Bio-polishing Enzyme QM-111

BioPolish EnzymeQM-111

[Main composition]

Cellulosic enzyme compound

[General properties]

Appearance: Brown liquid

pH: 4.5-5.0

[Product features]

Effectively remove exposed the pale and yarn end, improve the fabric hand feels and shine.

Bio-polishing enzyme can reduce pilling and improve hydrophilicity.

Suitable for removing surface fluff of cellulose fibre.

It can improve the smooth surface of the fabric and give a good hand feeling after processing.

[Application]

Suitable to cotton , mucilage, flax and ramie fabric.

PH: 4.0-5.5

Bio-polishing Enzymes: 0.5-2% (o w f)

15-40 minutes

Temperature: 50-55℃

Bath radio: 1:5-15

- :

1) Please add water at 1:5-15 bath radio, washing agent 0.25-0.5% and heat to 85℃at 10 minutes. final with drain and washing

2) Adjust PH to 10-10.5 for 10 minutes, and then drain.

[Packaging and

25 kg/polyethylene drum, keep it cool and dry, 6 months in sealed container under 25℃ can keep the activity.。

[Notes]

The data contained in this literature are based on our current knowledge and experience. It is imperative that it be tested to determine, to your satisfaction, whether it is suitable for your intended use and application. We shall not take any responsibility in any situation for improper use.

[Sample supply]

If you need samples for testing, please feel free to contact us, we will recommend suitable products according to your requirement.

[Shipment]

We can support LCL shipment and FCL shipment, for LCL shipment, we will pack the goods with wool pallet to save the products during transportation.

[Quotation]

According to your order quantity, we can supply FOB, CIF, EXW price.

[Order MOQ]

Normally, HT Fine order MOQ is 3 tons per model and we can offer lowest price with more quantity.

If you want to know more types of textile auxilaries, please visit our website.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Auxiliaries for Cotton | Cotton dyeing is operated in a certain temperature, time, PH value and the required dyeing agent for cotton. The common agents for cotton dyeing an... | |

| Antisatic Agent KD | This product is suitable for polyester, polyamide, such as polyvinyl chloride staple fibre spun synthetic fiber spinning static elimination, with e... | |

| Water-saving Soaping Agent 2137B | A neutralization soaping agent for reactive dyesof various fabrics with reactive dyestuffs that confers excellent soaping fastness. Low foam, easy ... | |

| Cationic Fixing Agent | Cationic dye fixing agentmainly through the cation and dye molecules in the anion group formation of ionic bonding, thereby sealing the water-solub... | |

| Scouring Agent in Textile | Definition of scouring agent in textile Scouring in textilerefers to a large number of auxiliaries with functions of emulsifying, penetrating, w... |

Похожие товары

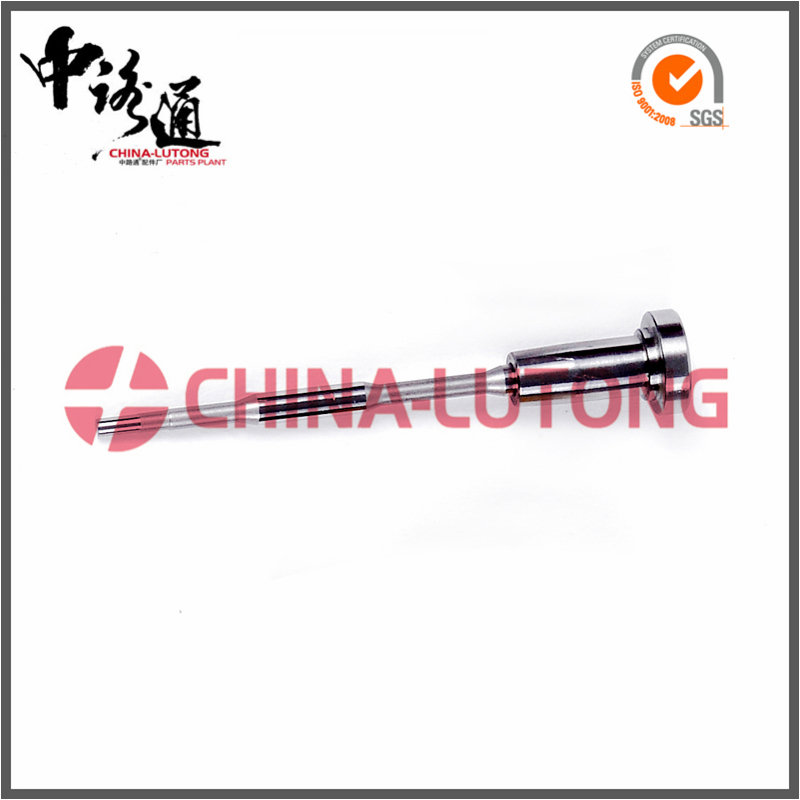

| Common Rail injector control valve F00V C01 365 & Common Rail injector control valve F00V C01 368 | Продавец: zhonglutong | Common Rail injector control valve F00V C01 365 Common Rail injector control valve F00V C01 368 C... | |

| Common Rail injector control valve F00V C01 362 & Common Rail injector control valve F00V C01 363 | Продавец: zhonglutong | Common Rail injector control valve F00V C01 362 Common Rail injector control valve F00V C01 363 C... | |

| Common Rail injector control valve F00V C01 358 & Common Rail injector control valve F00V C01 359 | Продавец: zhonglutong | Common Rail injector control valve F00V C01 358 Common Rail injector control valve F00V C01 359 C... | |

| Common Rail injector control valve F00V C01 355 & Common Rail injector control valve F00V C01 356 | Продавец: zhonglutong | Common Rail injector control valve F00V C01 355 Common Rail injector control valve F00V C01 356 C... | |

| Common Rail injector control valve F00V C01 352 & Common Rail injector control valve F00V C01 353 | Продавец: zhonglutong | Common Rail injector control valve F00V C01 352 Common Rail injector control valve F00V C01 353 C... |