Agricultural and Sideline Products Deep Processing

Advanced crop process engineeringmachinical types of equipment, testing instruments, sophisticated manufacturing production technology in agriculture, and strict & perfect quality management system. Hongvadar agricultural product processing held the ISO9001 quality system certification. Most science & technology teams with professional production technology in agriculture. Leading level of science to make full use of the new processes, new technology, new materials to ensure the stability and reliability of products in agriculture step by step process.

Agricultural Products Processing and StorageEquipment

Fluid Bed Dryer System

Fixed fluidized bed dryer effectively reduces the dust leakage in the soft connection part of agricultural food processing, improves the production environment, reduces the equipment failure rate, and reduces the civil construction investment.

High efficiency. First-in-first-out, effective prevention and control of product color difference.

Spray Granulation Fluidized Bed Drying System

High density, uniform moisture, high strength, good sphericity, not easy to absorb moisture, good fluidity, and other characteristics of dry products.

No dust, no peculiar smell, vacuum operation, and clean site environment during granulation and drying process of agricultural production process.

Energy recycling and utilization, low energy consumption.

Continuous Evaporative Crystallization System

Suitable for the products in farm produce processingwith general requirements on crystal shape and size, and with high concentration discharging.

Various evaporative crystallization systems can be designed according to the characteristics of materials and the evaporation capacity.

Continuous feed, continuous discharge.

Relatively low temp. evaporation, fast evaporation speed, high evaporation concentration, and the relatively high viscosity of the liquid material are not easy to scale or block, which can achieve the maximum crystal ratio under the same energy consumption.

