DDMC Single Pulse Jet Bag Filter Dust Collector

Single-pulse jet bag filter is widely used in mining, electric furnace smelting, machinery manufacturing, chemical products, cement, building materials, grain processing and other industrial and mining enterprises warehouse top, bottom, belt transmission and local dust source dust. The jet pulse dust collector has the advantages of small size, large air volume, compact structure and easy use. The structure of jet pulse filter is mainly composed of a fan, a box, an ash discharging device, a control system and the like. All of them are placed in a box made of welded steel plates, baked and rust-proof, beautiful in appearance, scientific in structure, and easy to operate. The lower flange of the unit is directly coupled to dust collector equipment such as the top of the warehouse, silo, and belt transportation to remove dust in situ, and the dust is directly recovered.

Single pulse jet bag filter working principleDust-laden gas enters the box through the air inlet, and the purified gas filtered by the pps filter bag is directly discharged by the fan. With the increase of filtration time, more and more dust accumulates on the filter bag of the pulse bag dust collector, which increases the resistance of the filter bag, resulting in a gradual decrease in the processing air volume. For normal operation, the filter bag of jet pulse dust collector must be cleaned in order to control the resistance within a certain range. When the ash is cleaned, each control valve is triggered by the pulse control device to open the pulse valve. The compressed air in the airbag is injected into the filter bag through the pulse valve to the holes of the injection pipe. The filter bag of pulse bag dust collector instantaneously expands rapidly and the product is attached to the filter. The dust on the surface of the bag falls off and the filter bag is regenerated. Cleared dust falls and ash buckets are discharged through the drain valve. In this way, the dust accumulated on the filter bag of the pulse jet bag filter is periodically pulsed and cleaned so that the purified gas passes normally.

Jet Pulse Dust Collector Advantages

The versatility of pulse jet bag filters makes them very useful in a wide range of industries, and pulse jet bag filter systemoffers several advantages over other types of dust removal systems.

The jet pulse dust collector is incredibly versatile over a range of temperatures, pressures and airflow chemistries.

The jet pulse dust collector is very compact and can fit any size and shape.

The pulse bag dust collector is best suited for external and internal use as well as hot and cold process temperatures.

Well designed by Senotay, a mature pulse bag type dust collectorfactory, the pulse jet type bag filter is budget friendly and easy to operate.

These jet pulse filters can remove particles up to 2.5 microns and have a high efficiency.

The pulse bag dust collector is energy efficient and requires less maintenance.

The high collection efficiency of the jet pulse filter helps to strengthen the position of most pulse jet bag filter units, as it is the most used industrial dust collector.

Jet Pulse Filter Maintenance

To ensure smooth and efficient pulse jet bag filter operation, it is necessary to schedule regular jet pulse

filter maintenance and service.

The following are some maintenance tips to ensure filter performance.

Check and obtain a constant reading on the differential pressure gauge, which allows you to solve problems early if the equipment fails.

Clean the jet pulse filter's lines and sensors regularly to avoid equipment damage and malfunction.

Perform regular leak tests to detect potential filter failures in advance. Use leak detection powders and monochrome lights to determine the exact leak point of the jet pulse dust collector.

Inspect and service exhaust fans regularly for any signs of malfunction, such as vibrations, periodic squeaks, and changes in operating criteria.

Inspect and clean the piping of pulse jet type bag filter regularly to avoid clogging the system.

Make sure the diaphragm valve is not leaking.

Replace any worn diaphragms to prevent waste of compressed air.

Periodically check the filter media to ensure proper operation. Schedule periodic testing for leaks and dust cake quality.

Ensure that filters are changed frequently according to the manufacturer's instructions. Always use the original manufacturer's jet pulse filters to ensure consistent material quality and efficiency.

Bag Filter Pulse Jet Cleaning

Bag filter pulse jet cleaning is achieved by pulse jetting fibers. In removing impurities, the jet pulse filter fibers remove dust from the process gas by impact, direct interception, diffusion and electrostatic forces.

Senotay, a professional dust collection system manufacturer, is always at your service.

Now the price of china dust collector equipmentis affordable, if you have needs, please contact us.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| DMF-Z Right Angle Electromagnetic Pulse Valve | DMF-Z Right Angle Electromagnetic Pulse Valve Product introduction: The valve is imported from abroad (also known as the diaphragm valve) is the co... | |

| Needle Felt Filter Bags | Anti-Static Polyester Needle Felt Bag Anti-static dust bag is currently ideal dust filter material, with good ventilation energy, high dust removal... | |

| Bucket Elevator | The havethe advantages of large conveying volume, high lifting height, stable and reliable operation, and long life. Its main performance and param... | |

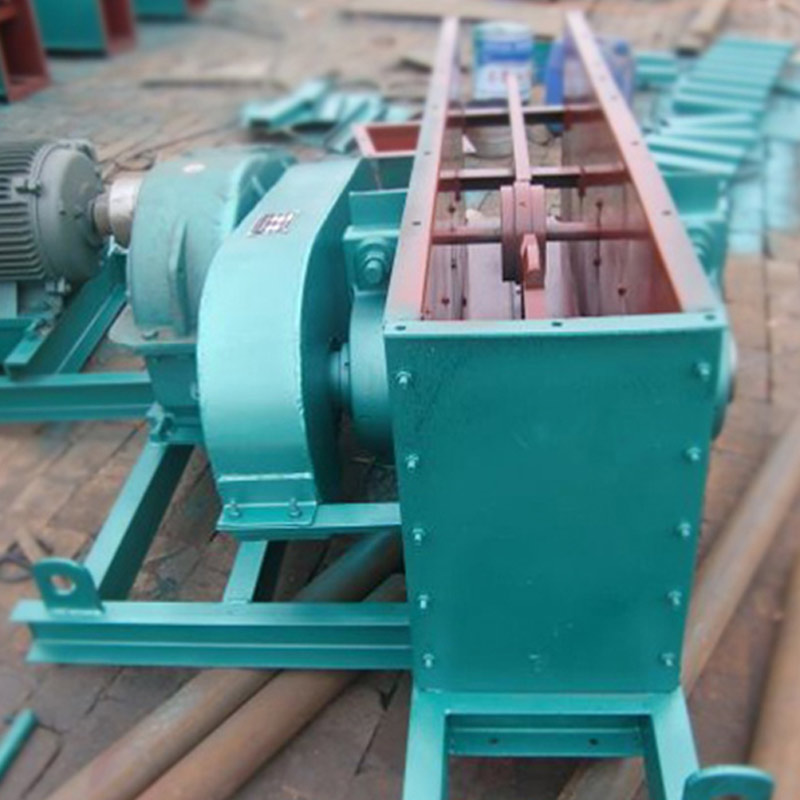

| Scraper Conveyor | With a squeegee chain traction, the conveyor that transports the bulk material in the tank is called a scraper conveyor. KS Scraper Conveyor Scrape... | |

| Dust Collector Accessories | Dust collector accessory kitinclude cloth bag for bag filter, skeleton (bag cage), electromagnetic pulse valve, pulse controller, star-type unloadi... |

Похожие товары

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | Продавец: XIUCHENG RFID | Size:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transf... | |

| Micronized wax used for industrial paint processing | Продавец: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... | |

| Fungicide Supplier | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Fungicide Supplier | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... |