Liner

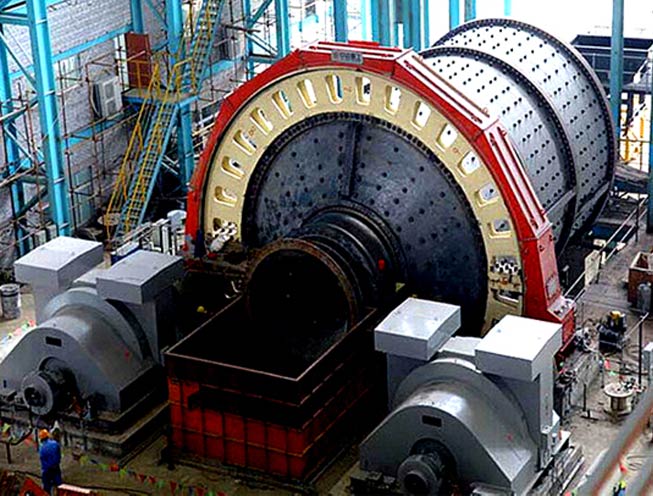

Liner is to protect the shell from direct impact and friction of grinding materials and is also used to modulate the motion of grinding material. It could improve grinding efficiency and productivity, as well as reduce liner wear. CIC's milllinersspread all over the world along with CITIC's mills. For years, CIC's manufacturing ability is not only embodied in the supplying of mill liners for certain mills with the detailed specification but also especially in the on-site mapping, model changing and efficiency improvement.

Introduction of Liner

CIC is a leading comprehensive ball mill linersupplier in China. For years, CIC's wear resistant linerspread to all over the world along with CITIC's mills. With the property of leading technology and unique expertise, lower cost and higher availability, CIC's liner has won high approval from the customers.

CIC's manufacturing ability is not only embodied in the supplying of mill liners for certain mills with detailed specifications but also, and especially in the on-site mapping, model changing and efficiency improvement. CIC has the ability to offer solutions for all kinds of mills, such as cement mill, mine mill, ball mill, rod mill liners for rod mill, AG mill, SAG mill, etc.

With several decades of development, CIC has become the Manufacturing Base of Liner of Semi-autogenous mills.

Optimizing Manufacturing Process, Guarantee Liner Quality

Our high-quality liners manufactured by the advanced process have covered the wide marketing of semi-autogenous mills.

Optimizing Liner Design, Eliminating Break of Liner

A main working function of the liner is to lift the milling ball to a reasonable height, then fall along with the right rack and smash against the material enrichment area at the bottom of the mill in order to crush the material effectively. So it is greatly important to reasonable optimizing the liner design and correct guiding the milling ball running track in order that guarantees the optimized operation condition in the mill and effectively protects the shell liner of the semi-autogenous mill, meanwhile, can eliminate liner break, prolong the service life and decrease effectively unit wear of ball mill liner and ball mill miningball, and improve the hour production per machine.

Focusing on Detailed Operating Condition, Improving Users' Benefits Optimizing

The liner design based on the wear forms of liners in different operating conditions maximally decreases the crashing function of the liners and effectively decreases the weight of scrap liners. Improving the shape of liners can effectively improve the relative motion state between milling balls and liners, then decrease liner wear by material and milling balls and prolong the liner service life while reducing the users' production cost.

Star Products

With better performance and property than the common ag mill liners, low carbon martensite alloy steel and chromium-molybdenum steel mill liners have a unique chemical composition and super mechanical properties which won a great reputation from the final users.

Design Experience in Liner

In order to optimize material, structure and techniques, as well as to extend liner life, improve efficiency and reduce the cost, we will use the simulation casting software (MAGMA, Intecast CAE), discrete element method (DEM), finite element method (ANSYS) and 3D CAD (Solid Works) to carry out model selection and design.

Our design experience mainly lies in

64 years of experience in mining machinery.

Various types of mill liners design & reform.

Ability to convert national and international standards.

Life-cycle service conception & ability.

Production technics design

Features:

Material: High Manganese Steel, Super-High Manganese Steel, High Chromium Casting Iron, Alloy Steel, Chromium-molybdenum Steel, Low Carbon Steel, or as per the customer requests.

Hardness: as per your request.

Impact Value: as per your request.

Tensile Strength: as per your request.

Heat Treatment Process: Normalizing, Tempering, Quenching & Tempering.

Surface treatment: rust preventive oil, or as per your requests.

Process: raw material purchasing - casting- rough machining - heat treatment - semi-machining - finish machining - painting and packing. Various process conditions are available.

Standard: ANSI, API, ASTM, BSI, DIN, GB, ISO, JIS.

QA and DOC: Chemical Composition Report, Mechanical Properties Report, SpheroidizatioRate Report, UT Report, PT Report, Heat Treatment Report, Dimensions Check Report, Hardness Report, etc.

Quality Control: UT Test, MT Test, Visual Inspection, Third Party Inspection, Customer On-site Inspection.

What Kinds of Liners Production Equipments Do We Have?

* 5T, 12T, 30T smelting furnaces

* VRH molding production line

* 2x5m Auto control gas heat treatment furnace

* 2x5m Auto control gas heat treatment furnace for tempering

* 1.3x1.6m Medium temperature electric heat treatment furnace

* 350T brine quenching pool

* 50T water-based quenching cooling system

Our annual production capacity of wear-resistant castings can reach 10000 tons.

Quality Control

64 years of experience accumulation and cultural heritage from Luoyang Mining Machinery Factory(CITIC nowadays)

Perfect equipment management experience.

Complete Inspection standards —— before production-after production, test and report in all links of production, finished product quality acceptance.

Experience in QC and delivery to international famous companies.

Package and Delivery

As one of heavy machinery manufacturers, we can offer kinds of related products for sale, if you have needs, please contact us.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| CIC Customized and Intelligent Equipment in Cement Industries | As a kind of building material, cement is widely used with large demand and fierce competition in the industry. As the leader of cement producti... | |

| SAG Mill | Semi autogenous grinding millor SAG mills as they are often called, can perform grinding operations equivalent to two or three stages of crushing a... | |

| CIC Mining And Cement Equipment | CIC's heavy equipment and machineryinclude not only market-leading standardized products, but also customized products and related services accordi... | |

| Vertical Centrifuge | The vertical centrifuge machineis made up of the screen which diameter range from 700 to 1,000 mm, the rotor body (including the blade), transmissi... | |

| Wet Grid Ball Mill | Wet Grid Ball Mill Wet ball millis a kind of energy-saving industrial grinding mill which adopts rolling bearings and has high efficiency. Wet g... |

Похожие товары

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | Продавец: XIUCHENG RFID | Size:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transf... | |

| Micronized wax used for industrial paint processing | Продавец: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... | |

| Fungicide Supplier | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Fungicide Supplier | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... |