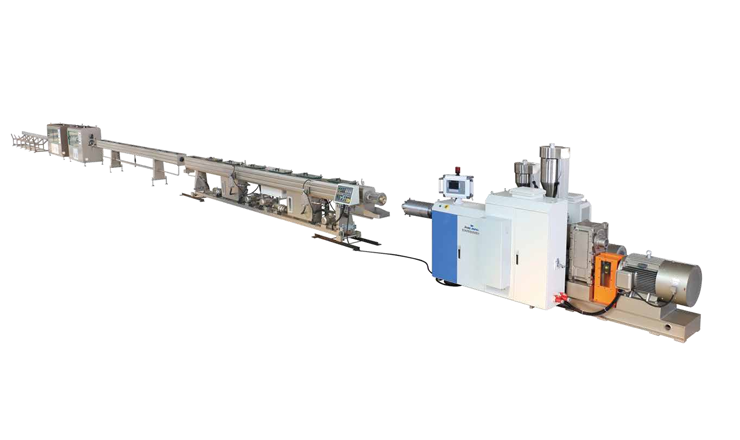

ASA Film Extrusion Line

Because of its outstanding anti-aging properties, ASA films are widely used in the field of roofing tiles. JWELL ASA thin film production line can achieve online thermal recombination at the same time, with uniform thickness, no color difference, and high bond strength.

ASA ExtrusionLine overcomes the problem of chromatic aberration existing in traditional co-extrusion ASA composite and saves raw material cost.

Description About ASA Film Extrusion Line

|

Place of origin |

China |

|

Brand name |

Jwell |

|

Model number |

JWS90 |

|

Certification |

CE ISO |

|

Minimum order quantity |

1 set |

|

Packaging details |

Wooden pallet packing |

|

Delivery time |

90days |

Specifications of ASA Film Extrusion Line

|

Species |

ASA Film Extrusion Line |

|

Model |

JWS90-1500 |

|

Material |

ASA material |

|

Production thickness(mm) |

|

|

Products Width(mm) |

1400mm |

|

Output (kg/h) |

150-180kg/h |

ASA Film Extrusion Line Applicaion

ASA Film Extrusion Line Applicaion

ASA film is a film made of polyvinyl chloride, polyethylene, polypropylene, polystyrene, and other resins for packaging and film coating. Plastic packaging and plastic packaging products account for an increasing share in the market, especially composite plastic flexible packaging and surface coating of building materials have been widely used. ASA film extruderhas the advantages of high weather resistance, impact resistance, aging resistance, UV resistance, corrosion resistance, anti-static, self-cleaning, green environmental protection, and so on; ASA functional film can effectively solve the problems of uneven thickness, white exposure, color difference, scratch and so on; It can greatly improve the product quality and stability, so as to reduce the waste of raw materials and reduce the cost.

ASA Film Extrusion Line Performance and Advantages

The production process of ASA resin film is mainly extrusion traction and stretch molding. The equipment is composed of screw extruder (single and double), die, three roller calender, cooling unit, and winding device. ASA resin particles undergo drying, heating, melting, mold forming, tablet pressing, cooling, film winding, and other processes to produce film products with a thickness of 5-15 wires (80-150um). Because of its outstanding anti-aging properties, ASA films provide by jwell extrusion are widely used in the field of roofing tiles.

JWELL ASA thin film production line can achieve online thermal recombination at the same time, with uniform thickness, no color difference, and high bond strength. It overcomes the problem of chromatic aberration existing in traditional co-extrusion ASA composite and saves raw material cost.

Jwell extrusion machineryis a high-tech manufacturer specializing in the research and development of yarn spinning machines, pet sheet extrusion line.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| PP Pipe Extrusion Machine | The series of PP pipe extrusion machine lines mainly extruded production: MPP power pipe, PPR, Pert, PEX, cold & hot water pipe, RB, PO, MULTI-... | |

| POY Spinning Machine | POY spinning machine adopted Newly designed Spin-Beam with less energy consumption by 30% compared with conventional ones. Adopted Bottom mounte... | |

| HDPE Pipe Extrusion Machine | HDPE extrusion machineproduction line adopts the most advanced technology of Europe, It is a new research achievement of energy-saving production l... | |

| Plastic Compounding Machine | The twin-screw extruder is composed of a transmission device, a feeding device, a barrel, and a screw, and the functions of each component are simi... | |

| Automatic Blow Molding Machine | blow molding machinehas great advantages in the clean production and energy saving of blow molded products, and automatic blow molding machine's ... |