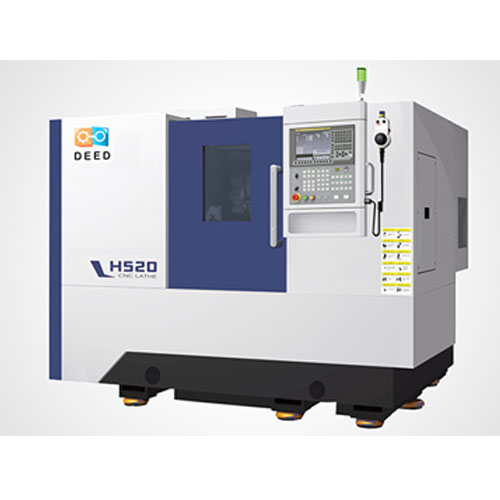

UNIVERSAL HORIZONTAL LATHE

The machine tool adopts the mainstream oblique bed structure of Europe, America, and Japan, with integrated electromechanical, hydraulic, and gas design, compact structure, and strong operability. The sheet metal adopts a fully enclosed protective structure with good chip removal, drainage, and leakage effect.

FEATURES OF UNIVERSAL HORIZONTAL LATHE

The mineral-cast rectangular hard rail bed has good shock resistance, low thermal sensitivity coefficient, and good overall rigidity.

The mineral casting spindle box has low vibration, high speed, and high efficiency, which is about 30% higher than the market average efficiency.

According to industry requirements, imported spindle units are specially ordered.

The chip conveyor is separated from the water tank, making cleaning and maintenance more convenient.

The main processing objects are the rough and fine turning of the common 12-22 inch passenger wheel hubs and the car's wheel hubs, it can also be used for the turning of similar disc parts.

WORKING PRINCIPLE OF UNIVERSAL HORIZONTAL LATHE

The working principle of the cnc lathe machine turning: The main function of the braking device of the CNC horizontal lathe is to be used in the parking process of the lathe, to overcome the rotational inertia of the moving parts in the headstock, to control the spindle to quickly stop rotating to shorten the auxiliary time and thus to horizontal The purpose of the lathe to install the brake.

As one of cnc machining center manufacturers, DEED has a complete set of independent research and development production equipment and technology and has obtained many national patents at present.

UNIVERSAL HORIZONTAL LATHE SPECIFICATION

HP800-WC

|

Feed |

φ850 |

|

|

22" |

||

|

12" |

||

|

X-axis travel |

﹣30~370 |

|

|

Z-axis travel |

850 |

|

|

X/Z axis rapid traverse feed |

20/20 |

|

|

Spindle |

Spindle speed |

2500 |

|

spindle motor power |

30/37 |

|

|

spindle torque |

375 |

|

|

spindle nose specification |

A2-8 |

|

|

spindle diameter |

φ160 |

|

|

ATC |

tool station |

8 |

|

inner tool diameter size |

φ50 |

|

|

32*32 |

||

|

adjacent tool change time |

||

|

screw |

X-axis |

φ50*P10 |

|

Z-axis |

φ50*P10 |

|

|

Accuracy |

positioning X |

|

|

positioning Z |

||

|

Repeatability X |

||

|

Repeatability Z |

||

|

Others |

X/Z axis servo motor power |

4/4 |

|

X/Z axis servo motor torque |

22/22 |

|

|

X/Z axis servo motor max. speed |

3000 |

|

|

cooling water tank capacity |

600 |

|

|

Size |

4169*2150*2147 |

|

|

Weight |

11 |

|

|

control system |

FANUC 0i-TF |

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| HORIZONTAL TURNING CENTER SPECIAL FOR WHEEL HUB | The machine tool bed adopts "mineral casting" material and technology of Germany, which guarantees DEED CNC machine tool with better performance on... | |

| CNC MACHINING INDUSTRY | Deed CNC is a top CNC machining industrymanufacturer in China, we can offer you the following services and machines: CNC machining industry part... | |

| GMC-SERIES GANTRY MACHINING CENTER | GMC series gantry mill for sale is the latest precision gantry boring and milling machining center jointly developed by Germany and DEED. The machi... | |

| VMC-SERIES VERTICAL MACHINING CENTER | As a vmc machine manufacturing company, DEED vmc cnc-series Vertical Machining Center is mainly suitable for processing complex parts such as plate... | |

