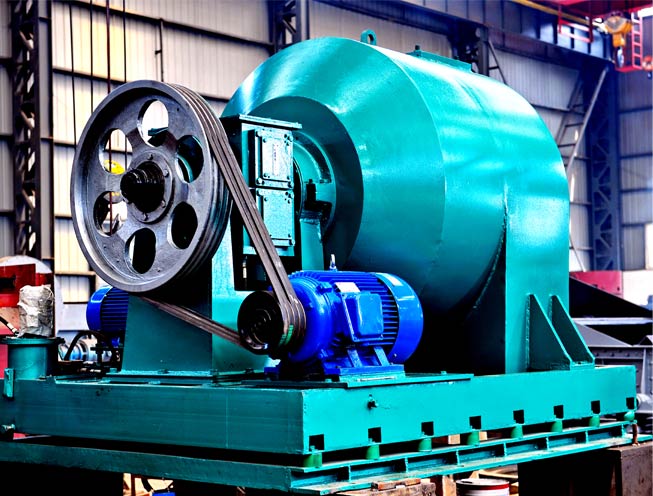

Horizontal Centrifuge

TWZ series horizontal vibratory centrifuge belongs to the centrifugal dewatering machine, the series of horizontal vibratory centrifuge is mainly used for dehydration of fine and medium coal (0.5 to 26mm), it can also be used for other similar materials dehydration.

Structural Features of Horizontal Centrifuge Machine

The horizontal vibratory centrifuge made the material separated by solid liquid on a high-speed rotating screen, a vibrating power is attached to the material on the screen by the excitation system to realize the solid-liquid separation with automatic unloading. The TWZ series has many advantages, including high production, small crushing degree, long life period of screen, stable, convenient to fix, simple structure, low noise, high reliability and low cost.

Main Features of Horizontal CentrifugeMachine

High treatment ability, good dehydration effect.

Small crushing degree, the screen basket is more wearable, long life period.

TWZ series have inertial resonance vibration system, amplitude and product rate are stable and reliable. The TWZ vibration system has the advantages of smooth running, low noise, simple structure, convenient maintenance and energy saving.

Horizontal centrifuge machine can be applied as coal centrifuge and sludge dewatering centrifuge.

Working Principle of Horizontal Centrifuge Machine

Materials entered into the bottom of the screen basket through a feed-in tube with an enamel and screen base, materials within the screen barrier subjected to centrifugal force and closed to the screen surface. Under the effect of vibration, the material layer moved toward large end of screen basket evenly, the dehydrated material was thrown around the screen basket, falling into a discharge port at the bottom of the shell and discharged. The moisture in the material through the material layer and the sieve seam was thrown around the shell under the action of centrifugal force, then along the shell wall to the drain outlet.

Working Principle of Horizontal Centrifuge

Technical Performance of Horizontal Centrifuge Machine

|

Basic Parameters |

Unit |

Model |

||||||

|

TWZ850 |

TWZ10A |

TWZ1150 |

TWZ1300 |

TWZ1400 |

TWZ1500 |

|||

|

Feed Size |

mm |

≤50 |

0-25 |

0-50 |

≤50 |

|||

|

Processing Capacity |

t/h |

30-50 |

50-100 |

100-150 |

180-250 |

200-300 |

250-350 |

|

|

Product Moisture |

% |

44325 |

||||||

|

Large Diameter of Screen |

mm |

850 |

1000 |

1150 |

1300 |

1400 |

1500 |

|

|

Size of Screen Cut |

mm |

|

||||||

|

Vibration Frequency |

Hz |

25 |

255 |

25 |

25 |

25 |

25 |

|

|

Double-Amplitude |

mm |

44292 |

44292 |

44292 |

44292 |

44292 |

44292 |

|

|

Power of Main Motor |

Kw |

15 |

22 |

45 |

55 |

75 |

||

|

Power of Vibration Motor |

Kw |

4 |

11 |

15 |

||||

|

Power of Oil Pump Motor |

Kw |

|||||||

|

Size |

Length |

mm |

2060 |

2150 |

2800 |

2700 |

3100 |

3170 |

|

Width |

mm |

1510 |

1875 |

1930 |

2260 |

3090 |

2975 |

|

|

High |

mm |

1625 |

1765 |

1930 |

2245 |

2295 |

2400 |

|

|

Weight |

kg |

2500 |

2620 |

5527 |

6500 |

9200 |

10000 |

|

As one of the most professional heavy equipment suppliers, CIC provides auto drilling and tapping machine, tapping drilling machine, sludge dryerand etc. Want to know more, contact us now.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Horizontal Centrifuge Machine | TWZ series horizontal vibratory centrifuge belongs to the centrifugal dewatering machine, the series of horizontal vibratory centrifuge is mainly u... | |

| Vertical Centrifuge | The vertical centrifuge machine is made up of the screen which diameter range from 700 to 1,000 mm , the rotor body (including the blade), transmis... | |

| Metallurgical Furnace | CIC main advantage in nonferrous metallurgical furnacelies in the manufacture of horizontal rotary furnace, Rotary refining furnace and bottom blow... | |

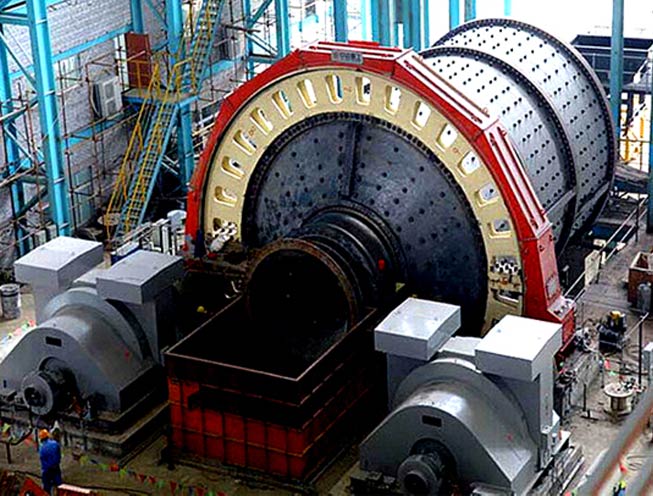

| Wet Grid Ball Mill | Wet Grid Ball Mill Wet ball millis a kind of energy-saving industrial grinding mill which adopts rolling bearings and has high efficiency. Wet g... | |

| Industrial Grinding Mill Machine | Independent design and manufacture can be achieved according to customer demand and different working conditions. CIC grinding machine suppliers us... |

Похожие товары

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | Продавец: XIUCHENG RFID | Size:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transf... | |

| Micronized wax used for industrial paint processing | Продавец: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... | |

| Fungicide Supplier | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Fungicide Supplier | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... |