Aluminum Stamping

Aluminum alloy stamping refers to stamping hardware made of aluminum alloy.

Orienson's Aluminum Stamping

Aluminum alloy is the most widely used non-ferrous metal material in the industry. It has the advantages of low density, high strength, good plasticity, etc., and also has strong electrical conductivity, thermal conductivity, corrosion resistance, and solderability. The metal stamping parts made of it are indispensable and important parts in aviation, aerospace, automobile, machinery manufacturing, shipbuilding, and chemical industries.

Types Of Surface Treatments For Aluminum Stamping Parts

Anodic oxidation can effectively make up for the lack of surface hardness and wear resistance of aluminum stamping parts, thus the stamping parts can have a more beautiful appearance and obtain a variety of colors through anodic oxidation.

Common drawing methods include thread, disorderly lines, spiral lines, straight lines, etc. After the drawing process, the surface of aluminum metal stampingparts has clear micro marks, showing a good visual effect on the appearance.

Types Of Surface Treatments For Aluminum Stamping Parts

Sandblasting for aluminium stampingparts has the effect of removing surface burr and oil, which can improve the surface finish by controlling the surface roughness of the material, as well as improve the adhesion of the surface coating of the stamping parts to make it more beautiful and durable.

Polished aluminum stamping chinaparts can be close to the mirror effect, improve the grade and beauty of the product, but will reduce the durability of the parts.

Benefits of Aluminum Stamping

The density of aluminum is 2.7, about 1/3 of that of copper (8.9) or steel (7.8). For space aircraft, ships, vehicles, and other vehicles and buildings, lightweight is very beneficial, but also can save moving costs and processing costs, reduce costs, It is widely used in the construction industry, civil industry, and other fields.

Good Corrosion Resistance of Aluminum Stamping

Good Corrosion Resistance, Weather Resistance

Aluminum and aluminum alloy in the atmosphere can form a hard and dense layer with the good corrosion resistance of oxidation film, by means of anodic oxidation, electrophoretic coating, powder spraying, and other surface treatment, we can further improve the corrosion resistance of aluminum.

Good Decorativeness of Aluminum Stamping

Good Decorativeness

Because of its good plasticity, aluminum alloy can be processed into various sizes of products, it is ornamental and decorative on appearance with different colors of the film layer.

Good Thermal Conductivity of Aluminum Stamping

Good Thermal Conductivity

The thermal conductivity of aluminum is very high, 3 times that of iron, only second to silver, gold, and copper in metal. Therefore, aluminum alloy is a good material for making radiators and heaters.

Application Of Aluminum Stamping

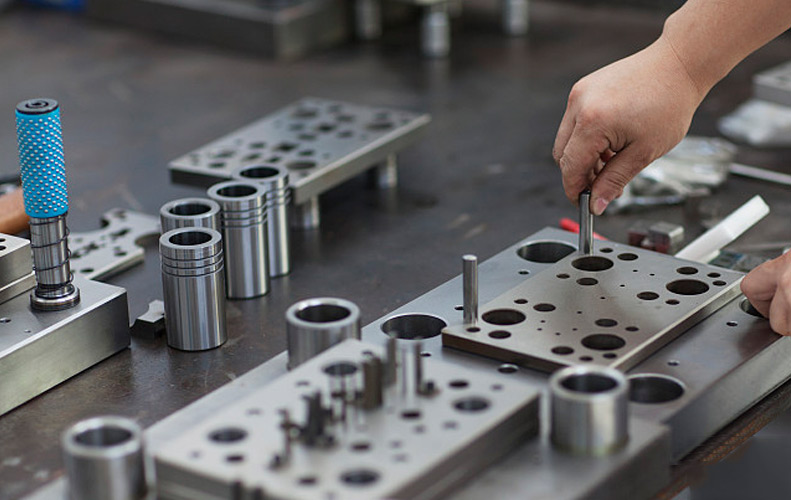

Aluminum Stamping Design

High repair rate, high scrap rate is still the main difficult problems In the production process of aluminum stamping parts in the industry. At present, the main pain points in production focus on necking cracking and material chips. Combined with nearly twenty years of production and maintenance experience of hundreds of types of aluminum stamping parts.

We have had many experiences and measures to solve the common problems of neck cracking and material chips in the production of aluminum stamping parts from the molds, stamping equipment, raw materials, technology, production testing.

As a professional metal stamping supplier, we provide metal stamping, metalwork and stamping, stamped aluminum panels, stamping aluminum, cnc machiningand etc. Want to know more, contact us.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Stainless Steel Stamping | Stainless steel stampingis the process of stainless steel material processed by using the mold, which makes its deformation or fracture has a certa... | |

| Fine Blanking Parts | Fine blanking is short for precision blanking. Orienson's Fine Blanking Parts Fine blanking is a kind of precision stamping processing technology... | |

| Automotive Metal Stamping | Orienson has expanded into the automotive components market for years and produces the highest quality components for the world's top automotive br... | |

| Optical Fiber Communication Metal Stamping | Orienson is dedicated to helping our customers leverage the power and speed of optical fiber communications. Our high-quality products meet the inc... | |

| Copper Stamping | Copper stampingis the processing of copper metal materials into custom-shaped hardware through stamping die. Orienson's Copper Stamping Copper is ... |

Похожие товары

| Wedge Wire Screw Press Screen for Manure Separator | Продавец: Apoaqua | Wedge wire screw press filter screen is mainly used in the application of dewatering manure in fa... | |

| gardening cultivating tools | Продавец: Dongyang Guorui Industry And Trade Co., Ltd. | Our gardening cultivating tools are the epitome of quality and functionality, desig... | |

| Kingwood Wood Pellet | Продавец: Jiangsu Kingwood Industrial Co., Ltd. | Our Wood Pellets are produced through a meticulous process that involves compressin... | |

| 2BV2 070 Water Ring Vacuum Pump for Mine | Продавец: Greentech International (Zhangqiu) Co., Ltd | 2BV2 070 Water Ring Vacuum Pump for Mine2BV series liquidring vacuum pumps are suitable for pumpi... | |

| 2sk-30 Liquid Ring Vacuum Pump/Motor Not Included | Продавец: Greentech International (Zhangqiu) Co., Ltd | Greentech International (Zhangqiu) Co., Ltd is the professional liquid ring vacuum pump supplier.... |