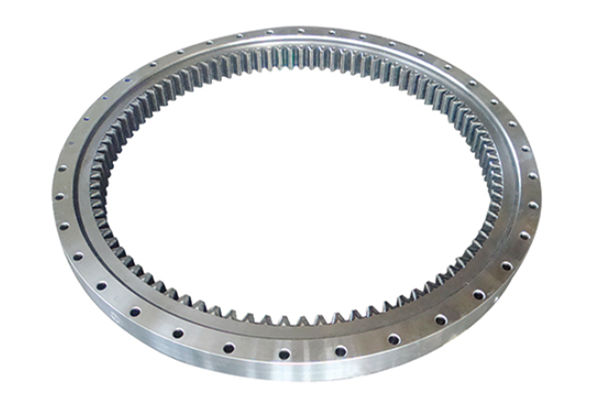

Single-Row Ball Type Slewing Ring

Fuyong Intelligent is one of China's leading slewing bearing manufacturers. With a wide range of dimensions and designs, our worm slew drives and slewing ring are popular around the world. The slew drives and slewing bearing are widely used in engineering machinery, coal mining machinery, fire equipment, industrial robots, photovoltaic power trackers, aviation and military defense. We have 18 independent intellectual property rights patents. Our slewing ring driveand slew drive bearings have passed ISO9000:2008 quality management system certification and EU export CE certification. We promise professional production and excellent quality.

The SingleRow Ball Slewing Bearinghave four points with one row. They could bear axial load, radial load and tilting moment at the same time. And they are composed of two seat rings, which design in compact structure and light weight, steel ball contact with the circular raceway at four points. There are three types of this kind of single row 4 points contact ball slewing ring: without gear bearing (non tooth), external gear bearing (external tooth), and Internal gear bearing (internal tooth).

