Aluminum Extrusions

OTALUM was founded in 1984 and after 36 years' development, we have now already become a professional aluminium profile manufacturerfor architectural systems and industrial applications. Our factory is well equipped with 40 extrusion lines with a capacity of 500- 5500 tons. Our total annual output can reach 15000 tons, and we produce a wide range of products, including window and door systems, curtain wall, performance louvre, heat sinks, solar panel framings. Customized service is available. Our engineers can help you design your extrusion structure and produce your own system.

Otalum isaleading aluminum sign extrusions manufacturerin Southeast-China, Australia, South America and Southeast-Asia, offering a wide range of production capacities in creative aluminium extrusions, finishing and fabrication. Aluminium is a material combining the characteristics of light, strong, anti-rust, recyclable and economical, which provides the designers and manufacturers with precious choices to maintain a balance between function and cost.

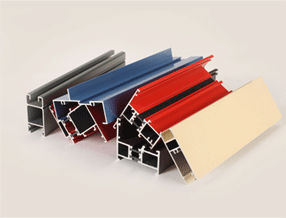

Otalum's sign extrusion profilesare mainly used for a wide variety of markets and applications, such as building and construction, machinery, automotive, furniture, LED, heat sink. These l aluminum profilesections not only offer good functions but also perform well during actual use. All our extruded profiles can be produced with the processes of mill finish, anodizing, powder-coating, PVDF painting and wood finishing. Thermal break profiles are also available at Otalum and we also offer a full range of fabrication processes.

Types of Aluminium Extrusion

Various types of aluminum extrusion profiles can be created with different thicknesses. These extruded profiles can have a variety of complex void spaces, which are necessary for end-use applications. In order to facilitate various automation applications and meet any performance and weight requirements, a variety of internal voids can be used. The most common type of aluminum profile is hollow beam profile, which is just a variation of square profile. There are other contour types, such as triangular, single radius and L-shaped contours.

Aluminium Construction Profiles

Building & Construction is always the main market in the fletcher aluminium extrusionssections industry. In this area, Otalum offers a one-stop solution, including profiles design, die development, extrusion, finishing, fabrication and installation. We have an experienced team to arrange the whole process, ensuring the final outcome can totally meet your requirement. We also carry a wide range of dies for construction aluminium extruded products. All requests are made to order. Please, specify alloy, temper, length, quantity, surface finish, end-use and any special instructions regarding tolerance, delivery, packing and certification when ordering.

Industrial Aluminum Profile

Industrial markets are another big part of our business. We supply many big-scale manufacturing companies in the areas of machinery, equipment, electrical and automotive with first-class extrusion capacity, all kinds of surface finishing and fabrication services.

Standard Aluminium Extrusion Shapes

Standard aluminium profiles are the most basic products in the business. We offer a wide range of choices of angles, tubes, bars and U-channels with the standards of different countries, covering almost all the common use.

Aluminium Extrusion Uses

Aluminium extrusion transforms aluminum alloy into a variety of products suitable for consumers and industrial markets. Aluminum profiles have many uses in electronics, automobiles, public transportation, bridge deck paving, telecommunications, solar energy, renewable energy and other industries.

The aluminum panel extrusionsmake full use of the excellent ductility of aluminum. The aluminum alloy billet is heated to soften it, and then pressed into a special steel mold with a hydraulic press or a punch under high pressure to form a shape. The result is an aluminum sheet that maintains the specific shape of the mold.

Aluminum Extrusion Alloys

Different alloys in different states can make bulk extruded aluminumprofiles to meet the various needs-from household items to space vehicles. Basically, aluminum profiles can be extruded from any deformable aluminum alloy (even casting) in one way or another. However, metals need special flow characteristics to flow through the holes and cavities of the matrix under high temperature compression. Therefore, metals should: fill all the holes at the exit of the matrix at the same high speed, provide the required micro-structure, reach the predetermined strength and other characteristics and shape the best surface quality.

Therefore, special aluminum alloys specifically for pressing (extrusion) are being developed. In this way, the chemical composition of these alloys is optimized to make them most suitable for the conditions of the pressing process and to ensure the required quality of the molded products.

Custom Aluminium Extrusions

Extrusion is defined as the process of shaping material, such as aluminium, by forcing it to flow through a shaped opening in a die. Customized aluminum mirror frame extrusionshave the benefit of producing complex and integral shapes with close tolerance. As a mature aluminium extrusions company in China, Otalum can assist you in designing your own extrusions, thereby achieving specific functions.

FAQs of Aluminum Extrusions

Q

What is aluminum extrusion?

Aluminium extrusion is a process where aluminium alloy is transformed into items with a specific cross-sectional outline for subsequent wide-ranging uses. A simpler definition would refer to aluminium being squeezed all the way through an orifice.

Q

How does aluminum extrusion work?

Aluminum extrusion is defined as a process by which aluminum is forced to flow through a shaped opening in a die. A powerful press pushes the aluminum through the die and it emerges from the die opening. The outcome is a long profile with the same shape as the opening in the die.

Q

How strong is Aluminium extrusion?

Aluminum extrusions can be made as strong as what we need and, due to the nature of the extrusion process, the strength can be focused on where it is really needed by increasing wall thicknesses and adding internal reinforcement in the profile design. Cold-weather applications are well, as profile aluminium extrusion becomes stronger as temperatures fall.

Q

What is the difference between cast aluminum and extruded aluminum?

Extrusion is defined as the process of shaping material, such as aluminium, by forcing it to flow through a shaped opening in a die. Cast aluminium is the resulting product created after molten aluminum is poured into a mold.

Q

What is considered extruded aluminum?

Extrusion is defined as the process of shaping material, such as aluminum, by forcing it to flow through a shaped opening in a die. Extruded aluminium emerges as an elongated piece with the same profile as the die opening.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Aluminium Square Tube | Extruded aluminum square tubeis frequently used in the places where lightweight and corrosion resistance is important, such as framework, support c... | |

| Aluminium Equal Angle | The aluminium equal angle is an important type of aluminium L angle with legs of equal lengths and equal thickness. In Otalum, we offer a wide ran... | |

| Aluminium Unequal Angles | Aluminium unequal angleare "L-shape" extruded profiles with legs of unequal lengths and equal thickness. In Otalum, we offer a wide range of une... | |

| Industrial Aluminum Profile | Otalum’s served markets also include a variety of industrial and consumer-based markets known as "Industrial Markets". These are comprised ... | |

| Aluminum Angles | As an aluminium section factory, Otalum supplies a comprehensive range of over 1000 different standard aluminium profiles in a wide spectrum of spe... |

Похожие товары

| YC160W Wheel excavator YC160W | Продавец: Guangxi Yuchai Equipment Technology Co., Ltd | YC160W Wheel excavator YC160W wheel excavator is a new generation of full hydraulic wheel excavat... | |

| Yuchai U20 mini excavator | Продавец: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai U20 mini excavator Improvements in Over 80 Details: Tailless Excavator U20 is a Yuchai ... | |

| Yuchai YC80 small excavator | Продавец: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai YC80 small excavator International brand engine It is equipped with Yanmar 4TNV98C natur... | |

| Top Type Hydraulic Breaker | Продавец: Guangxi Yuchai Equipment Technology Co., Ltd | Top Type Hydraulic Breaker With the higher restriction of blasting control,hydraulic breakeris w... | |

| S35-Electric Skid Steer Loader | Продавец: Guangxi Yuchai Equipment Technology Co., Ltd | S35-Electric Skid Steer Loader Yuchai S35 Electric Skid Steer Loaderis compact and flexible, des... |