Rotary Kiln

CIC’s equipment includes leading standardized heavy equipment and machinery products and related heavy machinery services, which can be sold directly to end customers, business partners, and EPC projects. As a professional heavy equipment companies, CIC serves multiple roles, such as, cement machinery suppliers, mining machinery manufacturers, grinding mill manufacturer, rotary kiln manufacturer, rotary dryer manufacturer, sludge dryer manufacturer and so on.

Since 1950s, CIC had started the manufacturing of pyro processing equipment. These series of pyro processing equipment were used in various field, that enforce us to overcome many difficulties. Nowadays, our products meet the incineration requirements of this equipment for various materials. The complete sets of the pyro processing equipment CIC can provide includes the dry, semi-dry and wet-processed rotary lime kiln, kiln thrust roller, self-return soda steam calciner, rotary kiln in cement industry, environmental dryer and cooler, and etc which are widely used in the industries of cement producing, metallurgy, chemical, environment protecting and so on/,etc.

Design of Rotary Kiln

lShell: Kilned carbon steel and alloy steel shell by automatic welding.

lSupporting Device: Advanced spindle with automatic temperature measuring device and electronic heater unit.

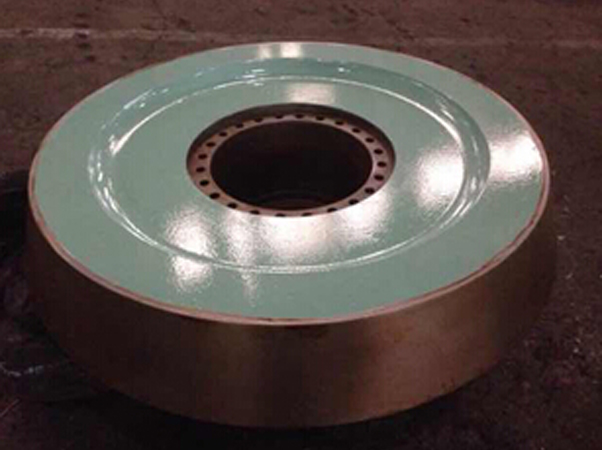

lTyre and Roller: Made of ZG35CrMo steel and 42CrMo steel.

lDriving Device: Equipped with the reducer with the hard tooth surface and flexible diaphragm coupling, by continuous current dynamo or variable-frequency and variable-speed motor.

lKiln Seal Device: Different types of the incineration furnaceare designed to match the needs.

lLow-speed driving device is equipped.

What are the Design Parameters of Rotary Kiln?

lRaw material

lInlet and outlet temperature

lSize of rotary kiln for cement manufacture

lProcessing capacity

lScope of supply

How to Stabilize Kiln Temperature in Summer and Keep the Production?

lThe heat transfer modes of high-temperature gas in a rotating kilnto kiln skin are radiation heat transfer and convection heat transfer;

lThere is only conduction heat transfer among kiln skin, kiln brick and kiln shell;

lThere is only convective heat transfer between the outer wall of the activated carbon kiln/activated carbon rotary kilnand the surrounding environment;

lThe kiln skin is in close contact with the refractory brick, that is, the temperature of the kiln skin at the contact position is the same as that of the brick;

lThe firebrick is in close contact with the kiln body, that is, the temperature of the firebrick at the contact part is the same as that of the kiln body;

lThe inner surface temperature of the kiln is the same as the outer surface temperature (the thickness of the kiln is ignored).