|

01 JB/T 2300-1999 Basic data of standard series 01. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Basic Size |

Configuration Size |

Mounting Size |

Structural Size |

Gear Data |

Outer Gear Data |

Inner Gear Data |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

NoTeeth |

Outer Teeth |

Inner Teeth |

D |

d |

H |

D1 |

D2 |

n |

Bolt Hole |

Screw Hole |

n1 |

H1 |

h |

b |

x |

m |

da |

Z |

da |

Z |

||||||||||||||||||||||||||||||||||||||||||||||||

|

O |

1,2,3 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Do |

Do |

Do |

φ |

d1 |

T |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1 |

— |

280 |

120 |

60 |

248 |

152 |

12 |

16 |

M14 |

28 |

2 |

50 |

10 |

40 |

0 |

3 |

300 |

98 |

— |

— |

||||||||||||||||||||||||||||||||||||||||||||||||

|

2 |

— |

304 |

144 |

60 |

272 |

176 |

12 |

16 |

M14 |

28 |

2 |

50 |

10 |

40 |

0 |

3 |

321 |

105 |

— |

— |

||||||||||||||||||||||||||||||||||||||||||||||||

|

3 |

— |

330 |

170 |

60 |

298 |

202 |

18 |

16 |

M14 |

28 |

2 |

50 |

10 |

40 |

0 |

4 |

352 |

86 |

— |

— |

||||||||||||||||||||||||||||||||||||||||||||||||

|

4 |

— |

360 |

200 |

60 |

328 |

232 |

18 |

16 |

M14 |

28 |

2 |

50 |

10 |

40 |

0 |

4 |

384 |

94 |

— |

— |

||||||||||||||||||||||||||||||||||||||||||||||||

|

5 |

408 |

222 |

70 |

372 |

258 |

20 |

18 |

M16 |

32 |

2 |

60 |

10 |

50 |

0 |

5 |

435 |

85 |

190 |

40 |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

6 |

448 |

262 |

70 |

412 |

298 |

20 |

18 |

M16 |

32 |

2 |

60 |

10 |

50 |

0 |

5 |

475 |

93 |

235 |

49 |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

7 |

493 |

307 |

70 |

457 |

343 |

24 |

18 |

M16 |

32 |

2 |

60 |

10 |

50 |

0 |

6 |

528 |

86 |

276 |

48 |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

8 |

543 |

357 |

70 |

507 |

393 |

24 |

18 |

M16 |

32 |

2 |

60 |

10 |

50 |

0 |

6 |

576 |

94 |

324 |

56 |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

9 |

602 |

398 |

80 |

566 |

434 |

20 |

18 |

M16 |

32 |

4 |

70 |

10 |

60 |

5 |

629 |

123 |

367 |

74 |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

6 |

102 |

62 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

10 |

662 |

458 |

80 |

626 |

494 |

20 |

18 |

M16 |

32 |

4 |

70 |

10 |

60 |

5 |

689 |

135 |

427 |

86 |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

6 |

112 |

72 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

11 |

732 |

528 |

80 |

696 |

564 |

24 |

18 |

M16 |

32 |

4 |

70 |

10 |

60 |

6 |

126 |

83 |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

8 |

94 |

62 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

12 |

812 |

608 |

80 |

776 |

644 |

24 |

18 |

M16 |

32 |

4 |

70 |

10 |

60 |

6 |

139 |

96 |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

8 |

104 |

72 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

13 |

922 |

678 |

100 |

878 |

722 |

30 |

22 |

M20 |

40 |

6 |

90 |

10 |

80 |

8 |

118 |

80 |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

10 |

968 |

94 |

634 |

64 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

14 |

1022 |

778 |

100 |

978 |

822 |

30 |

22 |

M20 |

40 |

6 |

90 |

10 |

80 |

8 |

130 |

93 |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

10 |

1068 |

104 |

734 |

74 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

15 |

1122 |

878 |

100 |

1078 |

922 |

36 |

22 |

M20 |

40 |

6 |

90 |

10 |

80 |

10 |

1188 |

116 |

824 |

83 |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

12 |

96 |

69 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

16 |

1242 |

998 |

100 |

1198 |

1042 |

36 |

22 |

M20 |

40 |

6 |

90 |

10 |

80 |

10 |

1298 |

127 |

944 |

95 |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

12 |

106 |

79 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

17 |

1390 |

1110 |

110 |

1337 |

1163 |

40 |

26 |

M24 |

48 |

5 |

100 |

10 |

90 |

12 |

118 |

88 |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

14 |

101 |

75 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

18 |

1540 |

1260 |

110 |

1487 |

1313 |

40 |

26 |

M24 |

48 |

5 |

100 |

10 |

90 |

12 |

131 |

100 |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

14 |

112 |

86 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

19 |

1740 |

1460 |

110 |

1687 |

1513 |

45 |

26 |

M24 |

48 |

5 |

100 |

10 |

90 |

14 |

127 |

100 |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

16 |

111 |

87 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

20 |

1940 |

1660 |

110 |

1887 |

1713 |

45 |

26 |

M24 |

48 |

5 |

100 |

10 |

90 |

14 |

141 |

113 |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

16 |

123 |

99 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

21 |

2178 |

1825 |

144 |

2110 |

1891 |

48 |

33 |

M30 |

60 |

8 |

132 |

12 |

120 |

16 |

139 |

109 |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

18 |

123 |

97 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

22 |

2418 |

2065 |

144 |

2350 |

2131 |

48 |

33 |

M30 |

60 |

8 |

132 |

12 |

120 |

16 |

153 |

125 |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

18 |

136 |

111 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

23 |

2678 |

2325 |

144 |

2610 |

2391 |

56 |

33 |

M30 |

60 |

8 |

132 |

12 |

120 |

18 |

151 |

125 |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

20 |

2776 |

136 |

2228 |

112 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

24 |

2978 |

2625 |

144 |

2910 |

2691 |

56 |

33 |

M30 |

60 |

8 |

132 |

12 |

120 |

18 |

168 |

141 |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

20 |

3076 |

151 |

2528 |

127 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

25 |

3376 |

2922 |

174 |

3686 |

3014 |

56 |

45 |

M42 |

84 |

8 |

162 |

12 |

150 |

20 |

3476 |

171 |

2828 |

142 |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

22 |

155 |

129 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

26 |

3776 |

3322 |

174 |

3686 |

3414 |

56 |

45 |

M42 |

84 |

8 |

162 |

12 |

150 |

20 |

3876 |

191 |

3228 |

162 |

||||||||||||||||||||||||||||||||||||||||||||||||||

|

22 |

174 |

147 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

27 |

4226 |

3772 |

174 |

4136 |

3864 |

60 |

45 |

M42 |

84 |

10 |

162 |

12 |

150 |

22 |

194 |

167 |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

25 |

4345 |

171 |

3660 |

147 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

JB/T10839-2008(JJ 36.1-91)Basic data of standard series Q. ( Recommendation) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Basic Size |

