Lees Residue Air Dryer QG/JG/Q

If you are checking lees residue air dryer qg/jg/q price, or looking for cheap high torque lees residue air dryer qg/jg/q, welcome to contact KODI Machinery, we are one of the leading China lees residue air dryer qg/jg/q manufacturers.Quick DetailsCondition: NewType: Air Stream DryerPlace of Origin: Jiangsu, China (Mainland)Brand Name: KODIModel Number: Q/QG/JG ModelVoltage: 220v-450vPower(W): 6.25-63kwDimension(L*W*H): Depends on the modelWeight: Depends on the modelCertification: IS9001,CEWarranty: 1 yearAfter-sales Service Provided: Engineers available to service machinery overseasPruduct Name: Q/QG/JG Model Lees Residue Air Flow Dryer Air Stream DrierModel: Q/QG/JGMaterial: Stainless steel , carbon steelEvaporated water: 50-1000 kg/hPower: 6.25-63 kwOccupied area: 20-120㎡Height: 9-16 mControl: PLC controlInstallation: KODI serviceSpare parts: Supply the whole lifetimePackaging & DeliveryPackaging Details:KODI Q/QG/JG Model Lees Residue air drier / Lees Residue air

dryer / Lees Residue air flow dryer is packing with plywood box or As

customers' requirementDelivery Detail:30 - 90 daysKODI Q/QG/JG Model Lees Residue Air Flow Dryer Air Stream Drier 1. Lees Residue air drier / Lees Residue air dryer / Lees Residue air flow dryer2. GMP standard3. Drying time is short 4. Big capacityProduct DescriptionWhat is Lees Residue Lees refers to deposits of dead yeast or residual yeast and other particles that precipitate, or are carried by the action of "fining", to the bottom of a vat of wine after fermentation and aging. The yeast deposits in beer brewing are known as trub. However, yeast deposits from secondary fermentation of both wine and beer are referred to as lees. This material is the source for most commercialtartaric acid, which is used in cooking and in organic chemistry.Normally the wine is transferred to another container (racking), leaving this sediment behind. Some wines (notably Chardonnay, Champagne and Muscadet) are sometimes aged for a time on the lees (a process known as sur lie),

leading to a distinctive yeasty aroma and taste. The lees may be

stirred (bâtonage in French) in order to promote uptake of the lees'

flavour.The lees are an important component in the making of Ripasso where the leftover lees from Amarone are used to impart more flavour and colour to partially aged Valpolicella.Q/QG/JG Lees Residue Air Dryer DescriptionLees

Residue Air dryer is also called as momentary dryer. At the beginning

of foundation, we began to choose the advanced technologies both at home

and provide complete equipment with high quality and cheap price to

pharmaceutical industry, chemical industry, foodstuff industry and so

on. For many years it has been developed 4 serious through unceasing

improvement and raising: Q series: basic type; QG serious: fan and

distributor type; JG serious: reinforce type. Q/QG/JG Lees Residue Air Drier FeaturesThe

dry strength is large and investment of equipment is small: the

treating amount of Lees Residue air drier is the largest. The evaporated

moisture capacity of equipment manufactured by us will be 50-1500kg/h.

The volume of equipment is small and the investment is saving. The

advantage can not be compared from other drying equipment.The

automatic degree is high and the quality of product is good: the raw

material to be dried is inside the pipe. The drying time is short (only

0.5-2 seconds) so that the automatic can be realized. The raw material

can not contact with outer substances. So the pollution is small and the

quality of product is good.The equipment will be

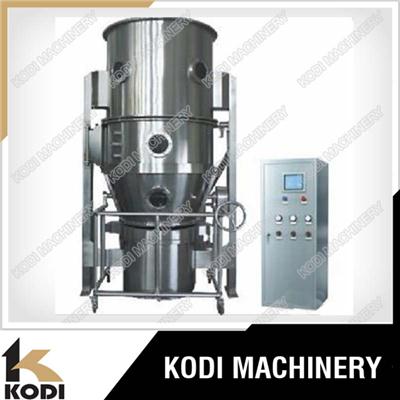

supplied completely and the heat source can be chosen freely: the air

stream dryer will be supplied completely. The basic type consists of

filter, heater, feeder, drying pipe, fan and cyclone separator. Customer

can install duster and other auxiliary equipment in accordance with

practical conditions. On the choice of heating way, air stream dryer has

a wide suitability. Customer can choose steam, electricity, and

air-heated furnace to heat in accordance with practical conditions.