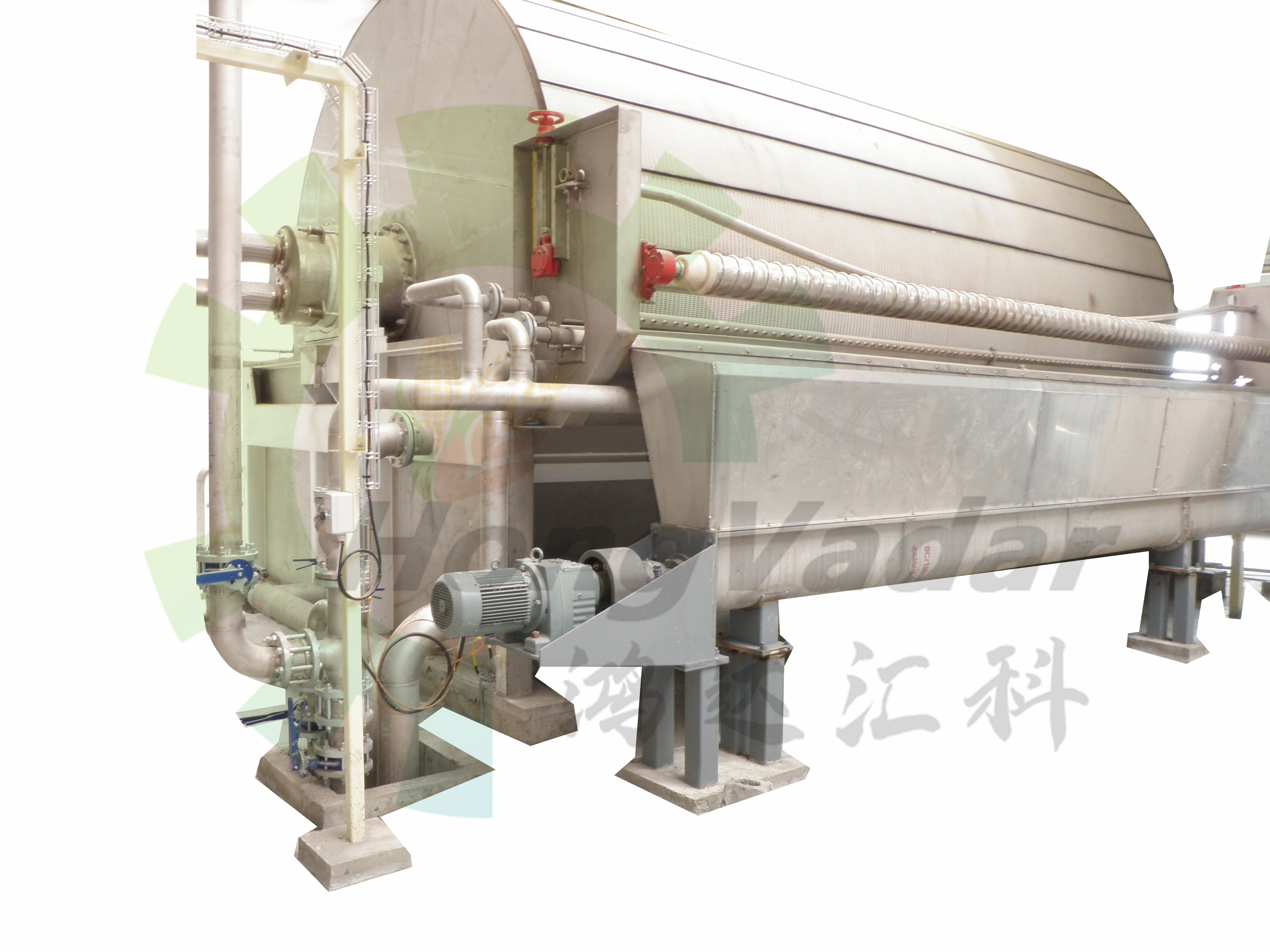

Rotary Vacuum Filter

Personalized design to meet the needs of different customers;

High production capacity, low wet of filter cake, easy to unload;

Continuous automaticand simple operation in agricultural products processing and storage;

The high clarity of filtrate and high recovery rate of materials .

Evaporator System

Running stably, highly efficient and energy-saving & low steam consumption.

High concentration ratio in food processing of agricultural products

Low evaporation temp, suitable for the concentration of heat-sensitive materials.

High separation effect and greater flexible operation

Arc Screen

High production capacity

Good screening effect

Safe and reliable use

Compact structure and reasonable configuration

Bundle Dryer

Wide range of drying materials

Large moisture evaporation

Low energy consumption

Easy operation and convenient maintenance

Air Dryer System

High heat transfer coefficient, can continuously dry large number of materials.

Fast drying speed, good material quality.

Energy saving and low consumption in food processing of agricultural products

Easy operation, small area needed, and low investment.

Desand Cyclone and Germ Cyclone

Advanced design

Easy installation

Large production capacity range

Compact structure and reasonable configuration

Squeezer & Extruder

Continuous production with high dehydration efficiency in processing of farm produce

Simple structure, easy to use and maintain.

Compact structure, small floor space, and convenient transportation.

Stable running and low failure rate.

Squeezer & Extruder

Continuous production with high dehydration efficiency in processing of farm produce

Simple structure, easy to use and maintain.

Compact structure, small floor space, and convenient transportation.

Stable running and low failure rate.

Degerminator/Degerm Mill

Degerminator/Degerm Mill

VIEW MORE

Good grinding effect.

Stable running and low failure rate.

Easy operation and convenient maintenance.

Compact structure and reasonable configuration.

Pin/Needle Mill

Good milling effect.

Compact structure and reasonable configuration.

Short process route.

Large production capacity.

12-stage Hydrocyclone System

Good washing and refinery effect.

Stable running and low failure rate.

Easy operation and convenient maintenance.

High production capacity.

Peeler Centrifuge

Fully automatic operation with low manual labor intensity;

Each actuator adopts a hydraulic system for automatic control, stable and reliable operation;

Electric adopts PLC control, accurate movement, convenient adjustment;

Drive-by VFD or hydraulic coupler, smooth start and stop.

Disc Separator

Large rotary drum diameter, large disc area, strong processing (separation) ability, the good separation effect;

Using the upper suspension drive, so that the separator has a high degree of rotation stability, and greatly improved the service life of the bearing and spindle;

Automatic control of lubricating oil circuit is adopted to protect the driving system and extend the service life of the driving system;

Liquefaction System

High efficiency and high conversion rate.

Automatic intelligent control, stable production and low labor cost.

Better flocculation effect of the protein, which is conducive to the subsequent process and the separation of the protein in crop process engineering.

Easy operation and convenient maintenance.

Saccharification System

High saccharification efficiency.

Automatic intelligent control, not easy to stain.

Accurate saccharification, not easy to produce other miscellaneous sugars in crop production processing.

Taking side agitator, low energy consumption, even mixing and good mixing effect.

Full Automatic Intelligent Ion Exchange System

Serial column desorption, low concentration to push high concentration, solves the problem of washing water strip.

Column regeneration makes the regenerator fully utilized and reduces the consumption of the regenerator.

Column washing reduces the amount of washing water and reduces the discharge qty. of sewage.

Chromatography System

High purity product, stable running and low failure rate.

Best separation effect and high production yield.

Low water consumption and low energy consumption.

Automatic intelligent control with low labor cost.

Membrane Filter System

Intelligent control, stable running and low failure rate.

