plastic bucket mould Company

Designing and manufacturing a plastic bucket mould requires a comprehensive understanding of the intricacies involved in the process. Whether for household, industrial, or commercial use, plastic buckets serve diverse purposes, demanding moulds that can produce durable, precise, and efficient products. Addressing the numerous challenges involved necessitates a careful examination of materials, design intricacies, cooling systems, surface finishes, and maintenance protocols.

Material Selection:

The choice of materials for a plastic bucket mould plays a pivotal role in determining its durability and performance. Typically, moulds are crafted from high-grade steel alloys, such as P20, 718, or H13, due to their excellent wear resistance and longevity. These materials endure the rigors of the injection molding process, ensuring the mould sustains its integrity over numerous cycles. Additionally, the proper selection of materials minimizes the need for frequent replacements, enhancing the overall cost-efficiency of the manufacturing process.

Design Precision:

Precision in design is paramount when it comes to plastic bucket moulds. Engineers meticulously create mould cavities that mirror the exact specifications of the final product. Each curve, contour, and dimension is calculated with precision, leveraging advanced software tools to optimize the design. The goal is to ensure that every plastic bucket produced is uniform in size, shape, and thickness. By integrating cutting-edge computer-aided design (CAD) technologies, manufacturers can achieve the level of accuracy necessary for high-quality plastic bucket production.

Efficient Cooling Systems:

Efficient cooling systems are critical to the plastic bucket moulding process. Proper cooling ensures uniformity in the cooling rates, preventing deformities in the final product such as warping or shrinkage. Engineers strategically integrate cooling channels within the mould design, allowing for optimal heat dissipation. By employing advanced techniques like conformal cooling, where cooling channels follow the contours of the mould, manufacturers can significantly reduce cycle times and enhance productivity without compromising the quality of the plastic buckets.

Surface Finishes:

The surface finish of plastic bucket moulds directly impacts the appearance and texture of the final product. A smooth and polished mould surface ensures that the plastic buckets produced are free from blemishes and imperfections. Techniques such as polishing, texturing, and coatings are employed to achieve the desired surface finish. A flawless surface not only enhances the aesthetic appeal of the plastic buckets but also contributes to their functionality and ease of use.

Maintenance Protocols:

Regular maintenance is crucial to prolonging the life of a plastic bucket mould. Proper cleaning, lubrication, and inspection routines are established to prevent wear and tear. Timely maintenance not only extends the mould's lifespan but also ensures the consistent quality of the plastic buckets. Additionally, implementing a robust quality control process, which includes stringent inspection of the moulded plastic buckets, helps identify any defects or deviations from the specified standards. This proactive approach allows manufacturers to address issues promptly, maintaining the high quality of the end products.

Advanced Manufacturing Technologies:

Advancements in manufacturing technologies have revolutionized the plastic moulding industry. Additive manufacturing techniques, such as 3D printing, enable rapid prototyping, allowing engineers to test and refine designs before full-scale production. Computer simulations and mold flow analysis tools provide valuable insights into the moulding process, enabling manufacturers to optimize designs for efficiency and precision. By embracing these technologies, manufacturers can stay at the forefront of innovation, producing plastic bucket moulds that meet the evolving demands of the market.

In conclusion, designing and manufacturing a plastic bucket mould that meets the highest standards of quality and efficiency requires a holistic approach. Material selection, design precision, efficient cooling systems, surface finishes, maintenance protocols, and the integration of advanced manufacturing technologies are all vital components of this process. By meticulously addressing each of these aspects, plastic bucket mould manufacturers can produce plastic bucket moulds that not only meet but exceed customer expectations, ensuring the production of durable, precise, and high-quality plastic buckets for various applications.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| AUSTRALIAN TYPE DISPOSABLE PS PLASTIC VAGINAL SPECULUM | cn-shengbo.com Item No. & Description SY006 Disposable Vaginal Speculum(AustralianType) Material PS Specification M / S Fe... | |

| 300D Linen Type Cationic Fabric | 300D linen is a type of fabric made from linen fibers that have been twisted together to create a durable and strong material. The "D" refers to th... | |

| High Quality transparent moon cake boxes | Transparent moon cake boxes represent a fusion of tradition and modernity, encapsulating the essence of meticulous craftsmanship and contemporary p... | |

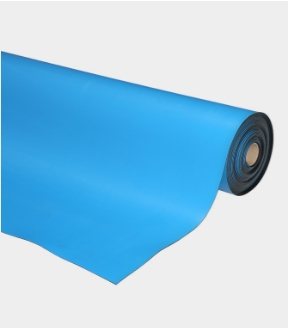

| Foam Anti-Static Table Mat: Safeguarding Electronics from Electrostatic Discharge | In the ever-evolving world of technology and electronics, the protection of sensitive electronic components is of utmost importance. Electrostatic ... | |

| body analyzer scales Company | Body analyzer scales have become increasingly popular as people are becoming more health-conscious and seeking effective ways to track their fitnes... |

Похожие товары

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | Продавец: XIUCHENG RFID | Size:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transf... | |

| Micronized wax used for industrial paint processing | Продавец: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... | |

| Fungicide Supplier | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Fungicide Supplier | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... |