Meanwhile it should be chosen in accordance with the temperature of raw

material to be resisted(of temperature of hot air): if ≤150°C, choose

steam to heat, if ≤200°C, electrical or steam and electrical as

supplement or heat conduct oil; if ≤300°C, coal air-heated furnace; if

≤600°C, oil air-heated furnace.Details of Q/QG/JG Lees Residue Air Flow Dryer Q/QG/JG Lees Residue Air Dryer Working PrincipleThe

damp raw material through conveyer and heated fresh air enters into the

dryer at the same time. They are mixed fully. Because the area of heat

exchange is large, the purpose of evaporation and drying can be realized

in a short time. The dried finished product is discharged from cyclone

separator. Small parts of powder dust can be recovered and used through

cyclone separator or bag filter. Model Q air stream dryer is operated at

negative pressure. The raw material does not pass through fan. Model

QG air stream dryer is operated at positive pressure. The raw material

passes through fan with the effect of crushing. Model FG air stream

dryer is tail air circle type. Model JQ air stream dryer is a reinforced

type. It integrates flash dry and air stream dry in one body and is

also a newest style dryer designed and manufactured by us as customer

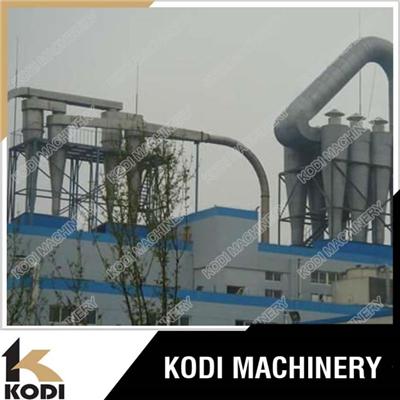

request.Q/QG/JG Lees Residue Air Flow Dryer Technical Parameters ModelEvaporated water(kg/h)Power(kw)Occupied area(m2)Height(m)Q50506.25(8.25)209QG50506.25(8.25)209JG5050 9.25(11.25)209Q1001008.6(11.6)3211QG1001008.6(11.6)3211JG10010016.1(19.1)3211Q.5)6416QG.5)6416JG.5)6416QQGJGQQGJGMaterial ExampleMaterialFeed moisture content (%)Product moisture content (%)Hot air inlet temperature /℃Exhaust gas temperature /℃Product particle size /meshAspirin2.5-50.28060Rose essenceOxalic acid4-50.51204020Sodium acetate102-380-90MSG4-50.1100Medicinal baking soda30.05110Sodium sulfite5-60.0510040Glucose16-179.1904020Wheat starchTight sand4-50.570-9050Corn starchNH60.5 below140-15050Stearic acid saltSodium silicate121 below400160Benzoic acid250.51106080Sulfonated coalinlet)Ammonium sulfate1.8-2.50.02-0.Sulfoammonium(SN.5Nitrogen based phenol100.424070Starch42.912.7147.638.20.05Activated carbon2054455Fused phosphate fertilizer50.3200Tea1156.4620M.D.M200.5 belowFormaldehydeBaking soda3.90..005-0.01Microsphere catalystIon exchange resin4-70.1-0.CatalystSodium bisulfite5.80.2150108Crushing carbon13.65.3330100Flow Chart of Q/QG/JG Lees Residue Air Drier Successful Experience Overseas of KODI Q/QG/JG Lees Residue Air Flow Dryer Q/QG/JG

Lees Residue air flow dryer has a very mature technology and process,

and KODI company has rich overseas site installation experience and good after sale service .Packaging & Shipping

Другие товары поставщика

|

|

|

If you are checking battery materials vacuum dryer szg price, or looking for cheap high torque battery materials vacuum dryer szg, welcome to conta... |

|

|

|

If you are checking powder fluid bed granulator fl price, or looking for cheap high torque powder fluid bed granulator fl, welcome to contact KODI ... |

|

|

|

If you are checking protein spray dryer lpg price, or looking for cheap high torque protein spray dryer lpg, welcome to contact KODI Machinery, we ... |

|

|

|

If you are checking herbal coarse grinder csj price, or looking for cheap high torque herbal coarse grinder csj, welcome to contact KODI Machinery,... |

|

|

|

If you are checking foodstuff universal crusher wf price, or looking for cheap high torque foodstuff universal crusher wf, welcome to contact KODI ... |

Все товары поставщика

Похожие товары