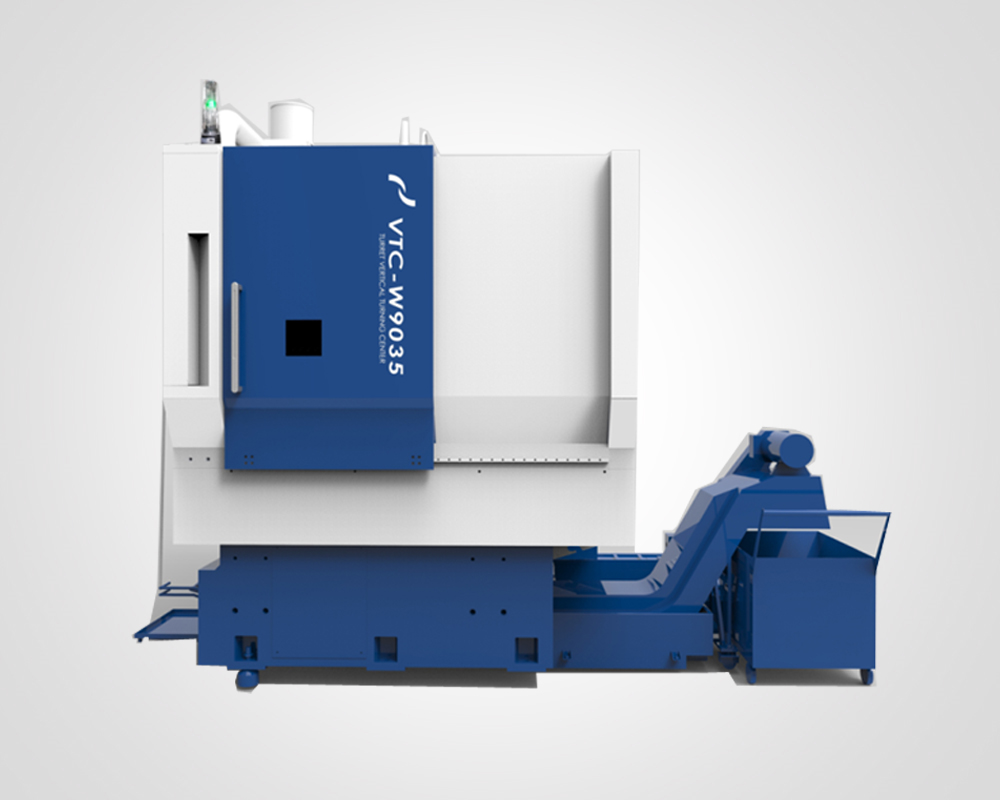

| VERTICAL TURNING CENTER SPECIAL FOR WHEEL HUB | This cnc vertical turning machine tool takes the common 14-26 inch Kaba wheel hub rough and fine turning as the main processing object and has the ... |

Похожие товары

| YC160W Wheel excavator YC160W | Продавец: Guangxi Yuchai Equipment Technology Co., Ltd | YC160W Wheel excavator YC160W wheel excavator is a new generation of full hydraulic wheel excavat... | |

| Yuchai U20 mini excavator | Продавец: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai U20 mini excavator Improvements in Over 80 Details: Tailless Excavator U20 is a Yuchai ... | |

| Yuchai YC80 small excavator | Продавец: Guangxi Yuchai Equipment Technology Co., Ltd | Yuchai YC80 small excavator International brand engine It is equipped with Yanmar 4TNV98C natur... | |

| Top Type Hydraulic Breaker | Продавец: Guangxi Yuchai Equipment Technology Co., Ltd | Top Type Hydraulic Breaker With the higher restriction of blasting control,hydraulic breakeris w... | |

| S35-Electric Skid Steer Loader | Продавец: Guangxi Yuchai Equipment Technology Co., Ltd | S35-Electric Skid Steer Loader Yuchai S35 Electric Skid Steer Loaderis compact and flexible, des... |