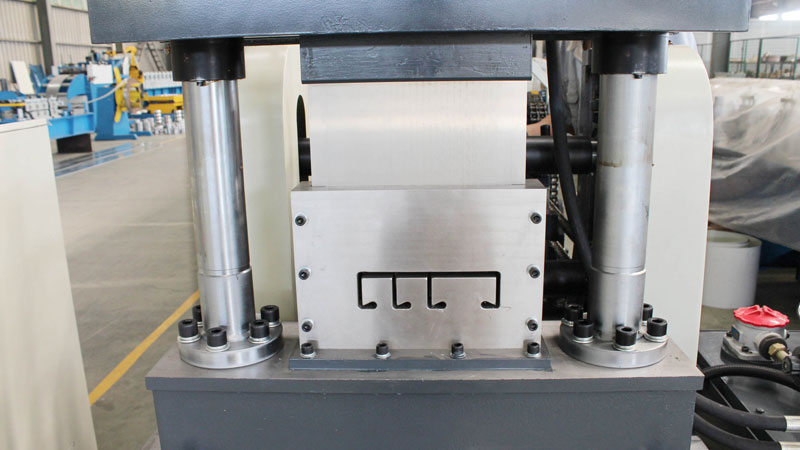

High Frequency ERW Pipe Mill Line

High-Frequency ERW Pipe Mill Lineis mainly used for making ERW welded steel pipes. ERW is short for Electric Resistance Welding. At present, ERW pipe occupies a decisive position in the field of conveying pipe in the world. Ourhigh-frequency ERW pipe millis featured with the advantages of high production efficiency, low cost, material saving, and easy automation.

Main Technical Parameters ofERW Pipe Mill For Sale(For reference only, will be as requests)

A: suitable strip coils

Alloy Steel Coil; API5L X42-X80

(For reference only, will be as requests)

Length: 6m-12m

Length tolerance:+/-3mm

Production speed: 20-120m/min

Direction: Left to right or right to left from operator's side(as requests by customer)

Capacity: 10,000 ton/year-180, 000 ton/year

Electricity input power: 50kW-1400kW

Foundation: 40m–400m (length) x 3.8m-40m (width)

Weight: About 30ton–300ton.

Operator: 6-8 people (as size requests)

Technical Parameters ofERW Pipe Mill for Sale

|

Model |

Round pipe |

Square pipe |

Thickness |

Speed |

|

mm |

mm |

mm |

m/min |

|

|

RFT-12 |

Ф4-Ф12 |

120 |

||

|

RFT-16 |

Ф6-Ф16 |

120 |

||

|

RFT-20 |

Ф8-Ф20 |

6x6-15x15 |

120 |

|

|

RFT-25 |

Ф10-Ф25 |

7x7-19x19 |

120 |

|

|

RFT-32 |

Ф12-Ф32 |

9x9-25x25 |

120 |

|

|

RFT-50 |

Ф20-Ф50 |

15x15-39x39 |

120 |

|

|

RFT-76 |

Ф32-Ф76 |

25x25-59x59 |

120 |

|

|

RFT-89 |

Ф42-Ф89 |

35x35-70x70 |

110 |

|

|

RFT-114 |

Ф48-Ф114 |

40x40-90x90 |

70 |

|

|

RFT-140 |

Ф60-Ф140 |

50x50-110x110 |

60 |

|

|

RFT-165 |

Ф76-Ф165 |

60x60-130x130 |

55 |

|

|

RFT-219 |

Ф89-Ф219 |

70x70-170x170 |

50 |

|

|

RFT-273 |

Ф114-Ф273 |

90x90-210x210 |

45 |

|

|

RFT-325 |

Ф140-Ф325 |

110x110-250x250 |

40 |

|

|

RFT-377 |

Ф165-Ф377 |

130x130-280x280 |

35 |

|

|

RFT-406 |

Ф219-Ф406 |

170x170-330x330 |

30 |

|

|

RFT-508 |

Ф273-Ф508 |

210x210-400x400 |

25 |

|

|

RFT-660 |

Ф325-Ф660 |

250x250-500x500 |

20 |

|

|

RFT-720 |

Ф355-Ф720 |

300x300-600x600 |

20 |

Working Flow of high frequency pipe millLine

What is ERW Pipe?

