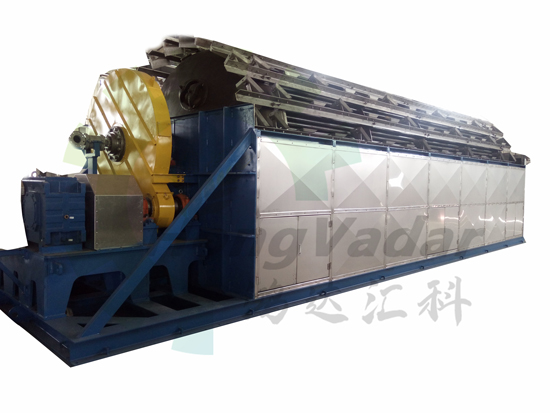

Fluid Bed Dryer System

HVD-FBD-P series boiling fluidized bed dryer takes air heated by the heat exchanger to form hot air which is distributed into the main engine through valve plate, and the loose wet material is transferred into the fbd dryer from the feeder. Due to the effect of wind pressure, the material forms a boiling state in the dryer and has extensive contact with hot air, thus drying the material in a relatively short time. Fluid dryer bed is suitable for drying bulk materials and crystal materials; After drying, the product has the characteristics of uniform moisture, good fluidity, and not easy to agglomerate, which is widely used in amino acid, food industry, and other materials drying. As the fluid bed dryer suppliers, HongVadar provides high quality fluid bed dryer for sale. Compared with other manufacturers, we can offer a reasonable fluid bed dryer price.

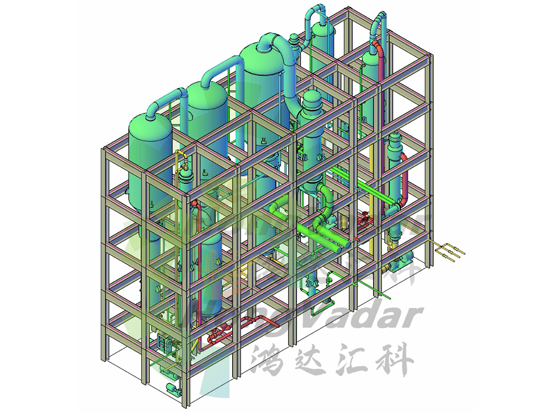

System Optimization and Energy Saving Scheme

lOur industrial fluid bed dryer manufacturertakes the patent technology to improve the structure of the air distribution system of the fluidized bed dryer, and improves the traditional vibrating fluidized bed into a fixed fluidized bed, which improves the temperature difference between hot air and the utilization ratio of hot air, and effectively reduces the energy consumption level of the system.

lHongVadar industrial fluid bed dryer manufacturer adopts the fixed fluidized bed dryer effectively reduces the dust leakage in the soft connection part, improves the production environment, reduces the fluid bed drying equipmentfailure rate, and reduces the civil construction investment.

lFluid bed dryer manufacturer optimizes the design of all the fluid bed drying equipments and pipes of the ventilation system to reduce the resistance of each equipment and pipe to the wind, reduce the installed power of blower and induced draft fan, and save the electricity consumption.

lAccording to the gravity principle and trapezoidal distribution, make full use of high and low gravity difference, reduce the power transmission equipment, reduce installed power, and save electricity consumption.

lThe finned heat exchanger of fluid bed drying equipment is a self-designed and developed high-efficiency energy-saving heat exchanger, which can make maximum use of the heat of condensate water and flash steam generated.

lIndustrial fluid bed dryer manufacturer utilizes the proprietary technology to realize the average distribution of materials as soon as possible, fully mix with the materials in the dryer, and adopt the patented technology of directional side blowing air plate to realize the first-in-first-out of materials; Effective prevention and control of product color difference.

lFor the phenomenon that the product is easy to absorb moisture and agglomerate after packaging due to high air humidity, add a cooling and dehydrating device like fluid bed drying equipment cooler in the cold air conveying pipe to dehumidify the air and cool the product with the drying cold air.

lThe directional side blowing air plate and no dead angle treatment of the internal components, can clean all the materials in the fluid bed drying equipment when the machine is shut down, reduce the manual cleaning process, and prevent the risk of bacterial contamination and mildew of the remaining materials.

