LINEAR SORTER

Lisen Automation group is a national high-tech Material handling expertsthat provides integrated intelligent logistics solution, application technology and equipment, is a professional supporting partner of product manufacturing and circulation enterprises. After near 20 years of development, Lisen Automation has become a famous brand in the industry in China. It provide food processing automation and chemical automation,etc.

Line sorter: the conveyor surface is composed of metal sheets, and there is a narrow belt on each metal sheet, which can move laterally along the metal sheet. When parcel arrives designated chute position, control system controls guide rob to action to make belt move towards side of conveyor, motivating the parcel and realizing the parcel sorting.

Linear design, compact structure, small footprint, much space saving.

Wide application range, applicable for various goods with different sizes, shapes and natures, lower than 10kg, including very small and thin ones.

Extremely low running noise. The whole equipment average noise is lower than 70dB.

Low operation and maintenance cost, easy and safe to operate.

Specification of Linear Sorter

|

Parameters of twin-carrier linear sorter |

|||||

|

Item name |

Parameter |

Remark |

|||

|

1 |

Carrier pitch |

500MM |

|||

|

2 |

Carrier size |

424*700MM |

|||

|

3 |

Sorter speed |

||||

|

4 |

Induction method |

Manual, semi-automatic, fully automatic |

Automatic induction(Min. weight 100g, Min. size 150*100*10mm) |

||

|

4 |

Theoretical efficiency |

10800pcs/H(1.5M/S) |

Loop line speed*3600seconds/0.6 |

||

|

5 |

Sorting accuracy |

≥99.99% |

|||

|

6 |

Barcode reading rate |

≥99% |

|||

|

7 |

Chute width |

750mm |

Width adjusted according to parcel size and loop line speed |

||

|

8 |

Parcel size |

|

Support two carriers for one parcel loading(max. parcel size 800*600mm) |

||

|

9 |

Parcel weight |

20g~30kg |

Support two carriers for one parcel loading, max. parcel weight 50kg. |

||

|

Main parts brand |

|||||

|

Main parts |

Brand |

Remark |

|||

|

1 |

Carrier belt |

SIEGLING、HIGHTEN |

|||

|

2 |

Electric roller |

M&D/WIN Roller |

|||

|

3 |

Linear motor |

SEW synchronous linear motor |

|||

|

4 |

Barcode reader |

Italy Datalogic/Germany SICK/US Cognex/HIKVISION |

|||

|

5 |

Grayscale test |

US BANNER/Italy Datalogic |

|||

|

6 |

PLC |

Siemens |

|||

|

7 |

Sliding contact line |

Germany VAHLE |

|||

|

8 |

Track |

LISEN |

Tailored aluminum extrusion /sheet metal track |

||

Advantages of Linear Sorter

Sorting efficiency 10800pcs per hour.

Low operation and maintenance cost, low energy consumption, short ROI cycle.

Simple to operate, easy to use.

Low running noise, average noise less than 70dBA(one meter distance), improving working environment.

Manual, semi-automatic, fully automatic 3 induction methods for choosing.

Main drive adopts magnetic levitation structure (synchronous linear motor/asynchronous linear motor).

Automatic deviation rectification, multilateral and beyond edge detection functions.

Small footprint, applicable in narrow sites.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

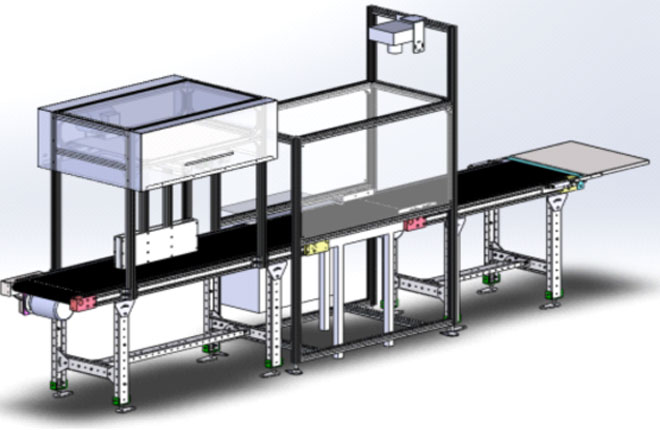

| AUTOMATED SCANNING AND WEIGHING LINE(DWS) | Four indicators: Small footprint, wide application range, labor force reducing, high efficiency Automated scanning and weighing line: it's used at... | |

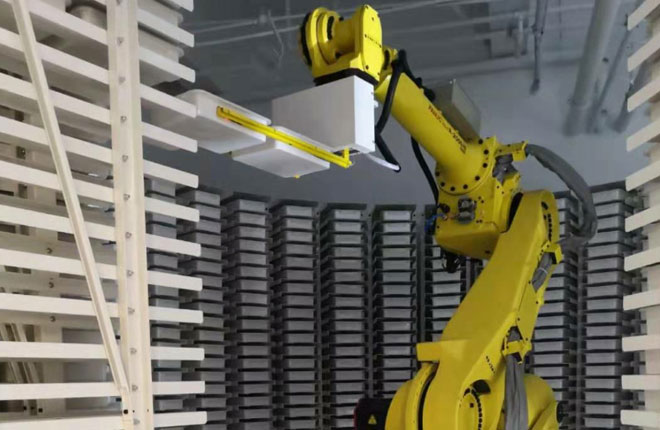

| ROBOTIC PICKING SYSTEM | Pick and place vision system: it consists of 6 major modules, including robot order picking system, robot piece picking system, robot de-palletizin... | |

| AUTOMATED PUT WALL | LISEN Automation Rabbit Sorter, or called putwall sorter, is a highly scalable, configurable, and cost-effective logistics sorting system, featurin... | |

| AS/RS (AUTOMATED STORAGE AND RETRIEVAL SYSTEM) | The asrs or automatic storage retrieval systemis a software with independent intellectual property for automated warehouse management and schedulin... | |

| RGV-RAIL GUIDED VEHICLE | 4 indicators: small footprint, wide application range, manpower saving, high efficiency RGV: RGV is the abbreviation of Rail Guided Vehicle, whi... |