Regarding its classification, ERW pipes can be roughly divided into 2 forms of ERW AC welding steel pipes and ERW DC welded steel pipes. And according to a different frequency, ERW seam-welded tubes can also be classified into low-frequency welding pipes, medium frequency welding pipes, and supercurrent welding pipes. Normally, high-frequency welding is mainly used in the production of thin-walled pipes or ordinary wall-thick ERW pipes, and high-frequency soldering is also divided into contact welding and induction welding. Currently, the ERW pipe is mainly used in tap water engineering, the petrochemical industry, the chemical industry, the electricity industry, agricultural irrigation, and urban construction. Concerning the significance of the ERW pipes in various industries, it is then of great importance to choose reliable ERW pipe manufacturing machine. And Hangzhou Roll Forming Technology can help you with that!

Finished ERW Pipe Mills by ERW Tube MillLine

Specifications of ERW Pipe Mill for Sale

|

Machine Condition |

Fully New, A Grade quality |

|

Size |

As requests |

|

Power Supply |

220V/380V/415V/460V/480V, 50/60Hz, 3P (as requests) |

|

Equipment Weight |

About 30ton-300ton |

|

Dimension |

40m–400m (length) x 3.8m-40m (width) |

|

LOADING SIZE |

Normally need 4-30 x 40' containers |

|

Equipment Color |

normally Blue/Green/White, or as requests |

|

Place of Origin |

Zhejiang, China (Mainland) |

|

Packing |

Standard and careful export packing |

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Solar Photovoltaic Support Rolling Machine | SOLAR PHOTOVOLTAIC SUPPORT ROLLING MACHINE Double-in-roll c-shaped steel photovoltaic bracket is mainly applicable to the ground photovoltaic po... | |

| Semi-Auto C/Z Purlin Roll Forming Machine | Semi-Automatic cz purlin machinefor Sale uses the same set of equipment to produce various specifications of C/Z purlin through semi-automatic simp... | |

| High Speed Roofing Tile Making Machine | The high-speed metal roof tile machine is for continuously roll forming and pressing step tilessheets. Thesteplength of this series can be set up a... | |

| Downspout Roll Forming Machine | Downspout roll forming machine, also known as downpipe roll forming machine, downspout elbow machine, roof leader, downcomer, or gutter downpipe ma... | |

| Fully Automatic CZ Purlin Roll Forming Machine | The fully automatic C/Z steel integrated machine is also called the C/Z interchange molding machine, and C and Z interchange purlin machine. The fu... |

Похожие товары

| Common Rail injector control valve F00V C01 365 & Common Rail injector control valve F00V C01 368 | Продавец: zhonglutong | Common Rail injector control valve F00V C01 365 Common Rail injector control valve F00V C01 368 C... | |

| Common Rail injector control valve F00V C01 362 & Common Rail injector control valve F00V C01 363 | Продавец: zhonglutong | Common Rail injector control valve F00V C01 362 Common Rail injector control valve F00V C01 363 C... | |

| Common Rail injector control valve F00V C01 358 & Common Rail injector control valve F00V C01 359 | Продавец: zhonglutong | Common Rail injector control valve F00V C01 358 Common Rail injector control valve F00V C01 359 C... | |

| Common Rail injector control valve F00V C01 355 & Common Rail injector control valve F00V C01 356 | Продавец: zhonglutong | Common Rail injector control valve F00V C01 355 Common Rail injector control valve F00V C01 356 C... | |

| Common Rail injector control valve F00V C01 352 & Common Rail injector control valve F00V C01 353 | Продавец: zhonglutong | Common Rail injector control valve F00V C01 352 Common Rail injector control valve F00V C01 353 C... |