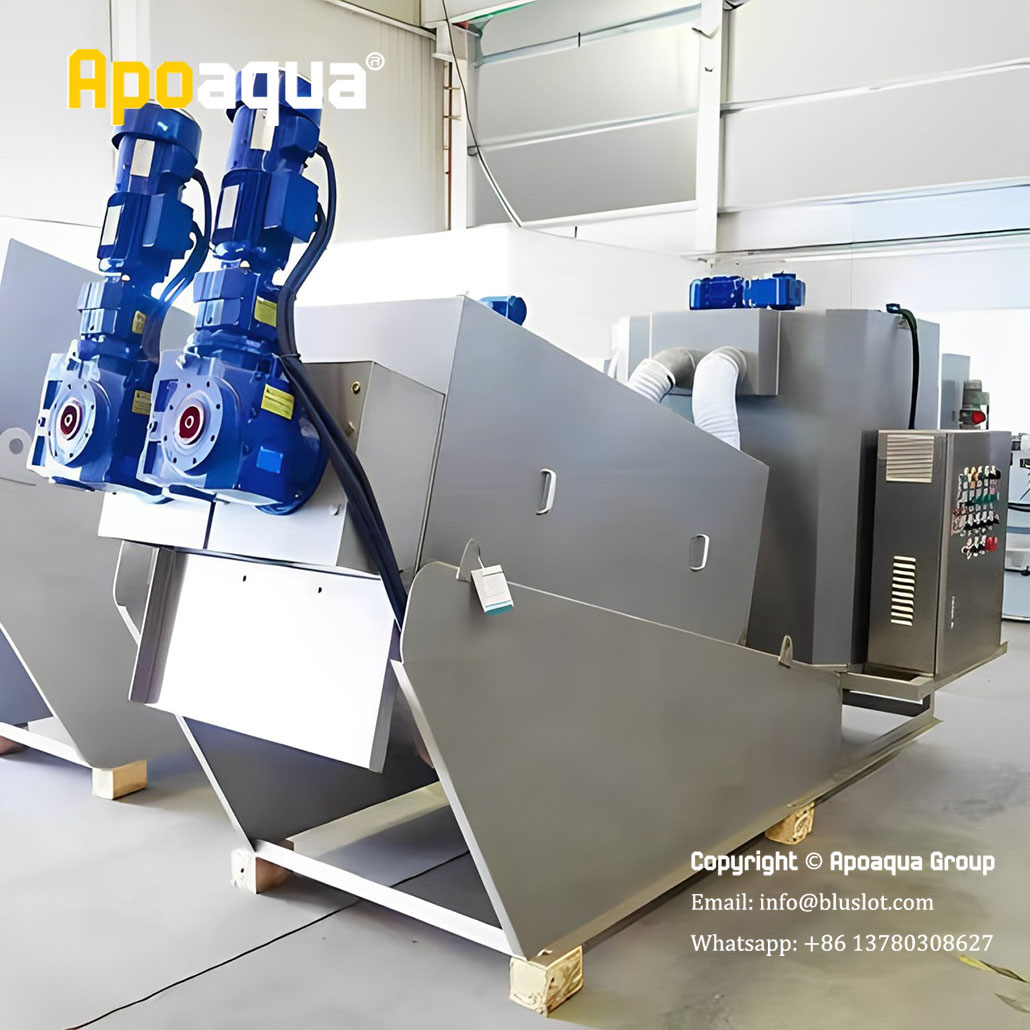

Apoaqua Dewatering Screw Press Machine for Plastic Factory Wastewater

Apoaqua's sludge dewatering machine can be used in the sludge treatment process of plastic pellet plants.

Plastic pellet factories will inevitably produce wastewater during the production process, which mainly comes from the cleaning and cooling process of plastic pellet production.

Plastic particle wastewater is one of the main sources of pollution in the production process of the plastics industry. It contains high concentrations of suspended solids, organic matter and toxic substances. If these sewage are discharged directly without proper treatment, it will cause serious pollution to the environment and affect the ecological balance and human health. Therefore, it is crucial to treat the wastewater from plastic pellet plants.

Apoaqua's dewatering screw press plays an important role in plastic pellet sludge treatment.

In addition to providing dewatering screw press production services, we also provide corresponding mechanical grille equipment to ensure the normal operation of the entire system.

Why Choose Sludge Dewatering Machine?

The operation process of the sludge dewatering screw press is relatively simple and intuitive. Compared with plate and frame filter press, there is no need for complicated filter cloth installation and replacement process. After each operation cycle of the plate and frame filter press, the filter plates need to be manually removed and the filter cloths cleaned. This is not only time-consuming and labor-intensive, but also the operation process is cumbersome and prone to errors. Especially when treating wastewater in plastic pellet plants, the fully automatic operation mode will greatly reduce the operating costs of the equipment.

The sludge dewatering equipment uses a unique screw extrusion principle and has a high degree of automation. The operator only needs to perform simple settings and monitoring, and the equipment can run stably, which greatly reduces the difficulty of operation and the requirements for the operator's skill level.

In addition, the sludge dewatering machine requires almost no artificial consumables during operation. Its unique structural design and working principle enable the equipment itself to operate stably for a long time. There is no need to frequently replace parts or add additional materials, significantly reducing operating costs.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Wedge Wire Cylindrical Screen Basket for SEPCOM Screw Press Separator | Wedge wire screw press filter screen is mainly used in the application of dewatering manure in farms. It is a simple, slow moving mechanical device... | |

| Apoaqua Sludge Dewatering Machine for Pig Farm | Apoaqua pig manure sludge dewatering screw press for sale. In the livestock industry, manure wastewater is a vexing problem. Apoaqua's dewatering ... | |

| Screw Press Dewatering Machine for Hospital Wastewater | With the continuous development of medical technology, the amount of sewage generated by hospitals is increasing. Screw press dewatering, as an eff... | |

| Brewery Sludge Dewatering Machine System for Sale | Sludge dewatering machine is widely used in breweries. It can improve water quality, reduce energy and material consumption, reduce pollutant emiss... | |

| Apoaqua Dewatering Screw Press Machine for Raw Water Pretreatment | Apoaqua's sludge dewatering machine can be used for sludge treatment in power plants. A large amount of sludge will be produced during raw water pr... |

Похожие товары

| Micronized polypropylene wax for injection moulding | Продавец: Syntop chemical Co.,Ltd. | The incorporation of polypropylene micronized wax into injection moulding processes delivers the ... | |

| Drum Type Mobile Mixing Station | Продавец: Yousheng Machinery Equipment Co.,Ltd | Drum Type Mobile Mixing Station Drum Type Mobile Mixing StationPortable Drum Concrete Batch Plan... | |

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | Продавец: XIUCHENG RFID | Size:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transf... | |

| Micronized wax used for industrial paint processing | Продавец: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... |