Fluid Bed Dryer System Feature

lEnergy-saving and low consumption. High efficiency.

lFixed fluidized bed dryer effectively reduces the dust leakage in the soft connection part, improves the production environment, reduces the equipment failure rate, and reduces the civil construction investment.

lFirst-in-first-out, fluid bed drying equipment has effective prevention and control of product color difference.

lOur fluid dryer bed has many features, for example, the continuous or batch fluid (fluidized) bed dryer,vibrating fluid (fluidized) bed dryer, horizontal fluidized bed dryer, aeromatic fluid bed dryer and carrier fluid bed dryer.

HongVadar is a advanced industrial fluid bed dryer manufacturer relies on professional design, strict production management, the fine processing procedure to provide high efficiency and energy saving fluid bed drying equipment system for the customer. The industrial fluid bed dryer manufacturer has passed the international ISO9001 quality system certification, and with the design and manufacturing capacity of pressure vessels. Customers can choose Chinese GB, International ISO, American standard AWS, EU EN, and other standards for equipment design and production according to their needs. Compared with other fluid bed dryer suppliers, Hongvadar fluid bed dryer chinahas fluid (fluidized) bed dryer of affordable price for sale.

Fluid Bed Dryer System Technical Parameter

|

Model |

EV capacitykg/h |

Steam consumption, kg/h |

Drying area(m2) |

PowerKw |

Installed dimension (mm) |

||

|

L |

W |

H |

|||||

|

HVD-FBD1.0-P22 |

65-110 |

140-200 |

1 |

22 |

6000 |

3000 |

4200 |

|

HVD- FBD2.0-P37 |

125-210 |

260-320 |

2 |

37 |

6500 |

3000 |

4400 |

|

HVD- FBD3.0-P45 |

180-300 |

420-480 |

3 |

45 |

7000 |

3600 |

4500 |

|

HVD-FBD4.0-P55 |

210-420 |

510-650 |

4 |

55 |

7500 |

3800 |

4500 |

|

HVD-FBD5.0-P65 |

320-510 |

720-780 |

5 |

65 |

8200 |

4000 |

4800 |

|

HVD-FBD6.0-P75 |

430-620 |

910-950 |

6 |

75 |

8600 |

4200 |

5200 |

|

HVD-FBD7.0-P90 |

540-760 |

1100-1200 |

7 |

90 |

9000 |

4400 |

5500 |

|

HVD-FBD8.0-P110 |

620-850 |

1350-1600 |

8 |

110 |

9500 |

4500 |

5500 |

|

HVD-FBD10.0-P120 |

660-1100 |

1300-1800 |

10 |

120 |

10000 |

4800 |

5800 |

Fluid Bed Dryer Working Principle

If gas passes through a particle bed, the bed will take on a different state depending on the flow velocity. When the flow velocity is lower, the flow only passes through the gaps between the stationary particles, which is called a fixed bed. When the flow velocity increases to a certain value, all particles are suspended by the rising airflow. At this moment, the force of gas on particles is balanced with the gravity of particles, and the bed reaches the initial fluidization. At this time, the airflow velocity is called the minimum fluidization velocity. When the airflow velocity exceeds this value and exceeds the terminal velocity of particles (maximum flow velocity), the upper interface of the bed disappears and has entrainment phenomenon. Solid particles are brought out from the bed with the fluid. Such situation is the phenomenon of airslide transmission to the solid particles, or called dispersed phase fluidized bed.

