3D Printing

We are a plastic injection manufacturer. In the spirit of a "one-stop-shop", our own tool workshop as well as an assembly and an international sales service. We have an precision injection moldingprocess with a component load capacity of up to 2 kg in a large machine, carrying out assembly of complex component modules and offer painting and other finishing services all accompanied by the most sophisticated of logistics processes.

In order to meet customers' small batch production, we provide customers with 3D printingrapid processing service.

Compared with other services like the3D printing prototypeand 3D printing plasticsservice, this is the cheapest and fastest way to process the first plate. Before the product design is completed, we suggest customers print samples to test the structural feasibility of the product.

Features of 3D Printing

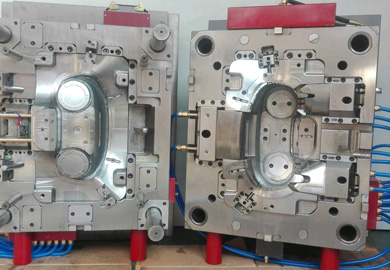

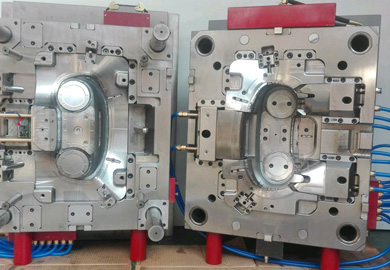

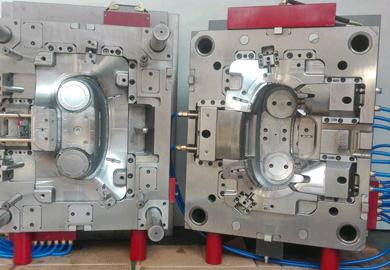

GM-TECH, a reputable injection molding company in china, has designed and manufactured dozens of sets of automobile rear-view mirror molds for Kaiming hall in Murakami, Japan. The products are basically used in Toyota, Honda, and Nissan. In addition, we have also produced dozens of sets of lamp molds for Haila, including headlamp mask, headlight guide strip, headlight reflector, etc.

The Specification of 3D Printing

|

Part name |

sample, prototype |

|

Part material |

SLA |

|

Machining accuracy |

+ / - 0.05 |

|

Exporting country |

New Zealand |

|

Delivery time |

3 weeks |

|

Delivery mode |

DHL 3 days |

|

Mold quality customer satisfaction |

100% |

|

Project cooperation service customer satisfaction |

100% |

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| CNC Components | Gmmoldtech CNC component can greatly reduces the number of tooling, and complex tooling is not needed to process complex parts. If we want to ch... | |

| Multi Cavity Mould | A multi cavity moldis known as a mould with multiple cavities. The multi-cavity mold consists of a multi-cavity of different plastic parts. Thou... | |

| Multi Cavity Mould | High grade steel for core & cavity inserts is used to meet the needs of high-yield, high-precision and precision molds. When customers receive ... | |

| Home Appliance Mould | Household appliances mouldcombines different types of molds such as gold stamping mould, plastic mould, and adsorption mould together. Therefore, h... | |

| CNC Components | CNC Components Gmmoldtech CNC component can greatly reduces the number of tooling, and complex tooling is not needed to process complex parts. ... |