TURNING INSERT

Betalent carbide offers standard carbide turning insertsin different shapes, different application. To select a proper turning insert, you need to consider insert shape, it is the first important factor which relates to the main deflection angle of the insert, the sharp angle of the insert and the effective cutting edges, selection of insert shape is depending on the shape of the machining part. However, it is suggested that choose the insert with larger tip angle if can meet your needs because the higher the tip strength is. Only when complex profile, groove excavation and downhill profile you choose the small-tip-angle insert for the less interference phenomenon, the other factor including the price and the operation convenient.

According to the shape, inserts can be divided into different series. The following seven shapes are the most often used turning inserts chart.

V Series

C Series

D Series

R Series

T Series

S Series

Relate Turning Insert Products

Milling Insert Milling Insert

Carbide Inserts Related FAQs Carbide Inserts Related FAQs

Threading Insert Threading Insert

Xiamen Betalent Carbide Co., Ltd isa professional turning insert manufacturer, we provide hard turning inserts, turning inserts for titanium, lathe cutting inserts, cnc turning inserts, full size carbide turning tools, cemented carbide products, carbide cutte, etc.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| TWIST DRILL BIT | Betalent twist drill bits are manufactured by Walter 5-axil grinding machine base on submicron grain size tungsten carbide rods, which enable the e... | |

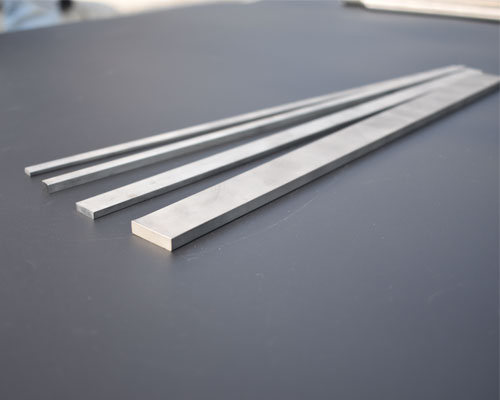

| CARBIDE STRIPS | Carbide flatsare referring the rectangular tungsten carbide rod, also known as tungsten carbide strips.It is produced by the same way as carbide ro... | |

| TUBE DRAWING DIE BLANK | Betalent carbide offers carbide grades special for tube drawing dieand inner plug, all tube drawing dies, and plugs are customized according to dr... | |

| CENTER DRILL BIT | Center finderdrill bitis a common tool in machining, which plays an important role in actual production. The first application of center drill was ... | |

| ROUGHING END MILL | ROUGHING END MILL There are four carbide grades applied to general flat end mills: BT45, for milling materials of which hardness range from HRC4... |