Easy operation and convenient maintenance.

Compact structure and reasonable configuration.

High production capacity.

Isomerization System

Easy to install and save equipment compared with traditional equipment.

High operation accuracy, high speed and high efficiency. Use control instrument for operation control to ensure accurate and high quality products.

PLC operation is convenient and production is stable.

High production capacity.

Spray Dryer System

Fast drying speed, only a few seconds to complete.

Suitable for drying heat-sensitive materials.

Wide range of use.

Simplified production process and easy operation & control.

Crystallizer

Horizontal Crystallizer.

The transmission device has a compact structure, stable operation, high efficiency, and low noise.

Reliable mechanical seal, shortstop time.

The small gap between the spiral belt and the barrel body, uniform stirring, not blocked.

Stainless steel inner cylinder, corrosion resistance, long service life.

Centrifuge

Automatic control to ensure the separation effect.

Stepless speed regulation.

Wide speed range.

Large starting and braking torque.

Filter Press

The upper part of the main beam is covered with 304 stainless steel, which can effectively reduce the friction resistance between the filter plate and the main beam and reduce the working strength;

Filter plate adopts new raw materials and formula, high pressure molding, high strength, high working pres, high filtration efficiency, no blocking, no breaking plate, with high strength, light weight, high temp. resistance, corrosion resistance, acid and alkali resistance, non-toxic, tasteless and other characteristics;

Equipped with a variety of safety devices to ensure the safety of operators, simple operation, convenient maintenance;

It optional equipped with PLC control, automatic plate shifting, automatic unloading, automatic drip tray, diaphragm pressing, open flow or dark flow, washing/blowing mode, high temp. resistance of filter board, etc.

If you want to know more about cassava starch processing line, please contact us.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Degerminator/Degerm Mill | HongVadar company provides you the Lysine, Tryptophan, Threonine, Valine, Leucine, etc. fermentation products project. HongVader as agricultural pr... | |

| Air Dryer System | HongVader as agricultural processing plants play the roles of corn, sweet corn processing plant, potato processing plant, starch of corn and wheat ... | |

| Air Dryer System | HVD-AD-P series air dryer in pneumatic systemunit is composed of an air heater, air filter, disintegrating disc, thrower, venturi pipe, air drying ... | |

| Rotary Vacuum Filter | Pre-coating Vacuum Filter System HVD-PVF-P series pre-coating vacuum filter works on the same principle as the general rotary vacuum filter in sug... | |

| 12-stage Hydrocyclone System | VD-HC-D series 12 stage starch washing hydrocyclone systemis mainly used to extract refined starch milk, that is, to remove soluble and insoluble p... |

Похожие товары

| FMS888-1S Stainless Steel Industrial Box Change Locks | Продавец: Ningbo Oubao Technology Co., Ltd. | Материал: база из нержавеющей стали, ручка, крышка, вращающийся вал, стальный болтПоверхностная... | |

| Устойчивая дышающая искусственная синтетическая кожа для украшения интерьера | Продавец: Fu\\\'an Synthetic Materials Co.,Ltd. | Эта износостойкая дыхающая искусственная синтетическая кожа для украшения интерьера изготовлена и... | |

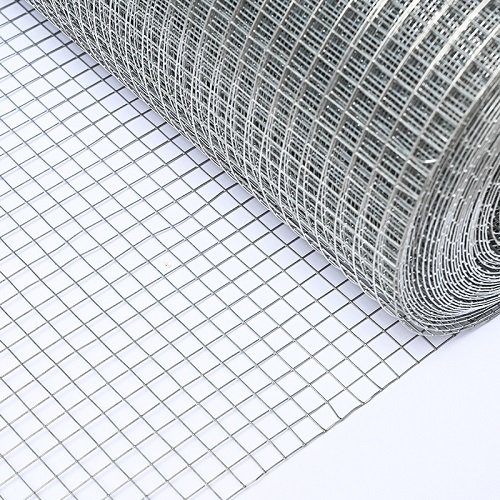

| Welded Wire Mesh Net | Продавец: Jiaohao Wire Mesh Products Co., Ltd. | Constructed by fusing metal wires at their intersection points, welded wire mesh panels are made ... | |

| Steel Grating | Продавец: Jiaohao Wire Mesh Products Co., Ltd. | Made from carbon steel, stainless steel or hot-dip galvanized steel with a galvanized surface tre... | |

| Chain Link Fence | Продавец: Jiaohao Wire Mesh Products Co., Ltd. | Chain link fence also known as cyclone fence, it is an elastic woven net. Thiswire mesh productis... |