Configuration Size |

Mounting Size |

Structural Size |

Gear Data |

Outer Gear Data |

Inner Gear Data |

Weight |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Outer Teeth |

Inner Teeth |

H |

D1 |

D2 |

n |

Bolt Hole |

Screw Hole |

n1 |

H1 |

h |

b |

m |

X=-0.5 |

X=+0.5 |

kg Outer gear |

kg Inner gear |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Do |

A |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

D |

d |

D |

d |

φ |

d1 |

T |

da |

Z |

da |

Z |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1 |

406 |

222 |

408 |

224 |

60 |

370 |

260 |

10 |

17 |

M16 |

24 |

2 |

50 |

10 |

40 |

3 |

423 |

140 |

207 |

70 |

35 |

34 |

||||||||||||||||||||||||||||||||||||||||||||||

|

4 |

428 |

106 |

200 |

51 |

36 |

35 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2 |

446 |

262 |

448 |

264 |

60 |

410 |

300 |

10 |

17 |

M16 |

24 |

2 |

50 |

10 |

40 |

3 |

462 |

153 |

246 |

84 |

40 |

39 |

||||||||||||||||||||||||||||||||||||||||||||||

|

4 |

468 |

116 |

240 |

61 |

41 |

40 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

3 |

490 |

307 |

493 |

310 |

60 |

455 |

345 |

12 |

17 |

M16 |

24 |

2 |

50 |

10 |

40 |

4 |

512 |

127 |

288 |

73 |

45 |

44 |

||||||||||||||||||||||||||||||||||||||||||||||

|

5 |

520 |

103 |

280 |

57 |

47 |

46 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

4 |

540 |

357 |

543 |

360 |

60 |

505 |

395 |

12 |

17 |

M16 |

24 |

2 |

50 |

10 |

40 |

4 |

564 |

140 |

336 |

85 |

51 |

50 |

||||||||||||||||||||||||||||||||||||||||||||||

|

5 |

570 |

113 |

330 |

67 |

43 |

52 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

5 |

590 |

407 |

593 |

410 |

60 |

555 |

445 |

14 |

17 |

M16 |

24 |

2 |

50 |

10 |

40 |

5 |

615 |

122 |

385 |

78 |

56 |

55 |

||||||||||||||||||||||||||||||||||||||||||||||

|

6 |

624 |

103 |

378 |

64 |

58 |

57 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

6 |

654 |

464 |

656 |

468 |

70 |

618 |

502 |

14 |

17 |

M16 |

30 |

2 |

60 |

10 |

50 |

4 |

680 |

169 |

440 |

111 |

78 |

76 |

||||||||||||||||||||||||||||||||||||||||||||||

|

5 |

685 |

136 |

435 |

88 |

79 |

77 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

7 |

724 |

534 |

726 |

538 |

70 |

688 |

572 |

16 |

17 |

M16 |

30 |

2 |

60 |

10 |

50 |

4 |

748 |

186 |

512 |

129 |

86 |

84 |

||||||||||||||||||||||||||||||||||||||||||||||

|

5 |

755 |

150 |

505 |

102 |

88 |

86 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

8 |

804 |

614 |

806 |

618 |

70 |

768 |

652 |

18 |

17 |

M16 |

30 |

2 |

60 |

10 |

50 |

5 |

835 |

166 |

585 |

118 |

99 |

97 |

||||||||||||||||||||||||||||||||||||||||||||||

|

6 |

840 |

139 |

582 |

98 |

101 |

97 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

9 |

894 |

704 |

896 |

708 |

70 |

858 |

742 |

20 |

17 |

M16 |

30 |

2 |

60 |

10 |

50 |

6 |

930 |

154 |

672 |

113 |

114 |

110 |

||||||||||||||||||||||||||||||||||||||||||||||

|

8 |

936 |

116 |

664 |

84 |

114 |

111 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

10 |

904 |

692 |

908 |

694 |

78 |

864 |

736 |

18 |

22 |

M20 |

36 |

2 |

68 |

10 |

58 |

6 |

942 |

156 |

654 |

110 |

143 |

142 |

||||||||||||||||||||||||||||||||||||||||||||||

|

8 |

952 |

118 |

648 |

82 |

147 |

142 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

11 |

1004 |

792 |

1008 |

794 |

78 |

964 |

836 |

20 |

22 |

M20 |

36 |

2 |

68 |

10 |

58 |

8 |

1048 |

130 |

744 |

94 |

162 |

163 |

||||||||||||||||||||||||||||||||||||||||||||||

|

10 |

1060 |

105 |

740 |

75 |

168 |

162 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

12 |

1104 |

892 |

1108 |

894 |

78 |

1064 |

936 |

24 |

22 |

M20 |

36 |

2 |

68 |

10 |

58 |

8 |

1152 |

143 |

848 |

107 |

182 |

178 |

||||||||||||||||||||||||||||||||||||||||||||||

|

10 |

1160 |

115 |

840 |

85 |

185 |