Technical Parameters of Rotary Kiln

Technical Parameters Of Steam Calcination Kiln For Sodium Bicarbonate With Inner Recycling Of Soda

|

Specification |

Capacity |

Design Pressure(Mpa) |

Design Temperature(℃) |

Work Pressure(Mpa) |

Work Temperature(℃) |

||||

|

m |

t/d |

Tube |

Shell |

Tube |

Shell |

Tube |

Shell |

Tube |

Shell |

|

φ2.5×27 |

400 |

Normal Pressure |

270 |

200 |

Normal Pressure |

238 |

200 |

||

|

φ2.8×27 |

520 |

Normal Pressure |

270 |

200 |

Normal Pressure |

238 |

200 |

||

|

φ3×30 |

660 |

Normal Pressure |

270 |

200 |

Normal Pressure |

238 |

200 |

||

|

φ3.2×32 |

800 |

Normal Pressure |

270 |

200 |

Normal Pressure |

238 |

200 |

||

Technical Parameters Of Steam Calcination Kiln For Sodium Bicarbonate With Inner Recycling Of Soda

|

Specification |

Heat Exchange Area |

Installation Inclination |

Main Motor Power |

Speed Rate |

Main Drive |

Slow Speed Drive |

Net Wt. |

Max Wt。 With Filler |

Product Features |

|

m |

M2 |

% |

kw |

r/min |

r/min |

r/min |

kg |

kg |

|

|

φ2.5×27 |

≥2500 |

2 |

160 |

980 |

7 |

198000 |

250000 |

Light Soda Ash |

|

|

φ2.8×27 |

≥3100 |

2 |

160 |

1480 |

228000 |

270000 |

Light Soda Ash |

||

|

φ3×30 |

≥3600 |

2 |

220 |

1480 |

300800 |

350000 |

Light Soda Ash |

||

|

φ3.2×32 |

≥4000 |

2 |

310 |

1480 |

350000 |

395000 |

Light Soda Ash |

Technical Parameters Of Steam Calcination Kiln For Sodium Bicarbonate With Inner Recycling Of Soda

