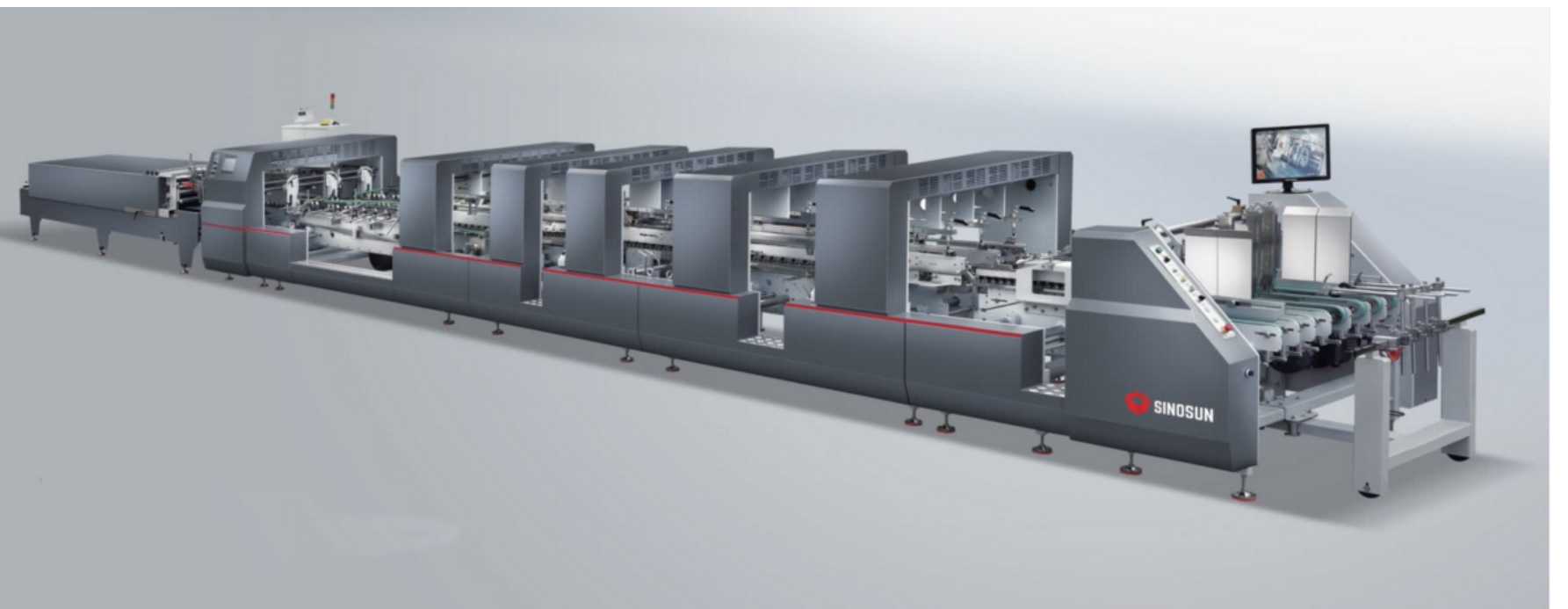

Automatic Punching Machine

Growing, as a reliable packaging machinery company, which is an enterprise of brave to challenge and actively innovate, focuses on the manufacturing and sales of post-press packaging machinery. We are committed to continuously improving production efficiency and packaging technology level by promoting technological progress and service innovation in post-press packaging machinery manufacturing to achieve sustainable and high-quality development of the industry.

Automatic Punching Machine based on international advanced technology, it's widely used in paper cup fan products. It adopts a micro-computer, human-computer control interface, servo positioning, alternating current frequency converter, photoelectric correcting deviation system, centralized oil lubrication.

As one of the automatic punching machine manufacturers, Growingprovide various kinds of products, such as automatic hydraulic punching machine, carton box punching machine, automatic paper hole punching machine, paper bag eyelet punching machineand so on. If you are interested in them, please contact us.

Features of Auto Punching Machine

lAdopt the anilox roller to spread the ink.

lUnwinding tension is controlled by an automatic tension controller from Japan Mitsubishi.

lEach printing unit adopts 360°for registration.

lEach printing unit has one IR dryer.

lThe rubber roller can break away automatically while parking, and run at a low speed to avoid ink being dry.

lThe main motor is adopted the import step-less regulation of frequency conversion.

lWeb guiding, printing, IR drying and punching can be finished in one process.

lIt adopts a micro-computer, human-computer control interface, direct connection servo positioning which make higher accuracy.

Technical Embodiment of Cutting Punching Machine

Lubrication System

Adopting a forced lubrication system to ensure the main driving oil supply regularly and reduce friction and prolong the automatic punching machine pdflife, you could set it to lubricate 10 seconds every 6 minutes.

The die-cutting force is provided by a 5.5KW inverter motor. It is not only power-saving, but also can realize the step-less speed adjustment, especially when coordinate with the extra-large flywheel, which makes the die-cutting force strong and steady, and the electricity can be further reduced.

The coordination between the stepping motor and the photoelectric eye which can identify colours assures the perfect fit of the die-cutting position and figures.

Electrical Cabinet

Frequency converter controls the main motor, with features of low energy and high efficiency.

PLC and HMI

The screen displays the running data and status, all of the parameters can be set through the screen.

Electrical Control System

It adopts microcomputer control, encoder angle detects and control, photoelectric chase and detect, achieving automatic control and detect from paper feeding, conveying, die punching to delivering process. Automatic Tension Control can control the paper tension automatically.

Feeding Unit

Adopting chain type pneumatic roller unwind, tension controls unwind speed, and that’s hydraulic, it could support at 1.5T paper. Max roll paper diameter is 1.5m.

Die Cutting Mould

We adopt the swiss material that could be used for at least 400 million strokes, and if the mould can’t cut well, you could sharpen the blade with a flat grinding machine. And it could be sharpened 4-5 times.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Automatic Front-lay Flute Laminator | STM Series Automatic Front-lay Flute laminator is used to paste the colour-printing surface paper together with the bottom paper (cardboard or corr... | |

| Folder Gluer Machine | As one of folder gluer machine suppliers, we focus on folding and glueing solutions. The Folder Gluer Machine produced by Growing, one of the matur... | |

| Roll Die Punching Machine Inline Flexo Printer | Roll Die Punching Machine Inline Flexo Printer Roll die printing and punching machineinline Flexo Printer based on international advanced technolo... | |

| Automatic Stacker Machine | Auto stacker machineis a flute laminating machine supporting product, which comprises a feeding station, a tumbling table and a receiving station w... | |

| Automatic Stacker Machine | As one of the professional packaging machinery suppliers, Our product line covers a wide range of products including die-cutting machine, film lami... |