179 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

13 |

1120 |

876 |

1124 |

880 |

90 |

1074 |

926 |

24 |

24 |

M22 |

40 |

2 |

80 |

10 |

70 |

8 |

1160 |

144 |

832 |

105 |

227 |

230 |

||||||||||||||||||||||||||||||||||||||||||||||

|

10 |

1170 |

116 |

830 |

84 |

232 |

227 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

14 |

1240 |

996 |

1244 |

1000 |

90 |

1194 |

1046 |

28 |

24 |

M22 |

40 |

4 |

80 |

10 |

70 |

10 |

1300 |

129 |

940 |

95 |

272 |

263 |

||||||||||||||||||||||||||||||||||||||||||||||

|

12 |

1308 |

108 |

936 |

79 |

275 |

262 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

15 |

1370 |

1126 |

1374 |

1130 |

90 |

1324 |

1176 |

32 |

24 |

M22 |

40 |

4 |

80 |

10 |

70 |

10 |

1430 |

142 |

1070 |

108 |

302 |

294 |

||||||||||||||||||||||||||||||||||||||||||||||

|

12 |

1440 |

119 |

1068 |

90 |

309 |

290 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

16 |

1520 |

1276 |

1524 |

1280 |

90 |

1474 |

1326 |

36 |

24 |

M22 |

40 |

4 |

80 |

10 |

70 |

12 |

1584 |

131 |

1212 |

102 |

337 |

333 |

||||||||||||||||||||||||||||||||||||||||||||||

|

14 |

1596 |

113 |

1204 |

87 |

347 |

336 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

17 |

1390 |

1108 |

1394 |

1110 |

102 |

1336 |

1164 |

32 |

26 |

M24 |

45 |

4 |

90 |

12 |

80 |

10 |

1450 |

144 |

1050 |

106 |

396 |

388 |

||||||||||||||||||||||||||||||||||||||||||||||

|

12 |

1452 |

120 |

1044 |

88 |

392 |

388 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

18 |

1540 |

1258 |

1544 |

1260 |

102 |

1486 |

1314 |

36 |

26 |

M24 |

45 |

4 |

90 |

12 |

80 |

12 |

1608 |

133 |

1188 |

100 |

448 |

444 |

||||||||||||||||||||||||||||||||||||||||||||||

|

14 |

1610 |

114 |

1190 |

86 |

443 |

434 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

19 |

1740 |

1458 |

1744 |

1460 |

102 |

1686 |

1514 |

40 |

26 |

M24 |

45 |

4 |

90 |

12 |

80 |

12 |

1812 |

150 |

1392 |

117 |

528 |

509 |

||||||||||||||||||||||||||||||||||||||||||||||

|

14 |

1820 |

129 |

1386 |

100 |

534 |

511 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

20 |

1940 |

1658 |

1944 |

1660 |

102 |

1886 |

1714 |

44 |

26 |

M24 |

45 |

4 |

90 |

12 |

80 |

14 |

2016 |

143 |

1582 |

114 |

583 |

576 |

||||||||||||||||||||||||||||||||||||||||||||||

|

16 |

2032 |

126 |

1568 |

99 |

607 |

591 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

21 |

1762 |

1434 |

1766 |

1438 |

124 |

1704 |

1496 |

40 |

30 |

M27 |

50 |

4 |

112 |

12 |

100 |

12 |

1824 |

151 |

1368 |

115 |

714 |

714 |

||||||||||||||||||||||||||||||||||||||||||||||

|

14 |

1834 |

130 |

1358 |

98 |

727 |

723 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

22 |

1964 |

1634 |

1966 |

1638 |

124 |

1904 |

1696 |

44 |

30 |

M27 |

50 |

4 |

112 |

12 |

100 |

14 |

2044 |

145 |

1568 |

113 |

845 |

794 |

||||||||||||||||||||||||||||||||||||||||||||||

|

16 |

2048 |

127 |

1552 |

98 |

843 |

818 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

23 |

2162 |

1834 |

2166 |

1842 |

124 |

2104 |

1896 |

48 |

30 |

M27 |

50 |

6 |

112 |

12 |

100 |

16 |

2240 |

139 |

1760 |

111 |

912 |

891 |

||||||||||||||||||||||||||||||||||||||||||||||

|

18 |

2250 |

124 |

1746 |

98 |

927 |

913 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

24 |

2402 |

2074 |

2406 |

2078 |

124 |

2344 |

2136 |

54 |

30 |

M27 |

50 |

6 |

112 |

12 |

100 |

16 |

2480 |

154 |

1984 |

125 |

1020 |

1044 |

||||||||||||||||||||||||||||||||||||||||||||||

|

18 |

2502 |

138 |

1980 |

111 |

1078 |

1041 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

25 |

2662 |

2334 |

2666 |

2342 |

124 |

2604 |

2396 |

60 |

30 |

M27 |

50 |

6 |

112 |

12 |

100 |

18 |

2754 |

152 <Отправить запрос, связаться с поставщикомДругие товары поставщика

Похожие товары

Loading

| ||||||||||||||||||||||||||||||||||||||||||||||||||