Turntable linkage high-speed manipulator

Yiheda automation is one of the best industrial assembly automation companies, as an expert custom automation company, specializes in designing and manufacturing the custom automation solution to customers.

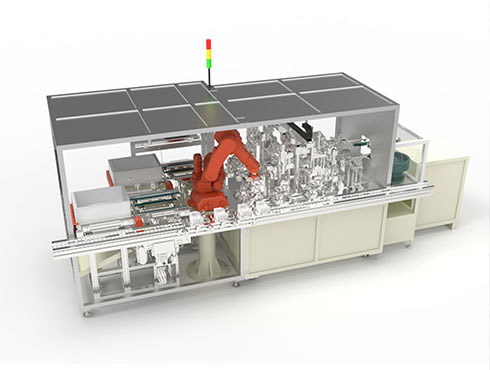

Machine introduction of Turntable 90 degree linkagehigh-speed manipulator

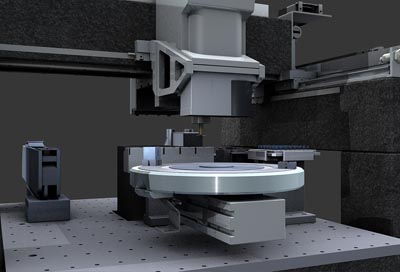

Driven by two sets of servo motor and screw rod, the manipulator can move in X-axis and Z-axis direction. One X-axis action plus two z-axis actions are a cycle, the cycle time is 1.2s, which guarantee the speed, stability and accuracy of the manipulator, and can replace the traditional pneumatic manipulator.

Machine features of high speed turntablemanipulator

Driven by two sets of independent three-phase servo motor.

With high accuracy screw rod.

Simplified the traditional complex control system input.

The remove, lift and press-fitting module are easy to change and flexible.

With compact structure and easy to be integrated.

Standard design, short delivery time and low cost.

Replace the traditional pneumatic manipulator with indexing table.

Cycle time≥1.2s

Repeat positioning accuracy ±0.03mm.

Machine standard of Turntable linkage high-speed manipulator

Two sets of module ≤8.

Custom Standard>8.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Packing | Applying advanced techniques of feeding and handling, flexible conveying, robot integration, visual inspection and laser marking, Yiheda provides a... | |

| Low Voltage Switch Assembly Machine | Introduction of Low Voltage Switch Assembly Machine The low voltage switch assembly machine automated production machinerycompletes multiple funct... | |

| Foam Cutting Machine | A complete solution includes automatic feeding, cutting, high accuracy labeling device and CCD vision detection, etc. High efficiency and high pr... | |

| National Distribution of Industrial Robot System Integrators | HomeNewsIndustry InfoNational Distribution of Industrial Robot System Integrators The industrial robot integration manufacturer is located in the d... | |

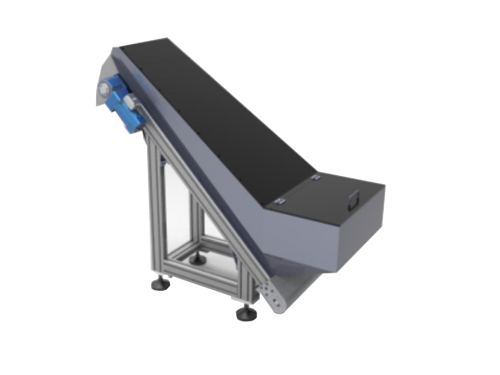

| Feeding conveyor with hopper | With beautiful appearance, compact size and customized service, driven by motor the device can complete material continuous lifting function, norm... |