Fluid Bed Dryer Definition

Fluidized bed drying technology is a new drying technology developed in recent years. The process is that the bulk material is placed on the orifice plate, and the gas is transported from the bottom of the orifice plate, causing the material particles to move on the gas distribution plate, which is suspended in the air flow and produces the mixed bottom layer of material particles and gas, just like liquid boiling. In the fluidized bed dryer, the material particles are in full contact with the gas in the mixing bottom layer for heat transfer and moisture transfer between the material and the gas. It is widely used in chemical, food, ceramics, medicine, polymer and other industries.

Application of Fluidized Bed Dryer

It is suitable for drying bulk granular materials, such as pharmaceutical drugs in the bulk drug, tablet granule material, traditional Chinese medicine; Medium agent, chemical raw materials in the plastic resin, citric acid and other powder, granular material drying dehumidification, also used in food and beverage; Medium agent, grain processing, corn germ, feed drying, as well as mineral powder, metal powder and other materials. The maximum particle size of the material can be 6mm. The best is 0.5-3mm.

Beijing Hongvadar Engineering Technology Co. Isa professional sweet corn processing plant, we provide tomato processing plant for sale, single cyclone separator, vibro fluid bed dryer for tea, vibro fluidized bed dryerand etc. Want to know construction and working of fluidized bed dryeror fluid bed dryer troubleshooting, contact us.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Arc Screen | Gravity Arc Screen HVD-AS-G series gravity screenand pressure screenis a new type of efficient static screening equipment. The screen surface is m... | |

| Liquefaction System | HongVadar company provides you the Lysine, Tryptophan, Threonine, Valine, Leucine, etc. fermentation products project. HongVader as agricultural pr... | |

| Centrifuge | HVD-TCF-P is a commercial centrifugedevice with mechanical unloading. All parts contact with the material and water, steam pipeline is made of stai... | |

| Bundle Dryer | HVD-BD-P series rotary steam tube bundle dryersystem is an indirect contact dryer. Its structure is the transmission of heating tube dryer machinew... | |

| Evaporator System | HongVadar company provides you the Lysine, Tryptophan, Threonine, Valine, Leucine, etc. fermentation products project. HongVader as agricultural pr... |

Похожие товары

| FMS888-1S Stainless Steel Industrial Box Change Locks | Продавец: Ningbo Oubao Technology Co., Ltd. | Материал: база из нержавеющей стали, ручка, крышка, вращающийся вал, стальный болтПоверхностная... | |

| Устойчивая дышающая искусственная синтетическая кожа для украшения интерьера | Продавец: Fu\\\'an Synthetic Materials Co.,Ltd. | Эта износостойкая дыхающая искусственная синтетическая кожа для украшения интерьера изготовлена и... | |

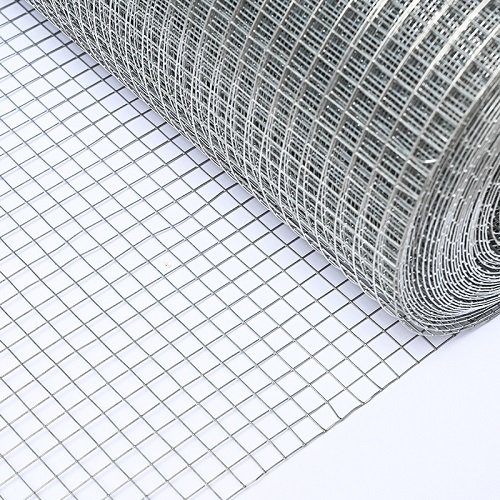

| Welded Wire Mesh Net | Продавец: Jiaohao Wire Mesh Products Co., Ltd. | Constructed by fusing metal wires at their intersection points, welded wire mesh panels are made ... | |

| Steel Grating | Продавец: Jiaohao Wire Mesh Products Co., Ltd. | Made from carbon steel, stainless steel or hot-dip galvanized steel with a galvanized surface tre... | |

| Chain Link Fence | Продавец: Jiaohao Wire Mesh Products Co., Ltd. | Chain link fence also known as cyclone fence, it is an elastic woven net. Thiswire mesh productis... |