|

Specification (m) |

Basic Parameters (Speed Rater/min) |

Inclination (%) |

Capacity (T/d) |

Main Motor Power(kw) |

Thrust Type |

Support Type |

Weight (t) |

Remarks |

|

|

1 |

Φ3.2×50 |

1000 |

160 |

Hydraulic Type |

Sliding Type |

||||

|

2 |

Φ3.5×52.5 |

1500 |

180 |

||||||

|

3 |

Φ4×56 |

2000 |

250 |

489 |

|||||

|

4 |

Φ4×60 |

2500 |

315 |

523 |

|||||

|

5 |

Φ4.3×64 |

3200 |

420 |

Excluding seals of kiln head and kiln rear |

|||||

|

6 |

Φ4.8×72 |

5000 |

630 |

Excluding kiln head cover |

|||||

|

7 |

Φ4.8×74 |

4 |

5000 |

630 |

864 |

||||

|

8 |

Φ5.2×61 |

5500 |

800 |

859 |

|||||

|

9 |

Φ5×80 |

max 3.5 |

4 |

6000 |

800 |

||||

|

10 |

Φ5.6×87 |

max 4.23 |

4 |

8000 |

800 |

1201 |

Cooperating with Burleigh Hughes |

||

|

11 |

Φ6×90 |

max 3.5 |

4 |

10000 |

845×2 |

||||

|

12 |

Φ6×95 |

max 5 |

4 |

10000 |

950×2 |

Cooperating with Smith |

CIC Reference List for Rotary Kiln

|

Client |

Size |

Qty |

Capacity of Cement Plant |

|

|

1 |

Conch Cement Group (Tong Ling) |

Ф6.3×98m |

1 |

12000t/d |

|

2 |

Conch Cement Group (Tong Ling) |

Ф6×95m |

2 |

10000t/d |

|

3 |

Conch Cement Group (Zong Yang) |

Ф6×95m |

1 |

10000t/d |

|

4 |

Conch Cement Group (Xu Zhou) |

Ф6×90m |

1 |

10000t/d |

|

5 |

Tian Rui Cement Group (Yingyang) |

Ф6.2×92m |

2 |

10000t/d |

|

6 |

Shanshui Group |

Ф6.2×92m |

1 |

10000t/d |

|

7 |

Sinoma International(Saudi Arabia) |

Ф6.2×92m |

3 |

10000t/d Parts |

|

8 |

Sinoma International(UAE) |

Ф6.2×98m |

1 |

10000t/d Parts |

|

9 |

Zhonglian Cement Group |

Ф6.2×90m |

1 |

10000t/d |

|

10 |

Conch Cement Group (Chi Zhou) |

Ф5.6×87m |

1 |

8000t/d |

|

11 |

ASTurkey |

Ф5.6×87m |

1 |

8000t/d |

|

12 |

Anhui Wanwei Co Ltd |

Ф5.0×80m |

1 |

6000t/d |

|

13 |

Nanyang Hangtian Cement Co Ltd |

Ф5.2×78m |

1 |

6000t/d |

|

14 |

Nanjing Kaisheng Engineering Comany(Turkey) |

Ф5.2×74m |

1 |

6000t/d |

|

15 |

Nanjing Kansheng Engineering Comany(Vietnam) |

Ф5.2×82m |

1 |

6000t/d |

|

16 |

Jiangsu Helin Cement Co Ltd |

Ф5×74m |

1 |

6000t/d |

|

17 |

Hongshi Cement Group |

Ф5×74m |

2 |

5000t/d |

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Thrust Roller | CIC is a more than 30-year manufacturer and reputed supplier of thrust rollerused in rotary kilns, rotary type driers and so on. CIC has been speci... | |

| Dry Ball Mill | Dry ball millis suitable for all kinds of metal and nonmetal ores, including materials that will react with water, such as cement, marble, and othe... | |

| SAG Mill | SAG Mill Semi autogenous mills or SAG mills as they are often called, can perform grinding operations equivalent to two or three stages of crushin... | |

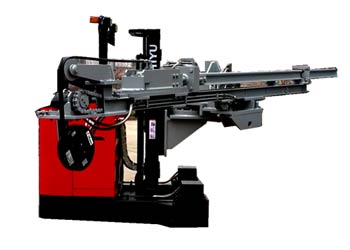

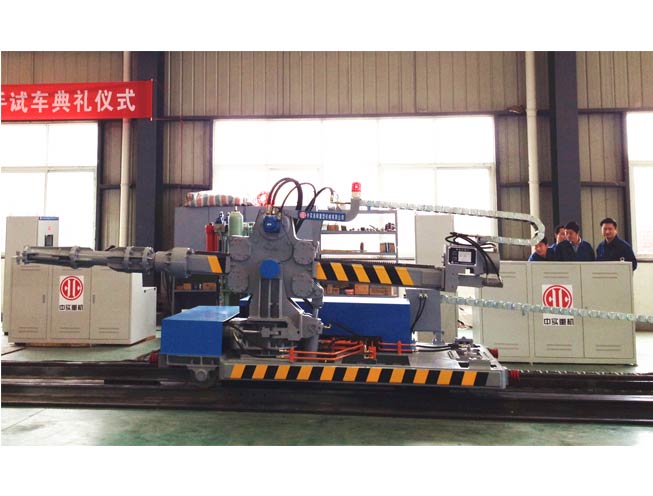

| Furnace Robotic Arm Machine | With the development of modern science and technology, industrial arm is a kind of high-tech automatic intelligent mechanical production equipment ... | |

| Furnace Tapping Machine | We developed the discharge furnace robotic arm, based on the working process and tools of manual operation of slag port opening and closing of the ... |

Похожие товары

| Micronized polypropylene wax for injection moulding | Продавец: Syntop chemical Co.,Ltd. | The incorporation of polypropylene micronized wax into injection moulding processes delivers the ... | |

| Drum Type Mobile Mixing Station | Продавец: Yousheng Machinery Equipment Co.,Ltd | Drum Type Mobile Mixing Station Drum Type Mobile Mixing StationPortable Drum Concrete Batch Plan... | |

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | Продавец: XIUCHENG RFID | Size:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transf... | |

| Micronized wax used for industrial paint processing | Продавец: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... |